Fold-shaped compound piezoelectric energy converting structure

A composite piezoelectric and energy conversion technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve low energy conversion efficiency, low output power, vibration Small displacement and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

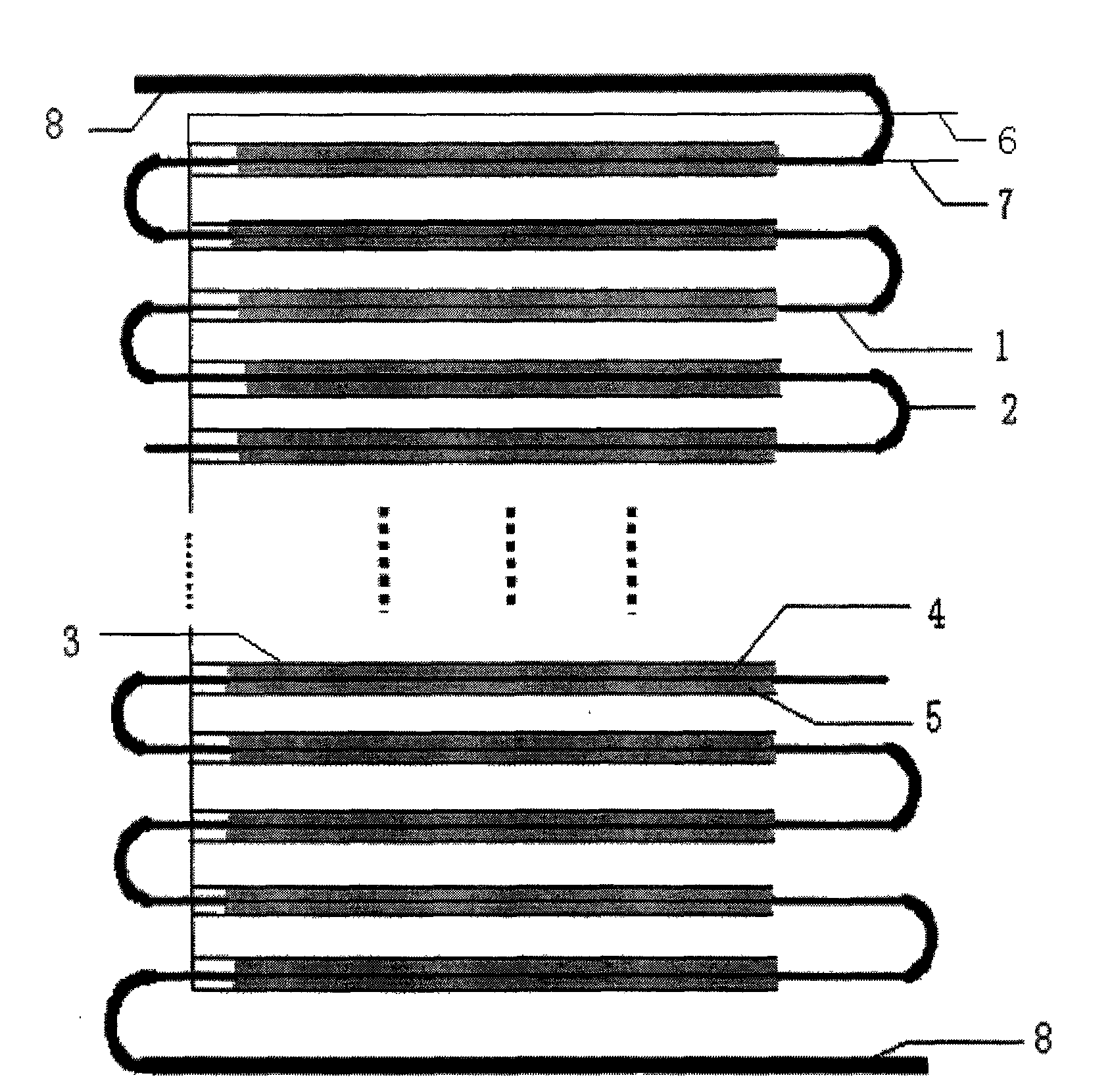

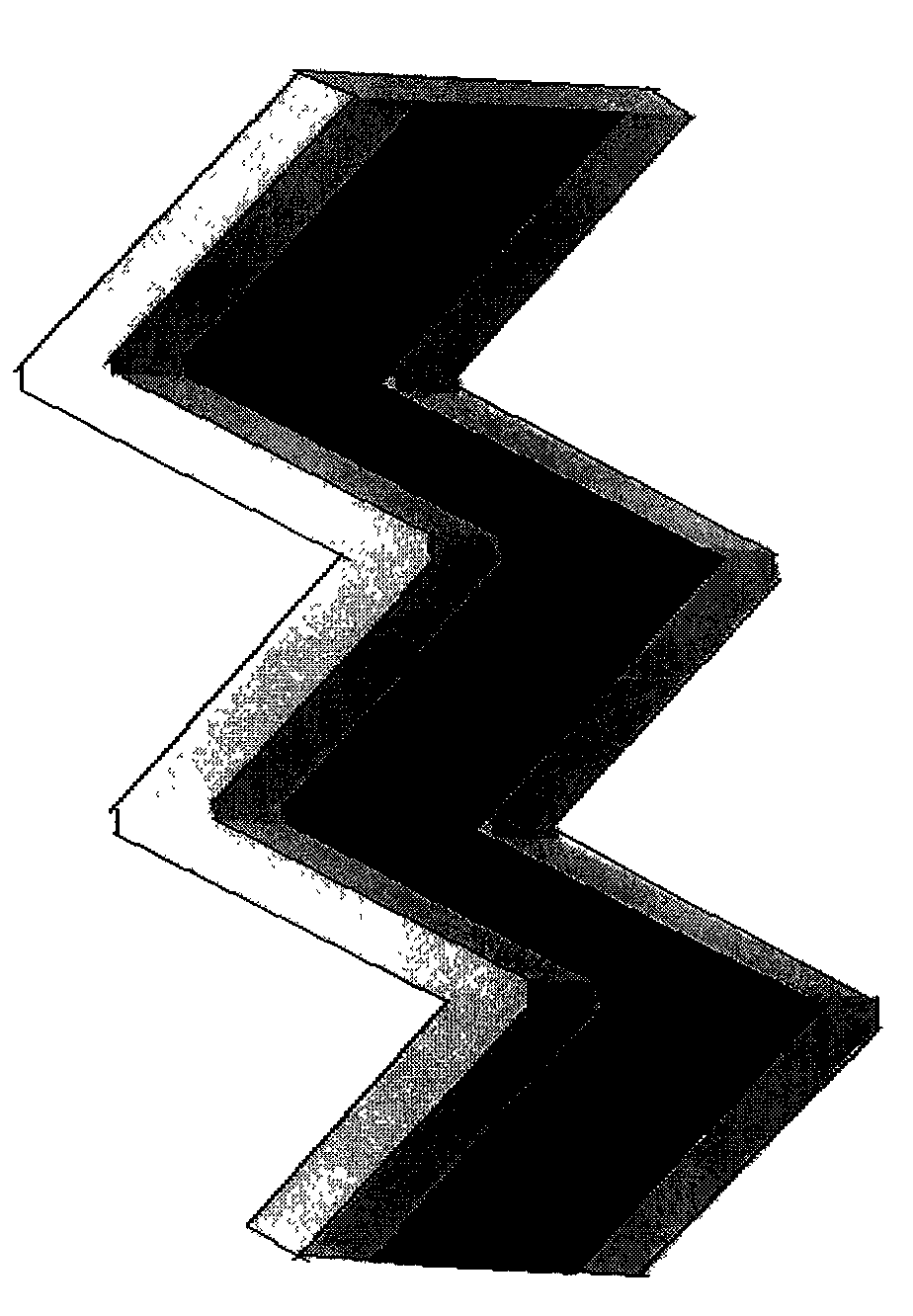

[0012] The accompanying drawing is a structural diagram of a folded composite piezoelectric energy conversion structure, with figure 1 The structure shown illustrates the specific manufacturing process of the present invention. The present invention connects the end surface 8 with other external structures through the insulating force, and the specific manufacturing process of the structure is as follows: firstly, the elastic conductor is processed into a wrinkled structure, and the shape is processed, and then the corner part of the elastic conductor is reinforced. In the next step, the upper PVDF piezoelectric film and the lower PVDF piezoelectric film are pasted on the upper and lower surfaces of the elastic conductor in the same direction with conductive glue. Next, paste the conductive glue on the surface of the exposed PVDF piezoelectric film, use the conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com