Negative pressure CO2 concentration control type honeycomb culture system

A cultivation system and control system technology, applied in the field of integrated cultivation systems, can solve the problems of inability to form negative pressure, inability to integrate equipment, inability to cultivate viruses, etc., to enhance scalability, realize mass production management, increase effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

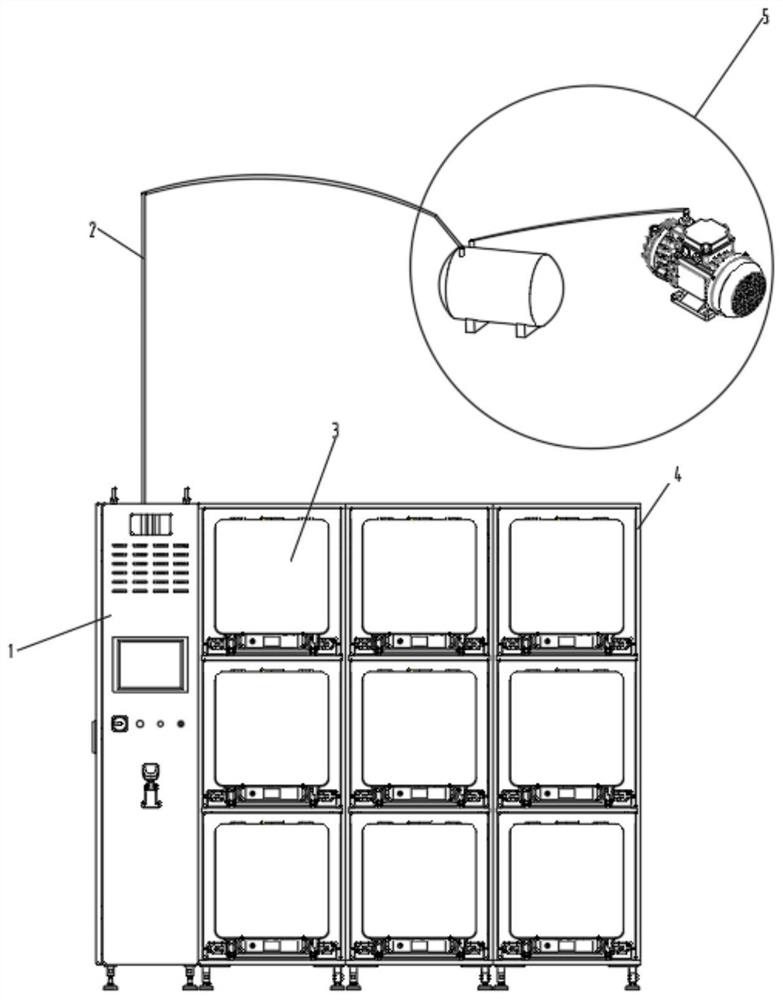

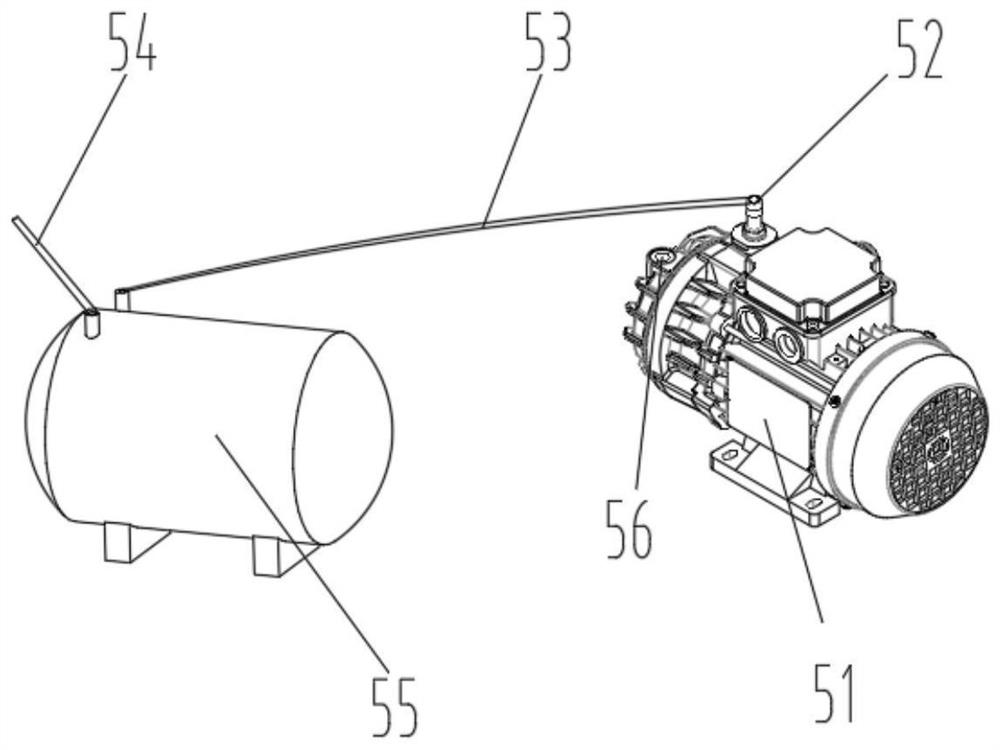

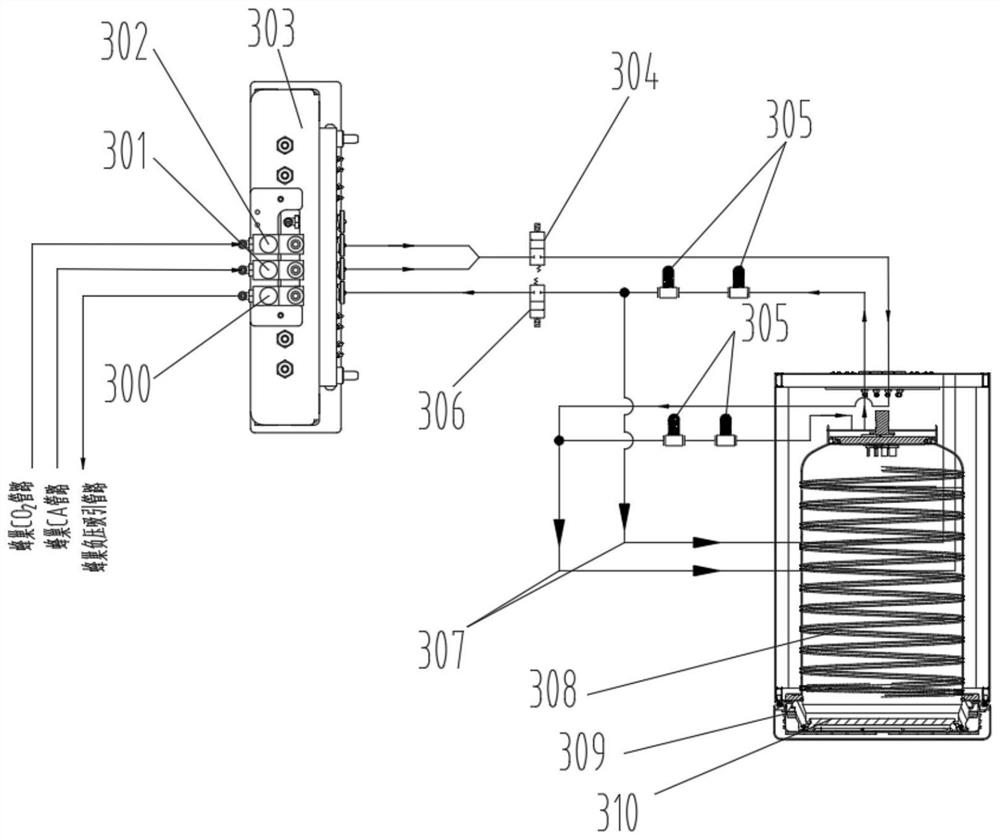

[0017] Such as Figure 1 to Figure 3 As shown, a negative pressure CO of the present invention 2 Concentration-controlled hive culture system mainly consists of electrical cabinet 1, negative pressure pipeline 2, RTP negative pressure CO 2 The incubator 3, the module assembly 4 and the vacuum automatic control system 5 are composed. RTP negative pressure CO 2 The incubator 3 is placed in the module assembly 4, RTP negative pressure CO 2 The incubator 3 is connected to the vacuum automatic control system 5 through the negative pressure pipeline 2, and the RTP negative pressure CO in the multiple module components 4 and the module components 4 2 The incubators 3 are stacked together to form a honeycomb incubator, and the electrical cabinet 1 is connected to the module assembly 4 and the RTP negative pressure CO in the module assembly 4 2 The incubato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com