Arrangement and method for the automatic sampling in a storage tank system interconnected to a pipe system for supplying cleaning fluids

一种管道系统、采样装置的技术,应用在在互连到用于提供清洁液的管道系统的存储罐系统中用于自动采样的装置和方法领域,达到防止旋转上升的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

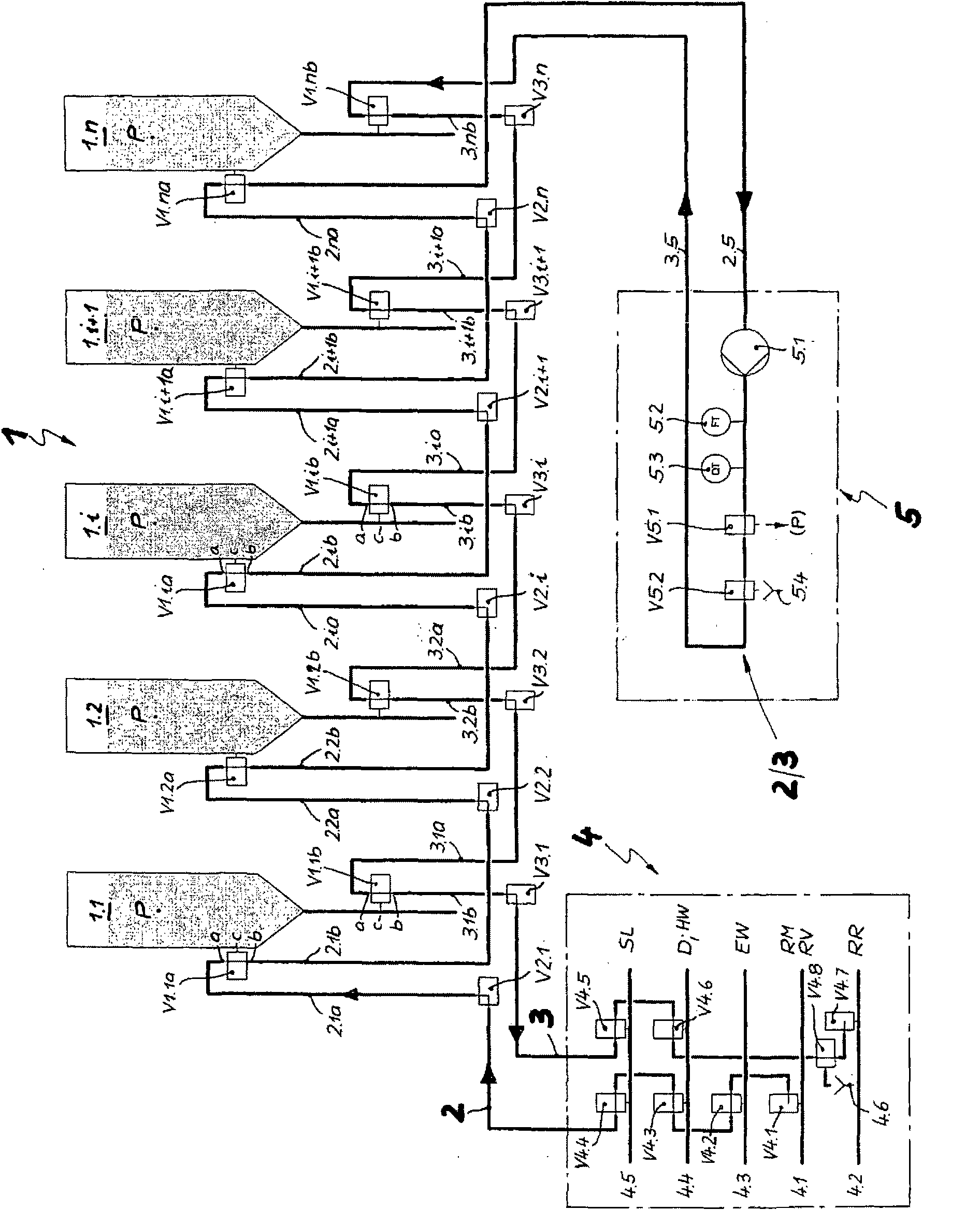

[0043] figure 1 A tank storage system 1 is shown, which in the most general case comprises n tanks, ie tanks 1.1 to 1.n. In order to prevent the length of the pipe leading to the central sampling device 5 from being too long, the maximum number of tanks assigned to the sampling device 5 should be limited to approximately n=10.

