Multifunctional threshing device of combine harvester

A combine harvester and threshing device technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of high crushing rate of rapeseed and soybean, large blow, poor cleanliness of rapeseed and soybean, etc., and achieve regulation Convenient and rapid, low entrainment loss rate, and the effect of improving the threshing separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

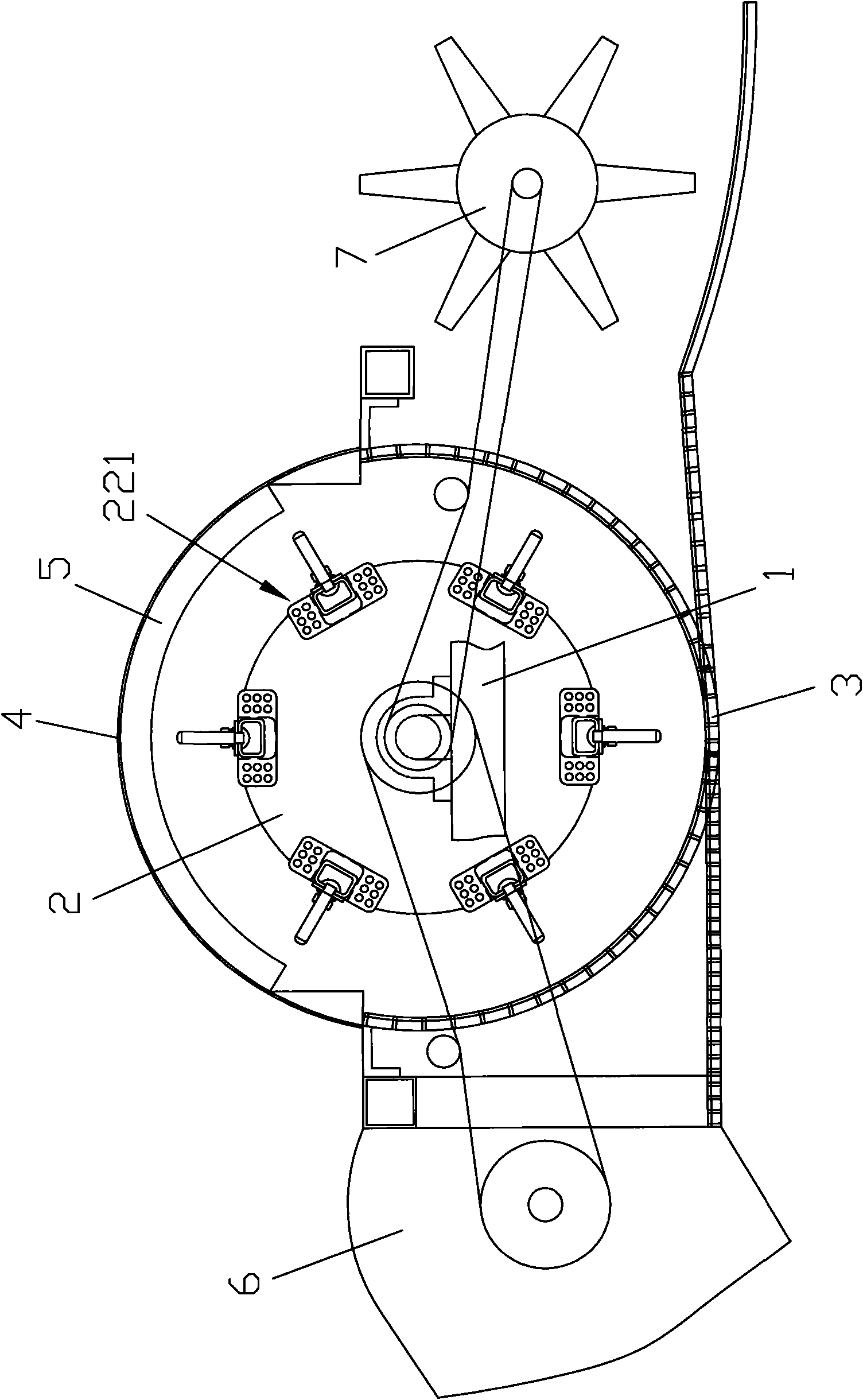

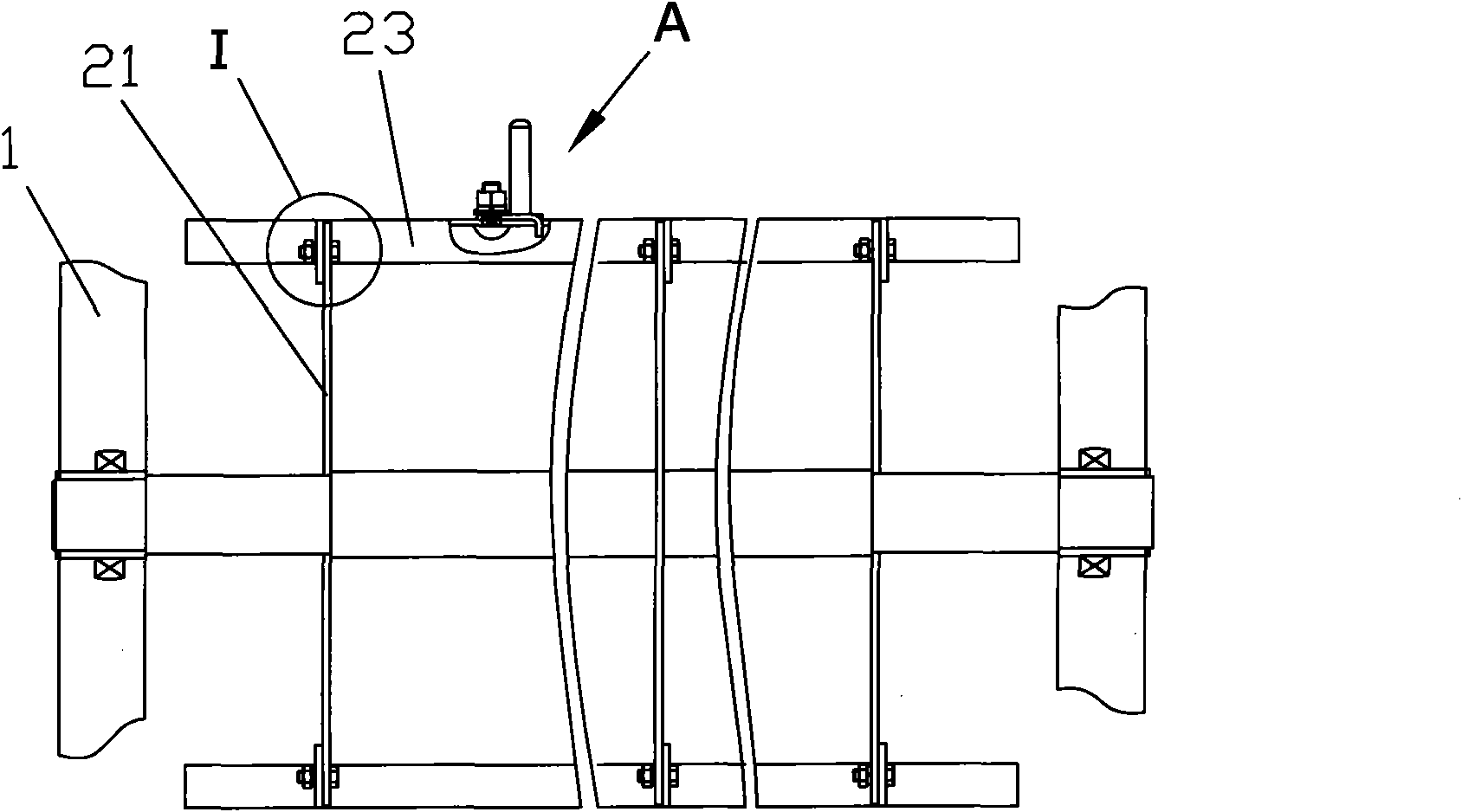

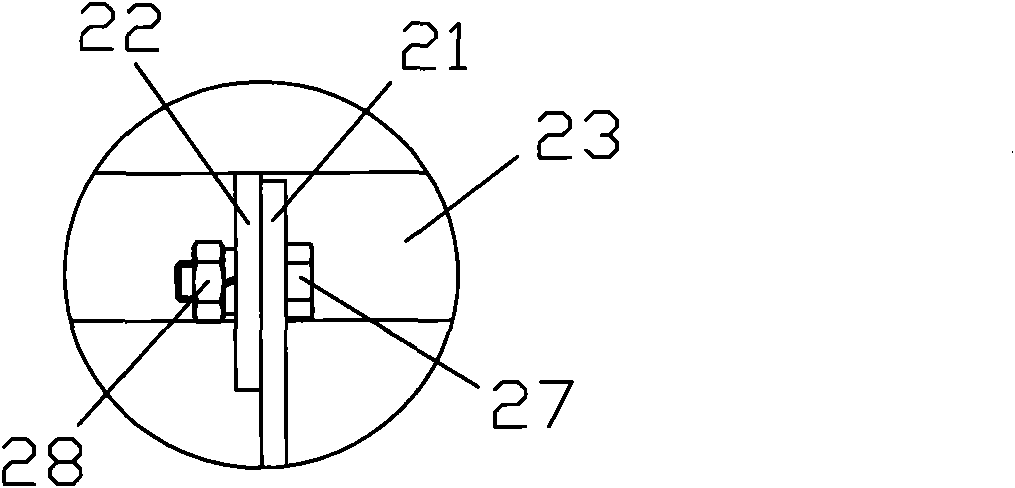

[0033] Such as Figures 1 to 17 As shown, it is a multifunctional threshing device of a combine harvester of the present invention, including a threshing cylinder frame 1, which is installed on the chassis of the combine harvester, and the threshing cylinder frame 1 is provided with a threshing cylinder 2 and a threshing cylinder top cover 4. There are several screw holes on the top cover 4 of the threshing drum in the circumferential direction (the screw holes are not shown in the accompanying drawings), through which 2 to 4 grass guide ribs 5 are connected, and the grass guide ribs 5 pass through bolt III (bolt III). III is not drawn in accompanying drawing) is connected on different screw holes to adjust angle, adjusts the angle of guiding grass rib 5 and can change the threshing time of crop in the threshing device, can set guiding grass rib 5 angles according to actual conditions. The bottom of the threshing drum 2 is equipped with a concave screen 3, the concave screen 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com