A high-throughput threshing and cleaning device for ratooning rice combine harvester

A combine harvester and cleaning device technology, which is applied to harvesters, threshing equipment, agricultural machinery and implements, etc., can solve problems such as limiting the space of cleaning devices, increasing the cleaning workload, and blocking the cleaning screen surface. Achieve the effects of reducing power consumption and grain loss rate, high throughput and efficient cleaning, and high energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

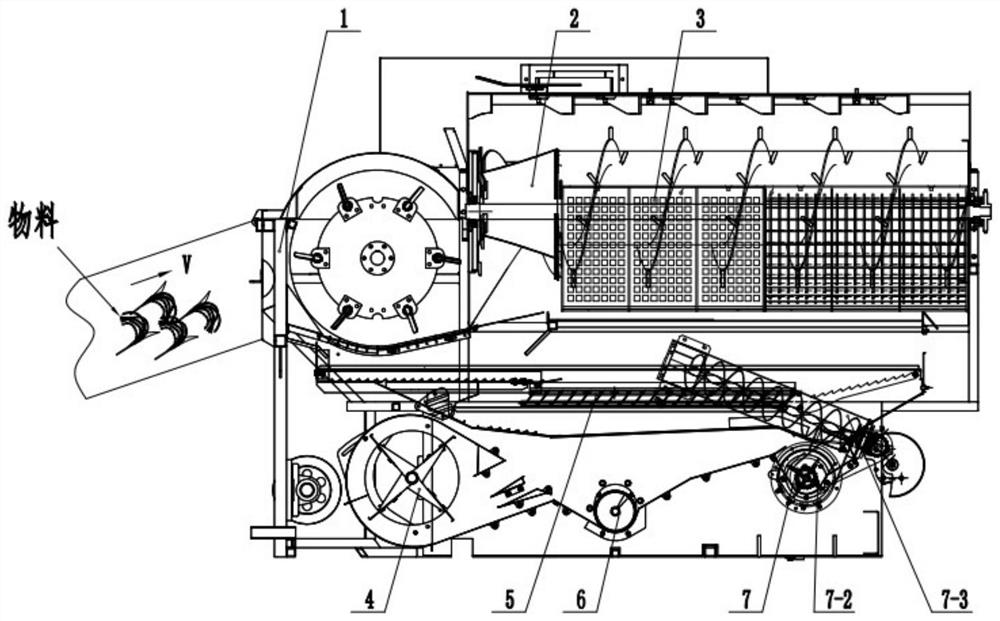

[0028] Such as figure 1 As shown, the high-throughput threshing and cleaning device of the ratooning rice combine harvester described in the present invention is applied to the harvest of the first season ratooning rice with short stems and small grass-to-grain ratio during high stubble retention operations. The high stubble operation means that after being harvested by the header, what enters the conveying and threshing device is mainly the ear head of regenerated rice, with short stems and a small grass-to-grain ratio, generally 0.3-0.8.

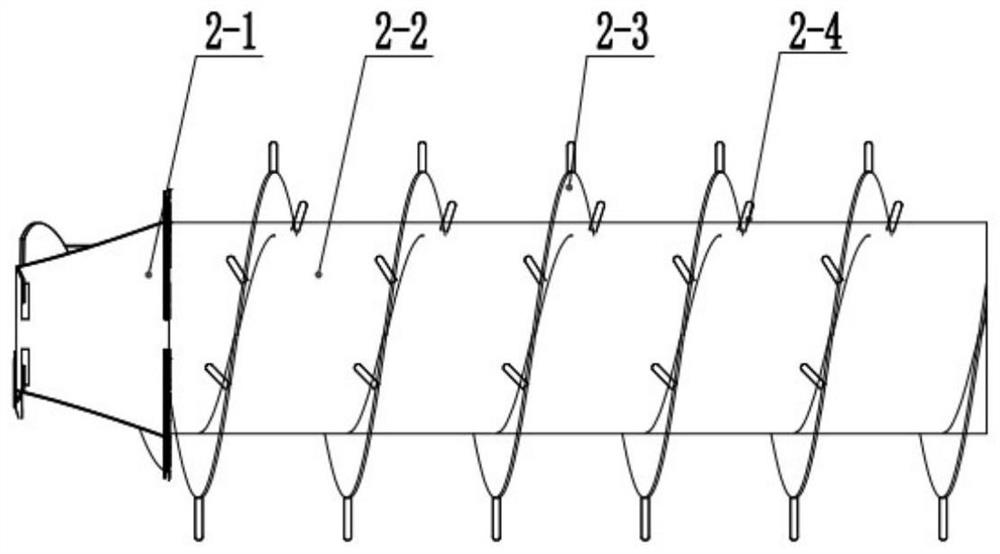

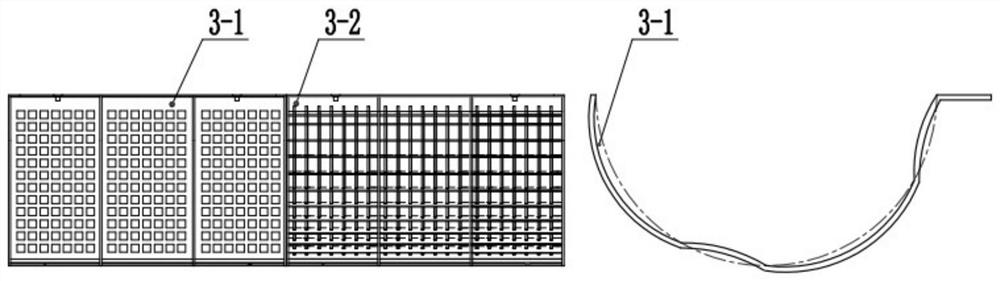

[0029] The high-throughput threshing and cleaning device of the ratooning rice combine harvester according to the present invention comprises a frame 1, a threshing cylinder 2, a corrugated punching-grid concave screen 3, a cleaning f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com