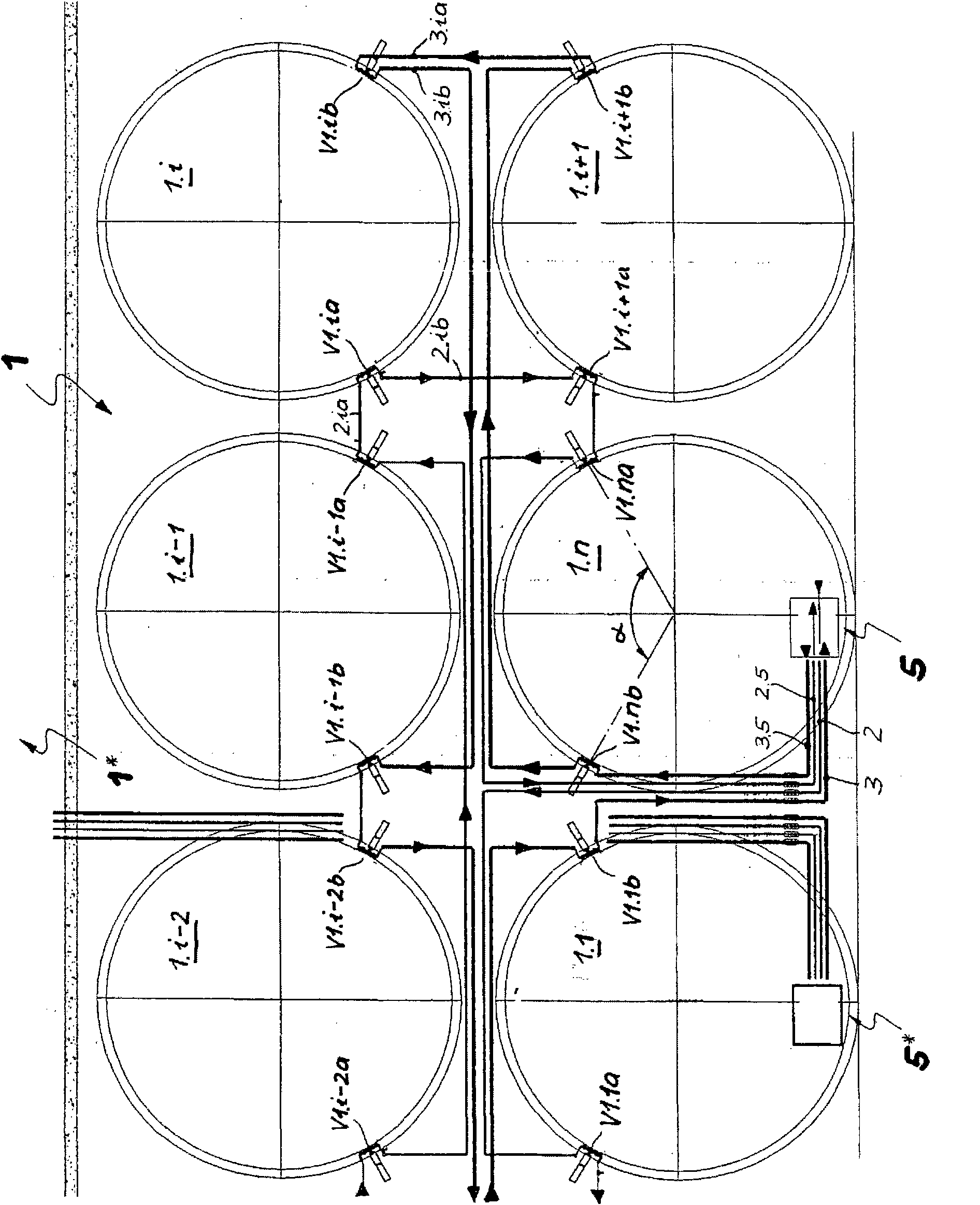

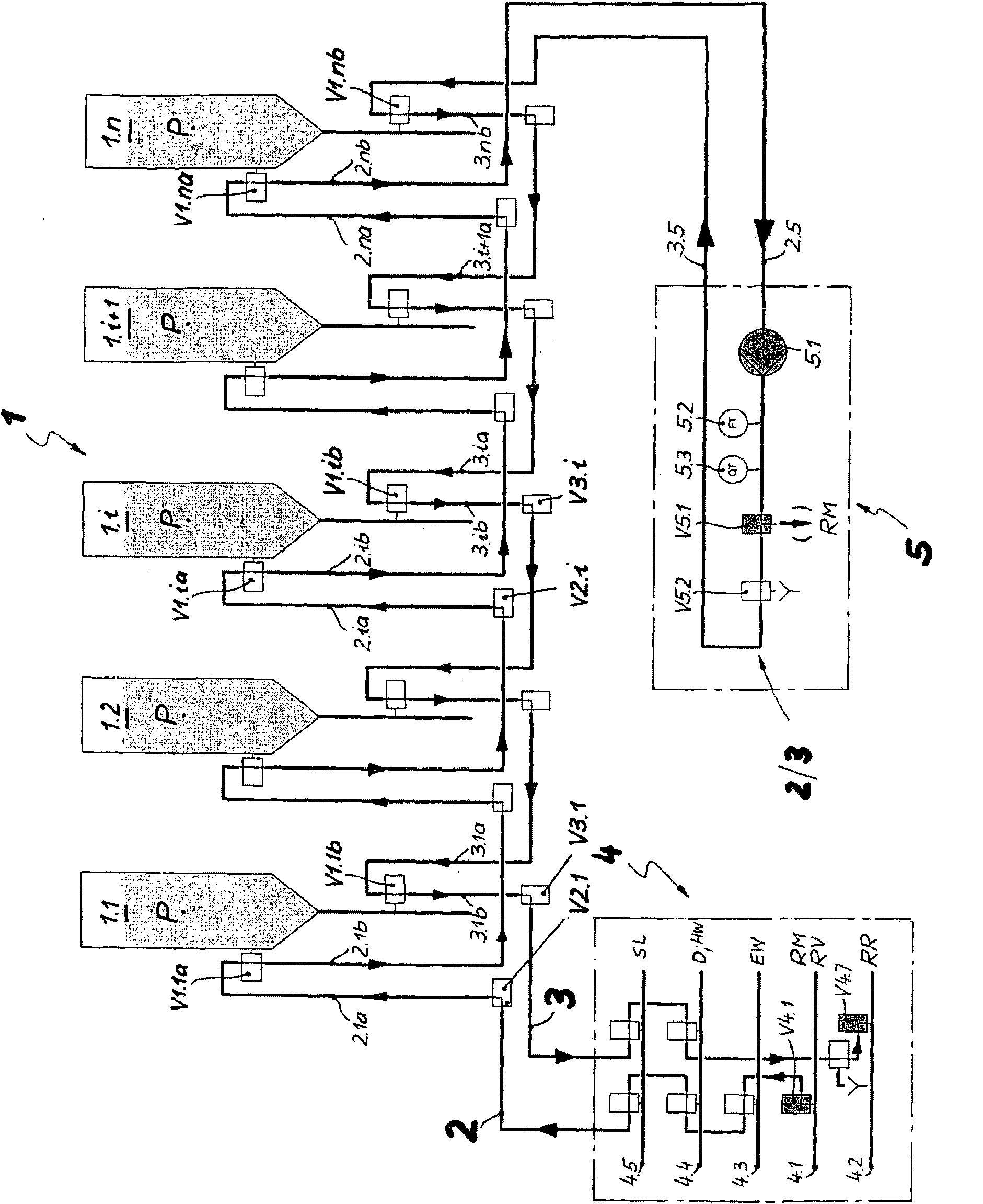

[0044] figure 2 shows the actual piping of the respective tanks 1.1 to 1.n, while figure 1 Only a schematic diagram of the piping is shown to illustrate the function. In this case n=5, figure 1 Cans 1.1 to 1.n are shown in , where the third can from the left generally has the reference 1.i and the adjacent tank to the right generally has the reference 1.i+1. figure 2 The full number of tanks connected to the central sampling device 5 is not shown. However, it states that the tank 1.1 and finally the tank 1.n are arranged directly next to each other into the current matrix form arrangement of more than 6 tanks.

[0045] Each of jars 1.1 to 1.n (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com