Direct-repelling type permanent magnet rotary engine

A rotor engine and permanent magnet technology, applied in the direction of generators/motors, electrical components, etc., can solve the problems of no substantial progress in development and utilization, and productivity, and achieve the effect of increasing continuity and power enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

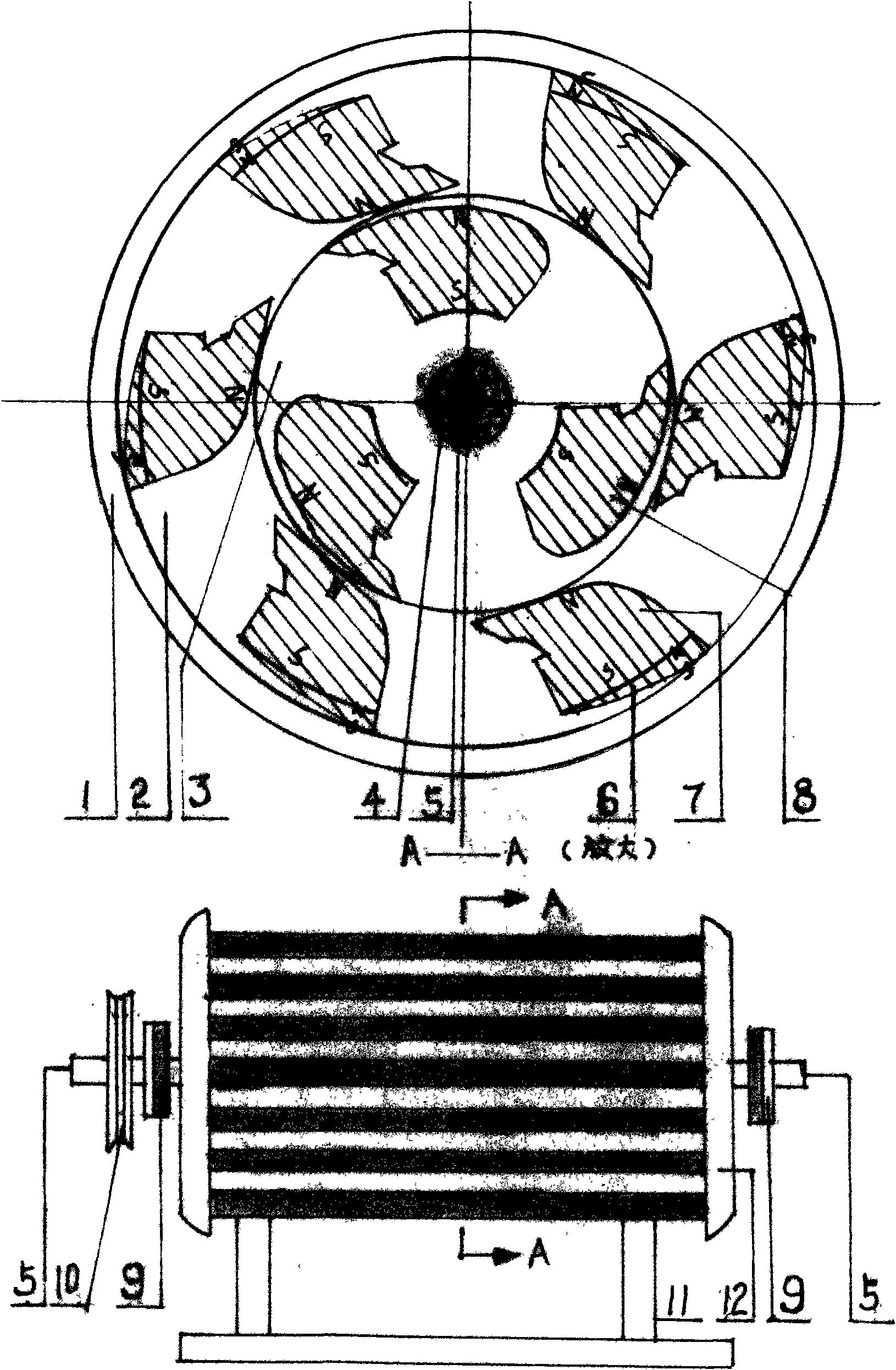

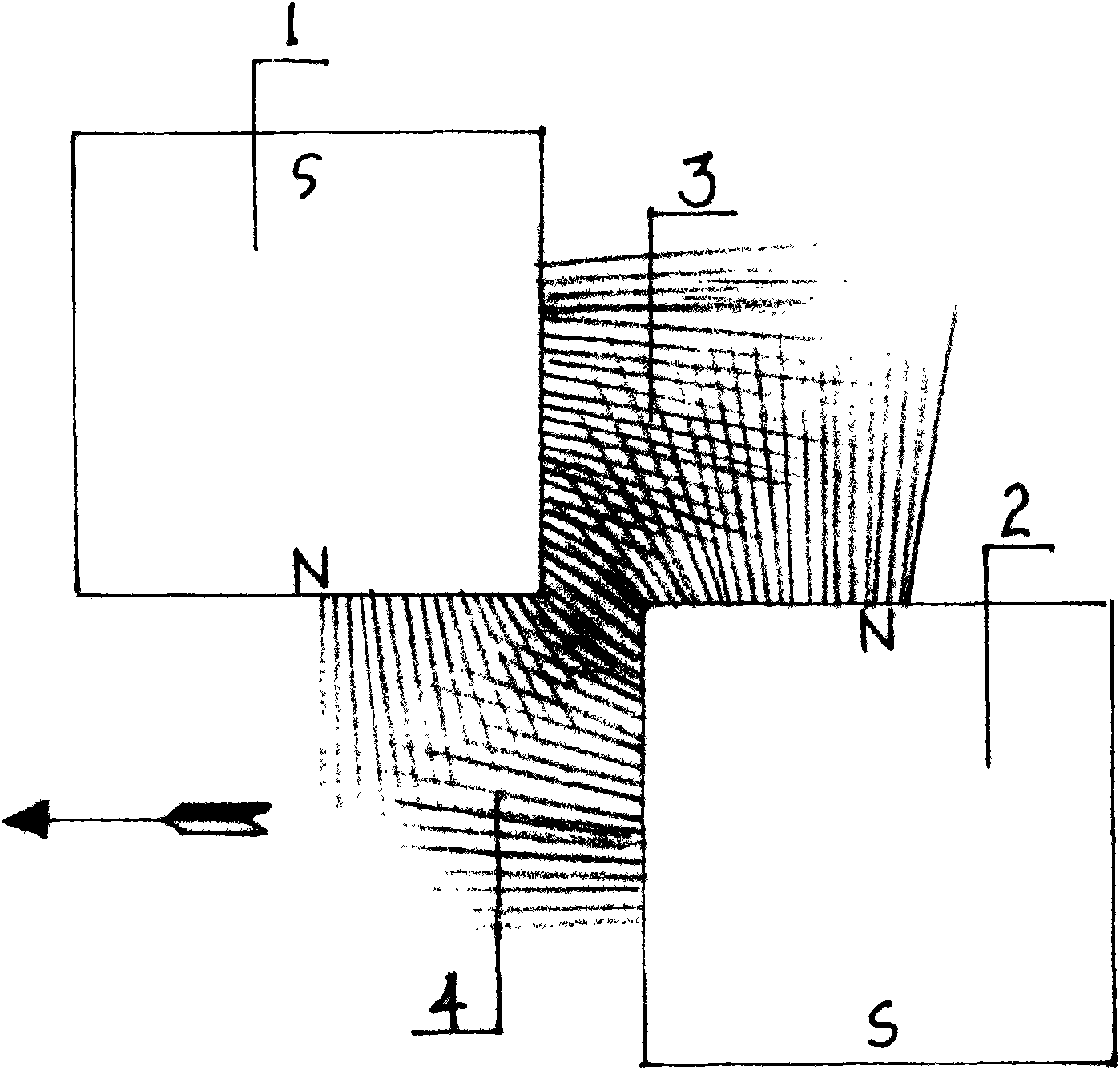

