System and method for deliverying laser beam and laser lift-off method using the same

A transmission system and laser beam technology, applied in laser welding equipment, electrical components, circuits, etc., can solve the problems of uniformity limitation of energy intensity, increase of manufacturing cost, laser beam can not penetrate, etc., to improve beam transmittance , The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The invention will be described in more detail below with reference to the accompanying drawings, in which exemplary embodiments are shown.

[0050] It should be understood that, in addition to what is described and illustrated below, the laser beam delivery system further includes optional optical elements, such as mirrors, which are also within the scope of the present invention.

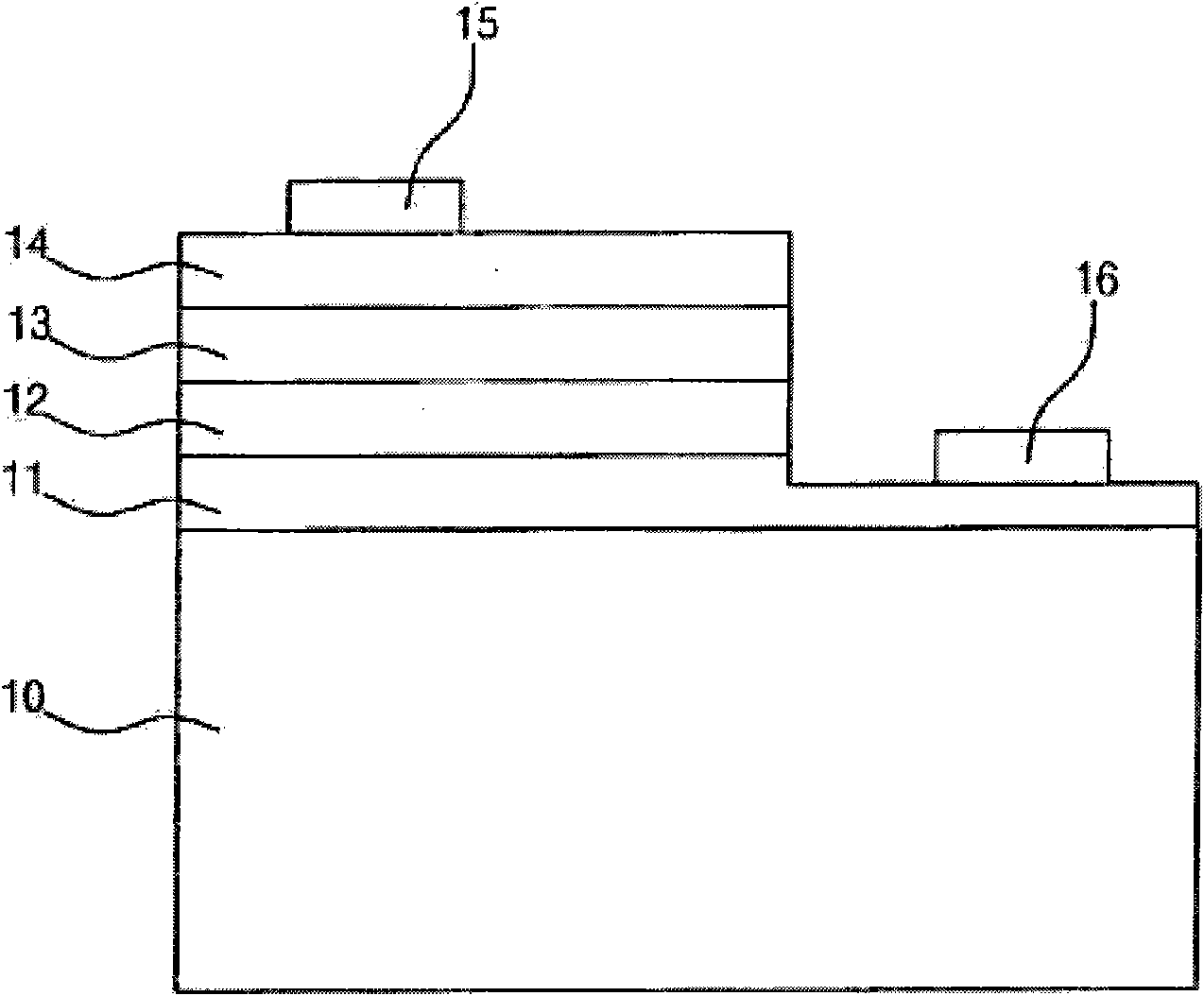

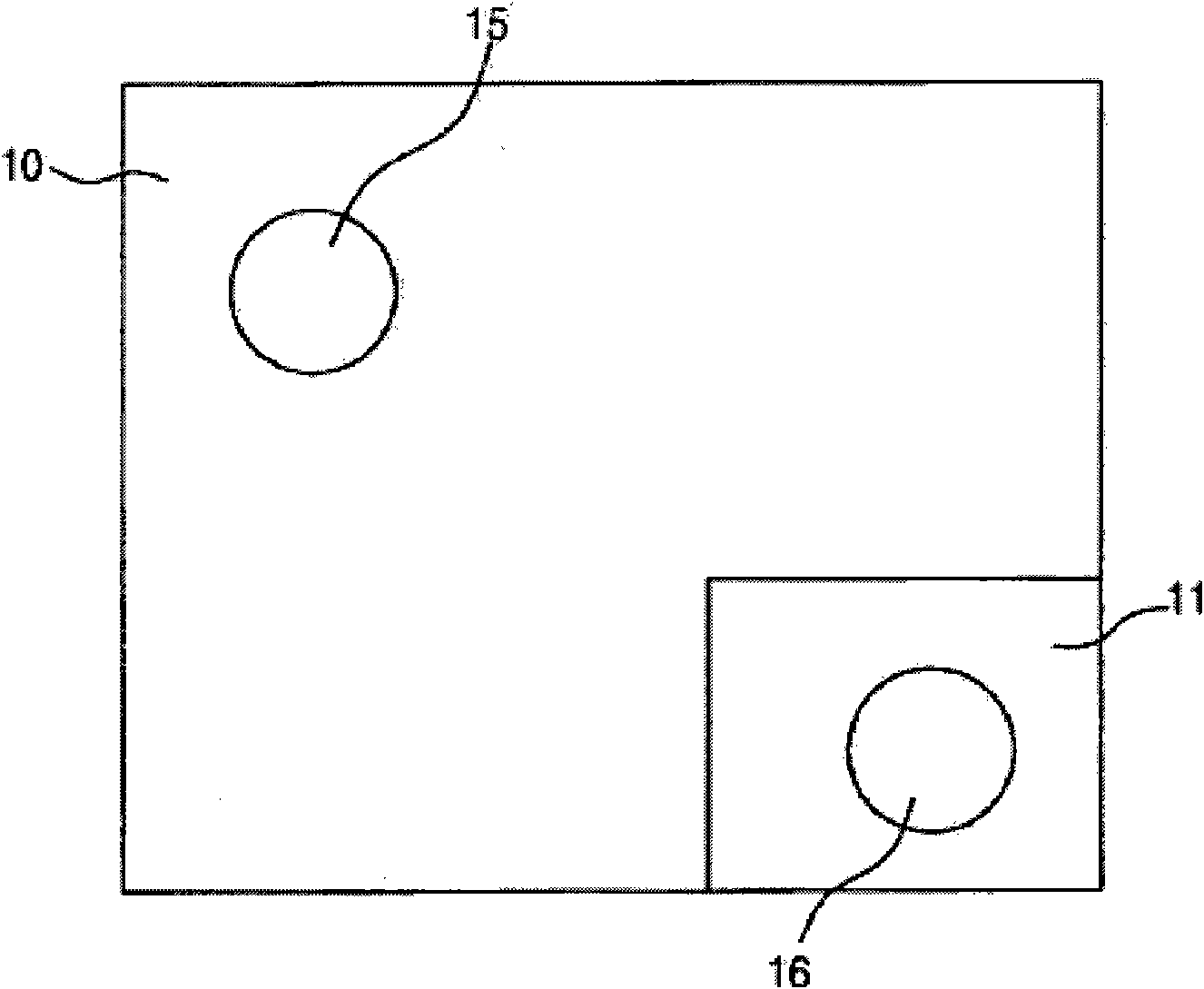

[0051] Figure 8 to Figure 14 is a sectional view showing a method of manufacturing a vertical type LED according to the present invention.

[0052] refer to Figure 8 , including a GaN buffer layer 31, an N-type GaN layer 32, an InGaN (indium gallium nitride) / GaN / AlGaInN (aluminum gallium indium nitride) active layer 33 with multiple quantum wells, and a P-type GaN layer 34 The composition layer 30 is sequentially formed on the sapphire substrate 20 using conventional semiconductor techniques such as MOCVD (Metal Oxide Chemical Vapor Deposition) and MBE (Molecular Beam Epitaxy, Molecular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap