Wire rope flaw detector

A flaw detection device and steel wire rope technology, applied in the direction of material magnetic variable, etc., can solve the problems of reduced induced voltage, reduced SN ratio, difficult detection, etc., and achieve the effects of increased magnetic flux leakage, extended magnetic circuit length, and enhanced number of turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

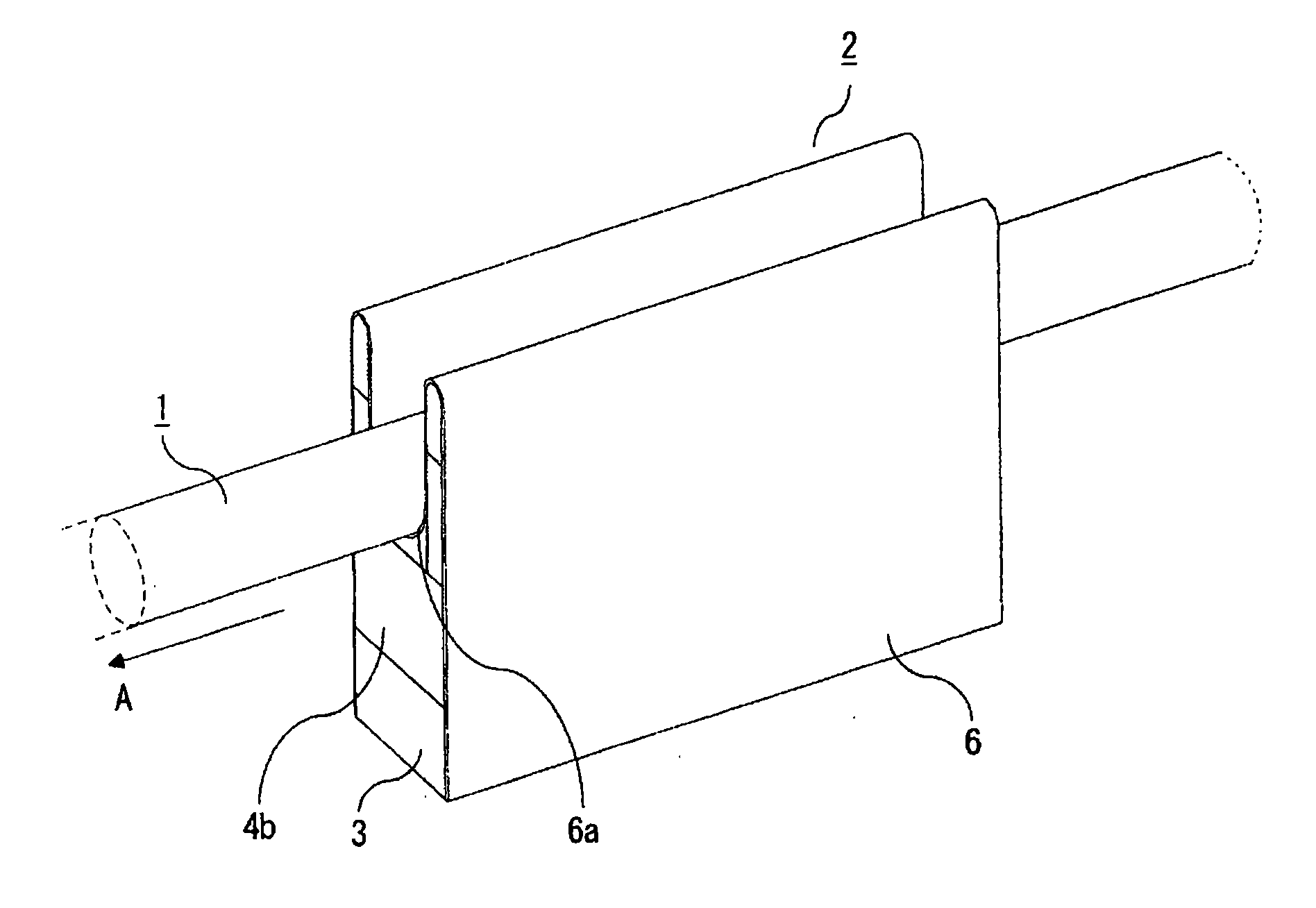

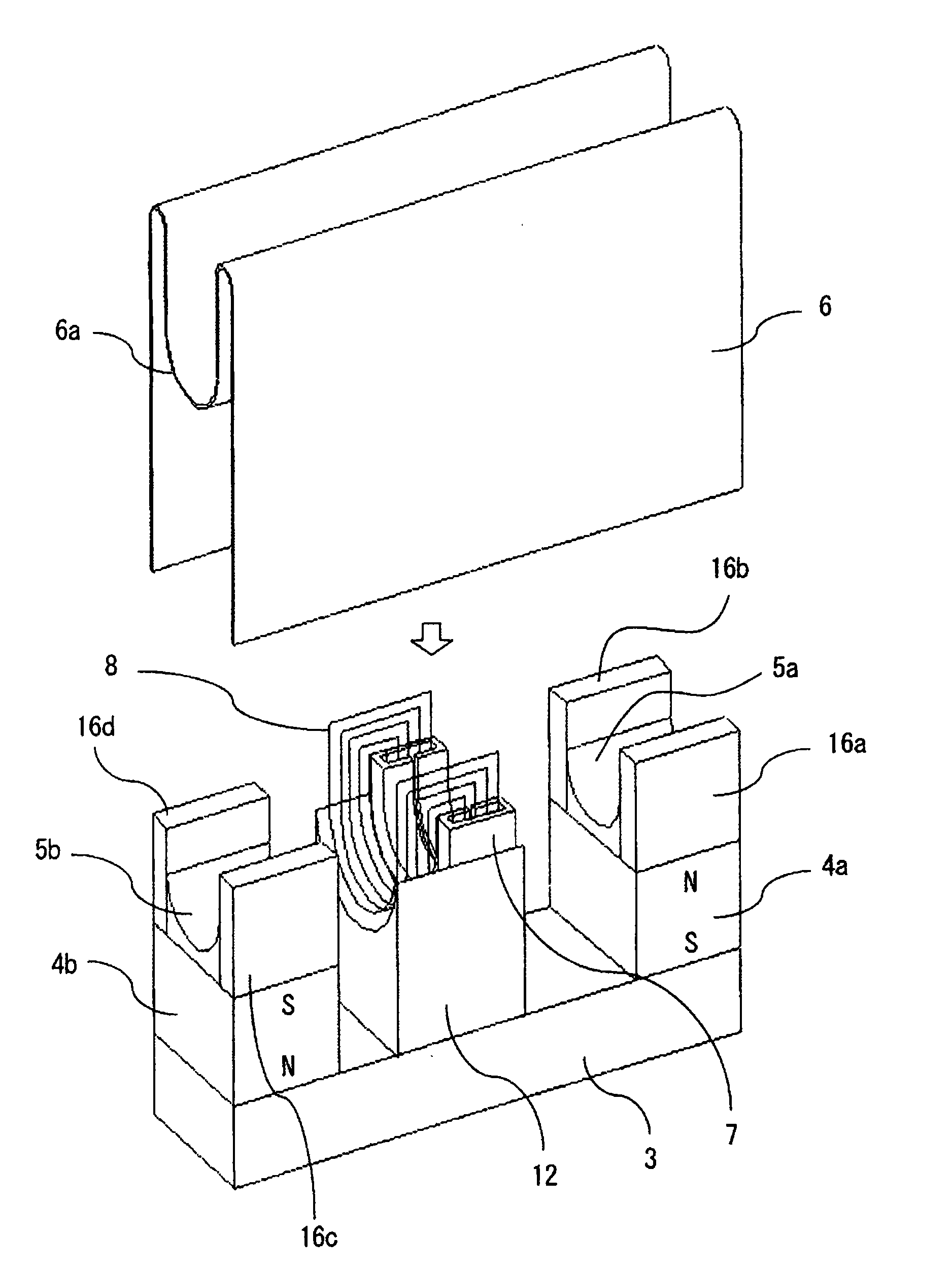

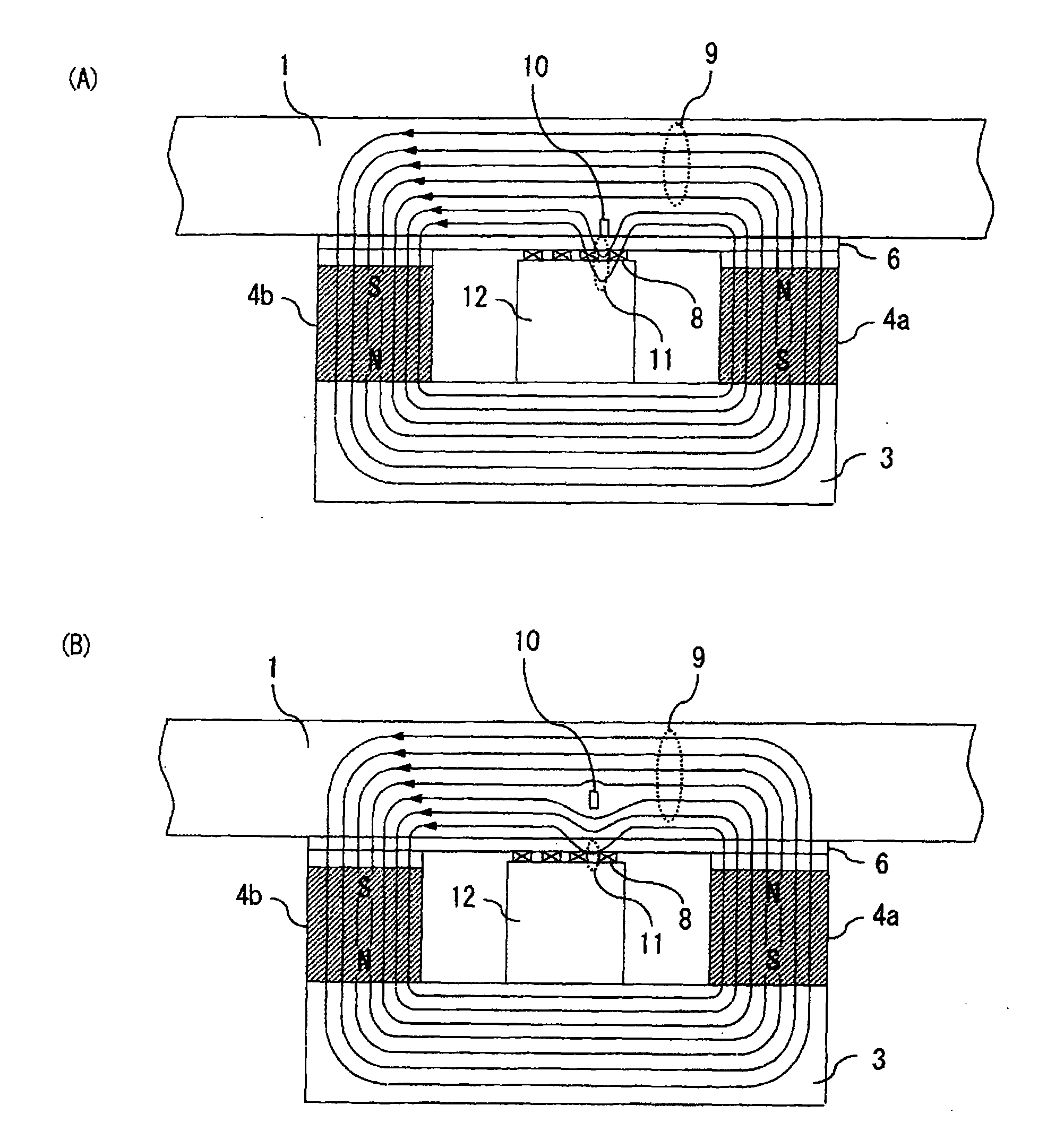

[0035] figure 1 is a perspective view showing a wire rope flaw detection device according to Embodiment 1 of the present invention, figure 2 means removed figure 1 A perspective view of the guide plate 6 of the wire rope flaw detection device. In the drawing, the wire rope flaw detection device 2 includes a guide plate 6 