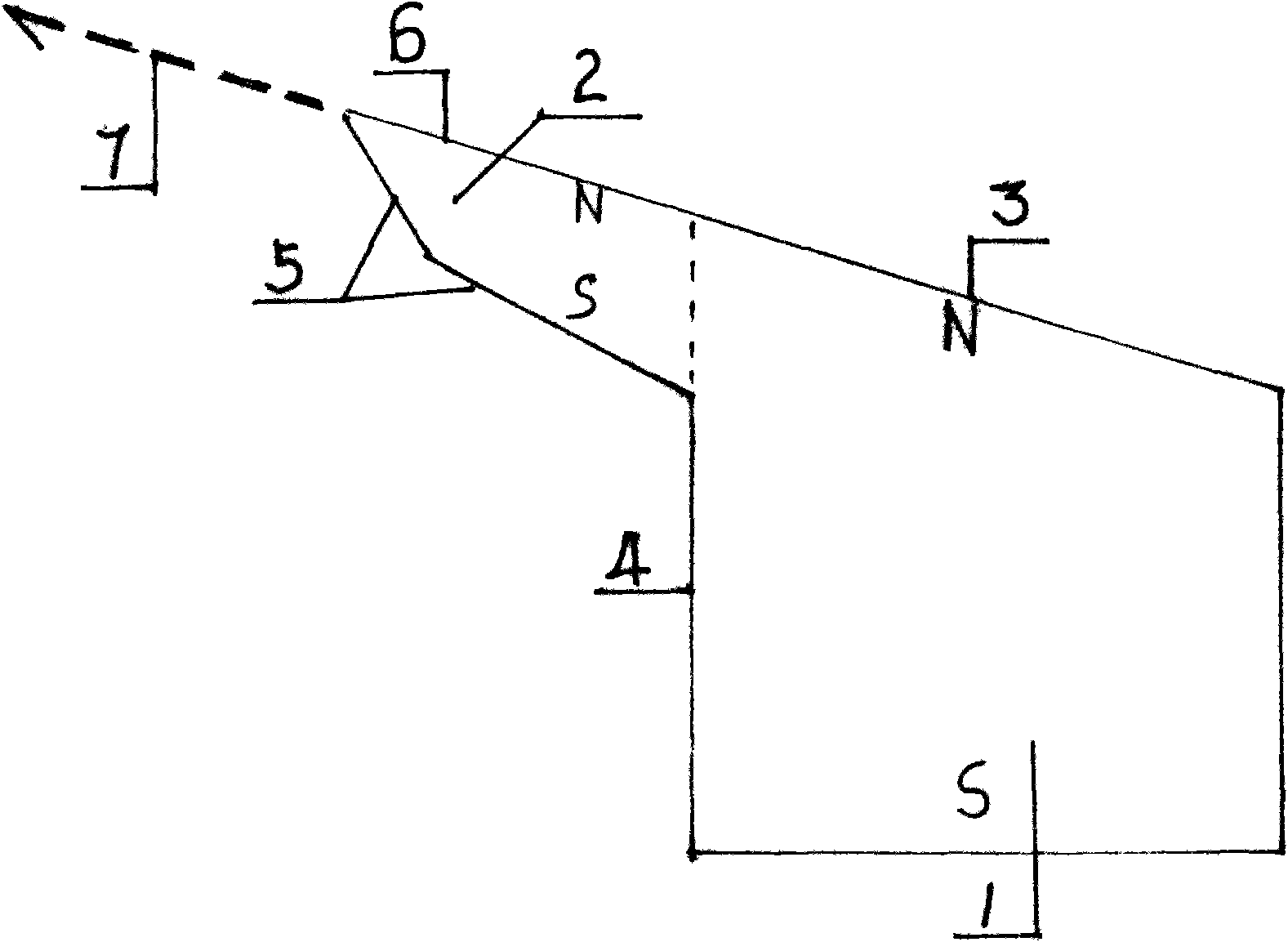

[0042] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments. figure 1 In the figure, body 1, stator 2, rotor 3, frame 11 and machine cover 12 are suitable for high-strength diamagnetic high-quality high-strength aluminum-magnesium alloy, which are manufactured by casting method and then mechanical cutting method or casting and pressing method. figure 1 In the figure, the rotating transmission shaft 4 is forged and then machined by using high-strength and good anti-magnetic stainless steel material with good wear resistance. figure 1 In the figure, the straight triangular magnetic block whose top side of the straight side extends forward and the small right triangular drag-reducing magnetic block that is connected to form a whole stator magnetic block 7, rotor magnetic block 8, and force-increasing balance magnetic block 6 adopt high-strength magnetic Gauss above 4000 The NdFeB alloy permanent magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com