Smoke-air duct shocking casting machine

A casting machine, flue gas technology, applied in the direction of manufacturing tools, ceramic molding machines, molds, etc., can solve the problems of inability to achieve efficient production, high mold production cost, low production efficiency, etc., to solve the problem of low production efficiency and simplify operation. , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

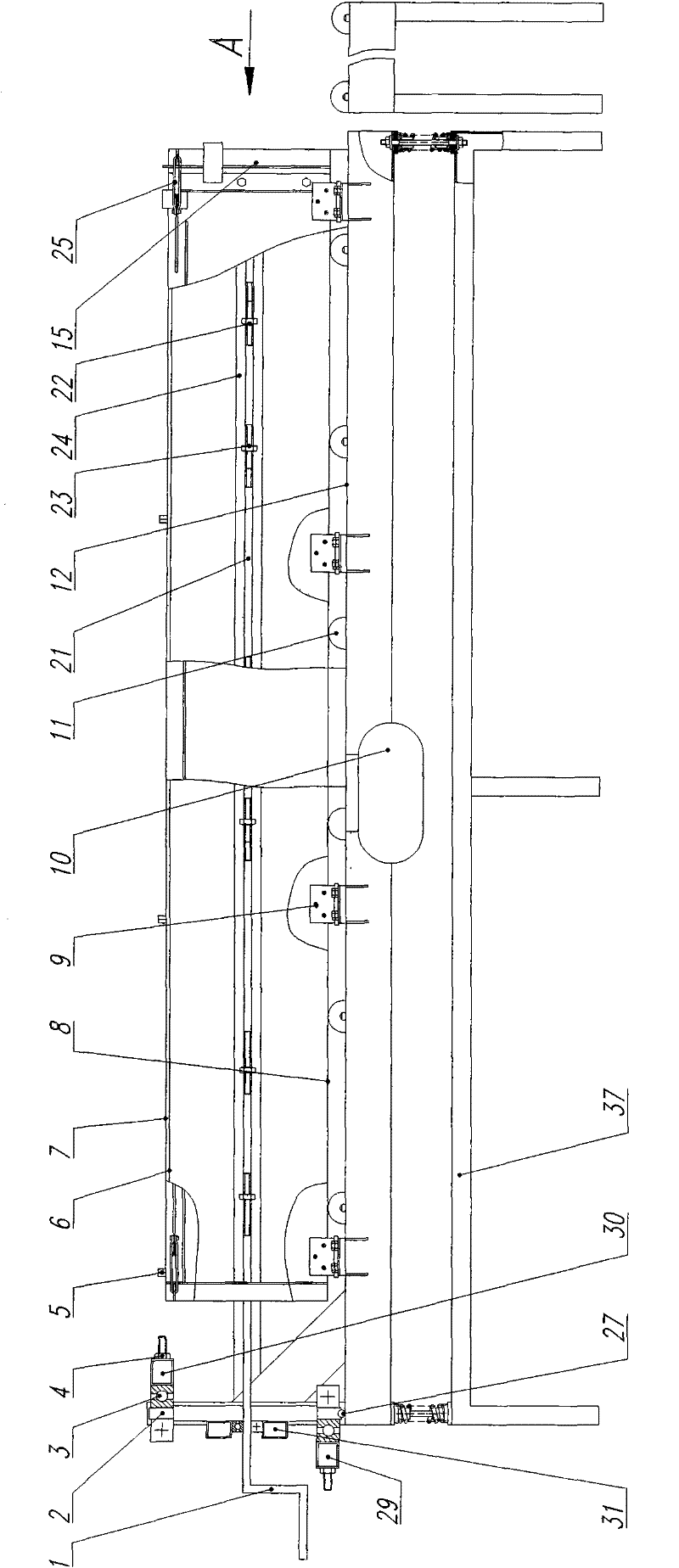

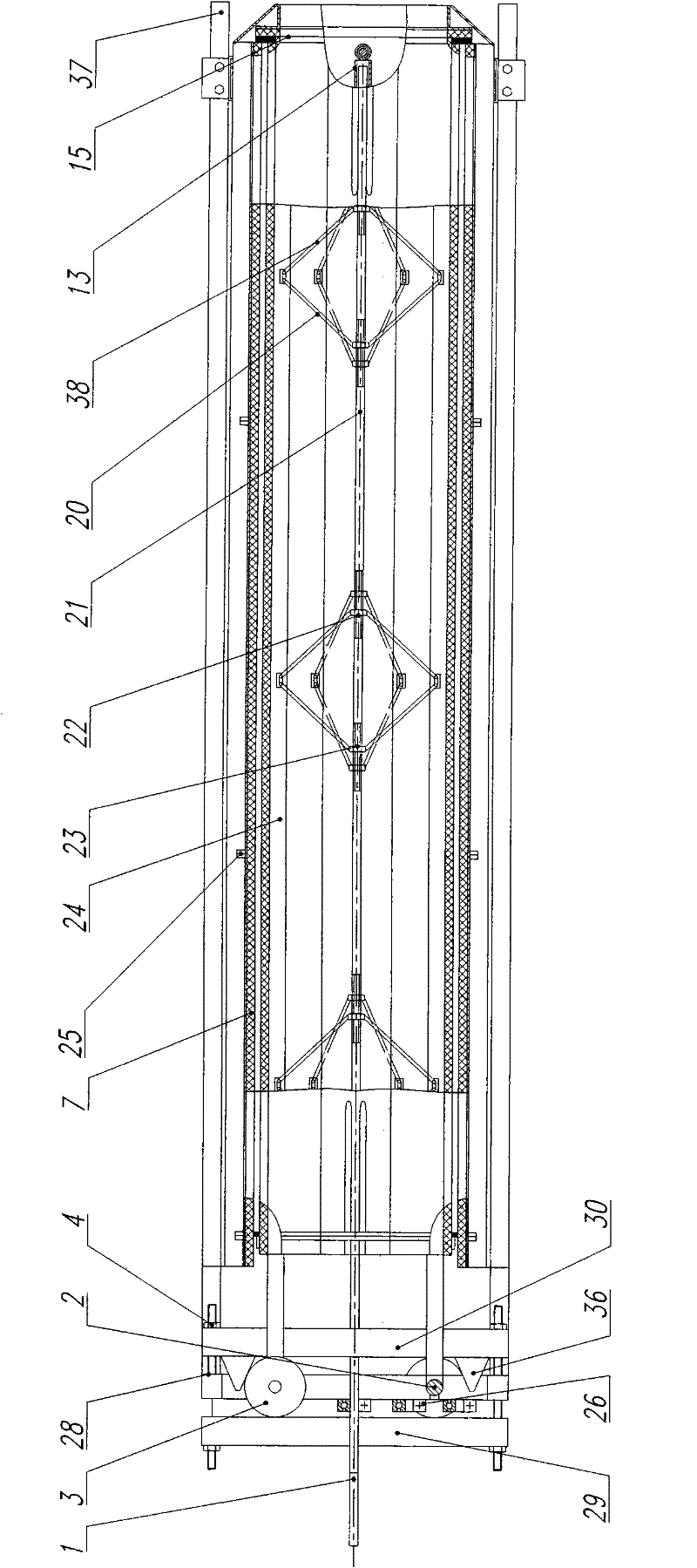

[0025] see figure 1 with figure 2 , the flue gas duct vibration casting machine includes a machine base 37, an upper frame 12, an outer mold mechanism, an inner mold mechanism and a flat vibration pump 10; the vibration pump 10 is installed on the bottom of the upper frame 12, so that the cement mortar is evenly distributed, ensuring the production efficiency The wall thickness of the flue gas channel is uniform.

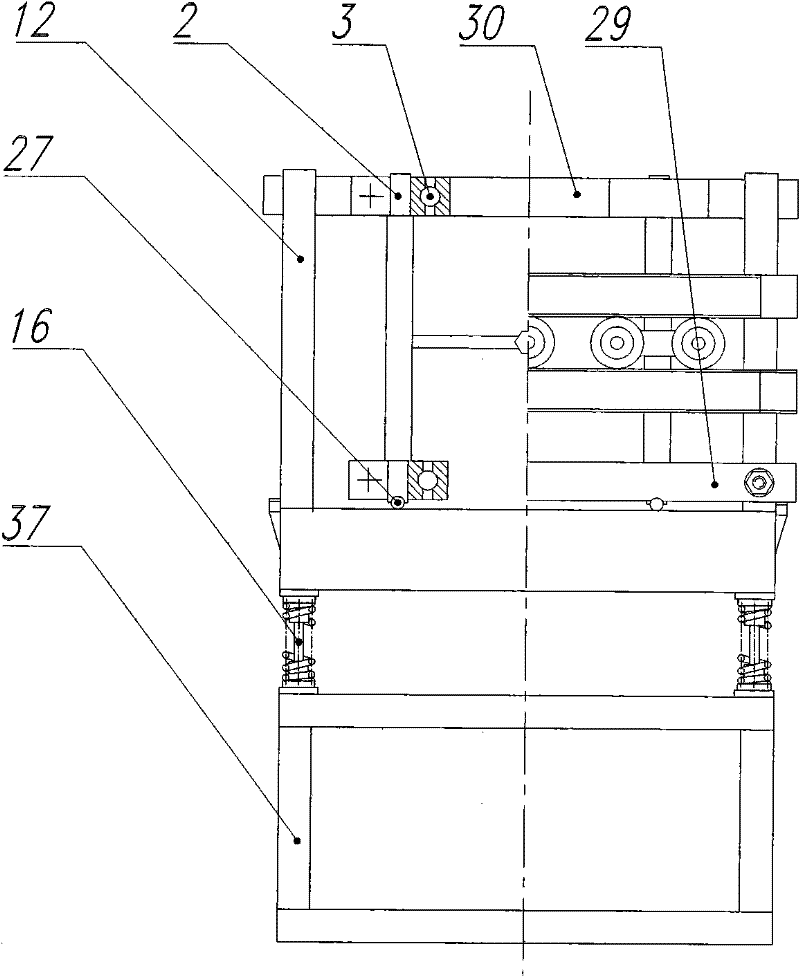

[0026] The frame 37 is a rectangular frame shape; the upper frame 12 is a ladder-shaped frame corresponding to the top surface of the frame, and is positioned on the top surface of the frame, between the four corners of the frame 37 and the corresponding upper frame 12 and the middle part. Support springs 16 are installed respectively between each support spring 16 middle parts, and the central shaft connecting the upper frame and the support is installed. On the width direction of upper frame 12, supporting roller 11 is installed in parallel evenly; One end of u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com