having a substantially U-shaped guide groove 6a through which the wire rope 1 travels (shown in A). The wire rope flaw detection device 2 of this embodiment forms a main magnetic circuit in a predetermined section in the axial direction of the traveling wire rope 1 through a magnetizer, and at the same time makes the leakage magnetic flux generated by the damaged part of the wire rope 1 go around the outside of the wire rope 1 through the magnetic circuit member 7 , the leakage magnetic flux is detected by the detection coil 8 wound around the magnetic circuit member 7 .

[0036] The magnetizer of the steel wire rope flaw detection device 2 is used to fo...

Embodiment approach 2

[0054] Figure 19 It is a perspective view showing the state when the guide plate is removed in the wire rope flaw detection device according to Embodiment 2 of the present invention. In Embodiment 1 above, as the magnetizer of the wire rope flaw detection device, the back yoke 3 made of a ferromagnetic material and a pair of excitation magnets arranged opposite to each other in polarity are shown at both ends of the back yoke 3 . Magnetizers for permanent magnets 4a, 4b. In this embodiment, if Figure 19 As shown, as the magnetizer of the wire rope flaw detection device, it is equipped with a back yoke 3 made of a ferromagnetic material, a pair of excitation electromagnets 17a that are excited in such a way that their polarities are opposite to each other at both ends of the back yoke 3, 17b. In this way, even if the permanent magnet used in the magnetizer of the first embodiment is replaced with an electromagnet, the same effect as that of the first embodiment can be obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com