High-efficiency electromagnetic ultrasonic transducer using laminated silicon steel sheet as back plate

A technology of electromagnetic ultrasound and silicon steel sheets, which is applied in the direction of material analysis, instruments, and scientific instruments through electromagnetic means, and can solve problems such as low Curie temperature, unsatisfactory improvement of conversion efficiency, and low saturation magnetic flux density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

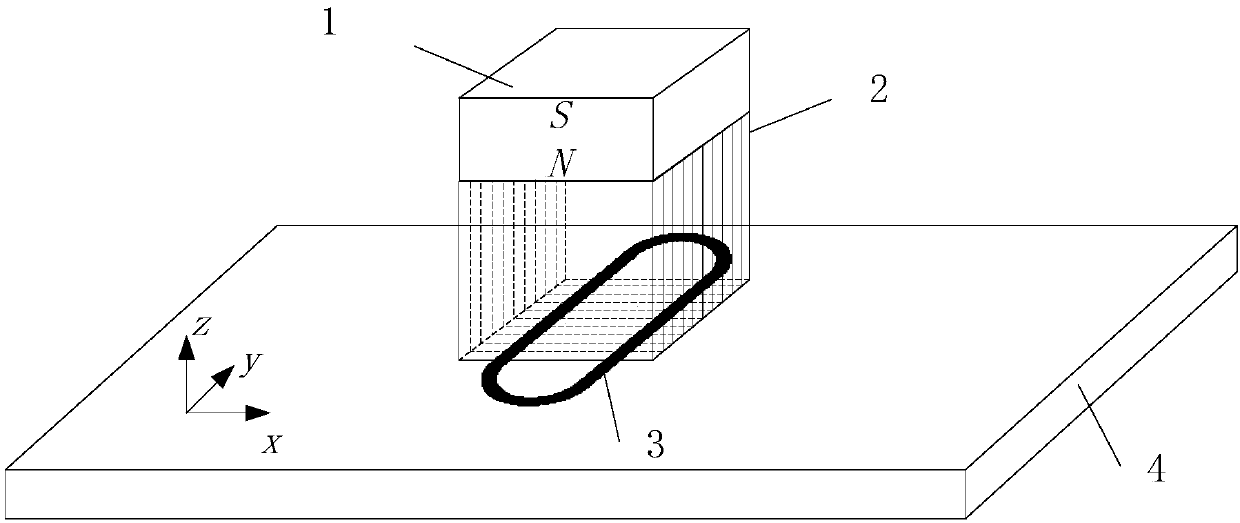

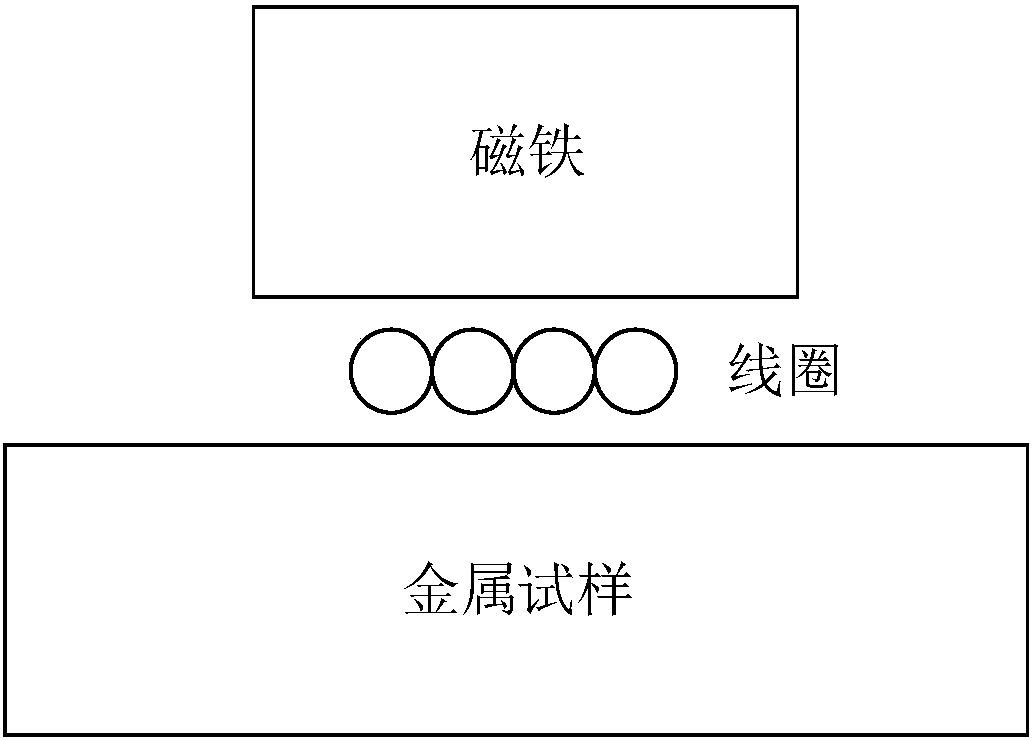

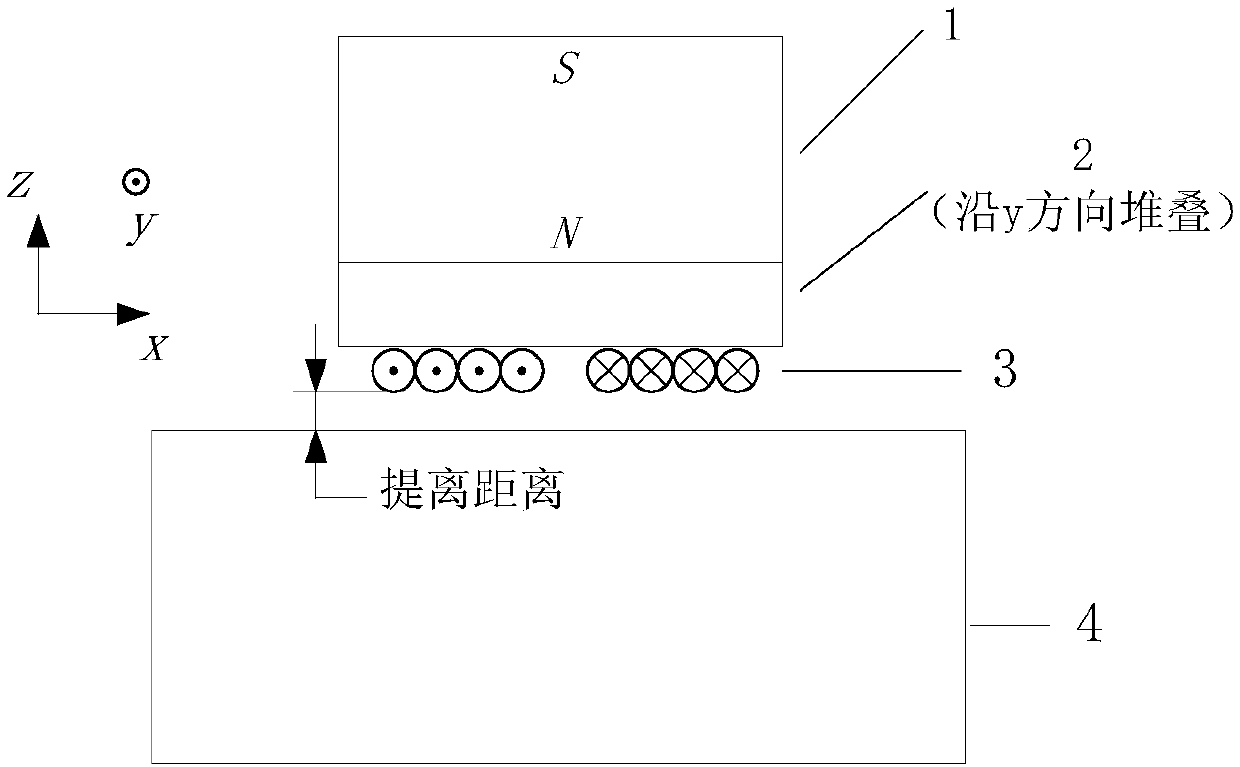

[0018] Such as figure 1 As shown, the present invention consists of a test piece (4), an excitation coil (3), a laminated silicon steel sheet (2) and a magnet (1). The excitation coil (3) is placed above the test piece (4), and the plane where the excitation coil (3) is located is parallel to the surface of the test piece (4). The excitation coil (3) can be close to the test piece (4), or keep a certain lifting distance (less than 10mm), and be electrically insulated from the test piece (4). The two ends of the excitation coil (3) are connected with the output end of the external pulse generator by wires, and the pulse current generated in the pulse generator flows through the excitation coil, generating Lorentz force and magnetostrictive force in the sample, thus causing the test The local vibration of the sample surface generates ultrasonic waves. The laminated silicon steel sheet (2) is located directly above the excitation coil (3), and the main plane of the laminated s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com