Method for controlling automatic start of combustion turbine

A gas turbine, automatic starting technology, applied in gas turbine installations, electrical program control, machines/engines, etc., can solve problems such as differences in the characteristic curve of fuel supply at ambient temperature, and achieve the effects of high hardware reliability, easy maintenance, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

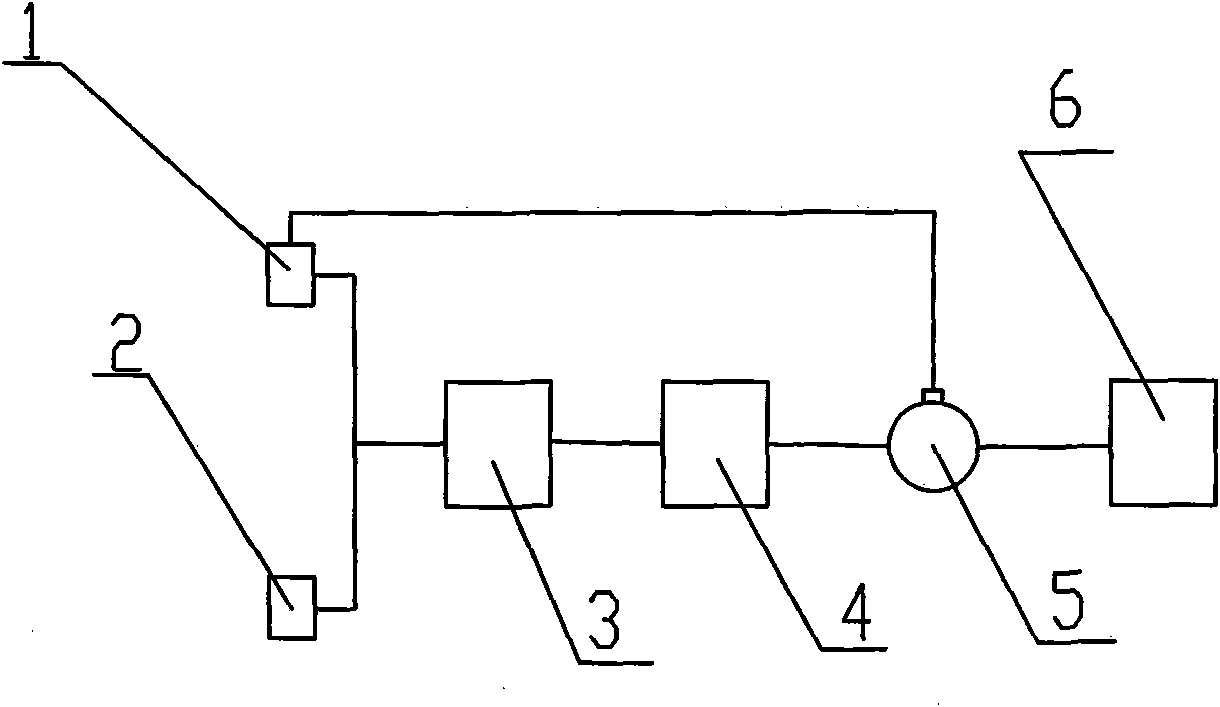

Image

Examples

Embodiment

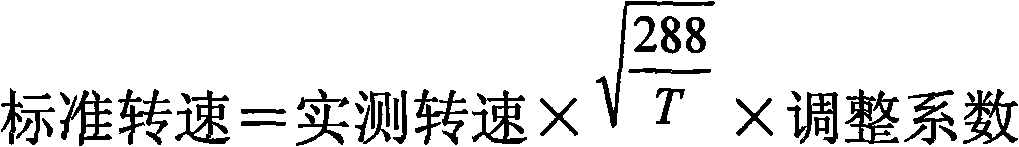

[0024] The speed and the opening amount of the oil supply valve when a certain type of domestic gas turbine generator set is started: the adjustment coefficient is 1:

[0025] Table 2: Comparison table of rotational speed and oil supply valve opening amount at 35°C

[0026] Rotating speed(%)

17

20

25

30

35

40

45

50

55

1100

1000

840

855

875

894

914

933

952

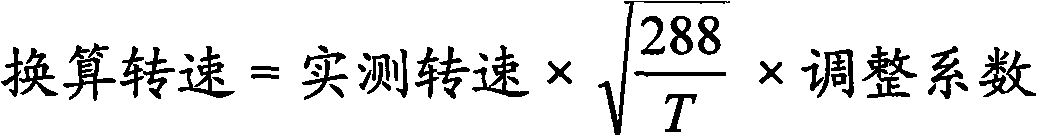

[0027] Table 3: Comparison table of rotational speed and oil supply valve opening at -10°C

[0028] Rotating speed(%)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com