Hydraulic support end head controller communication system

A technology of terminal controller and communication system, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of poor safety, low degree of automation, harsh environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

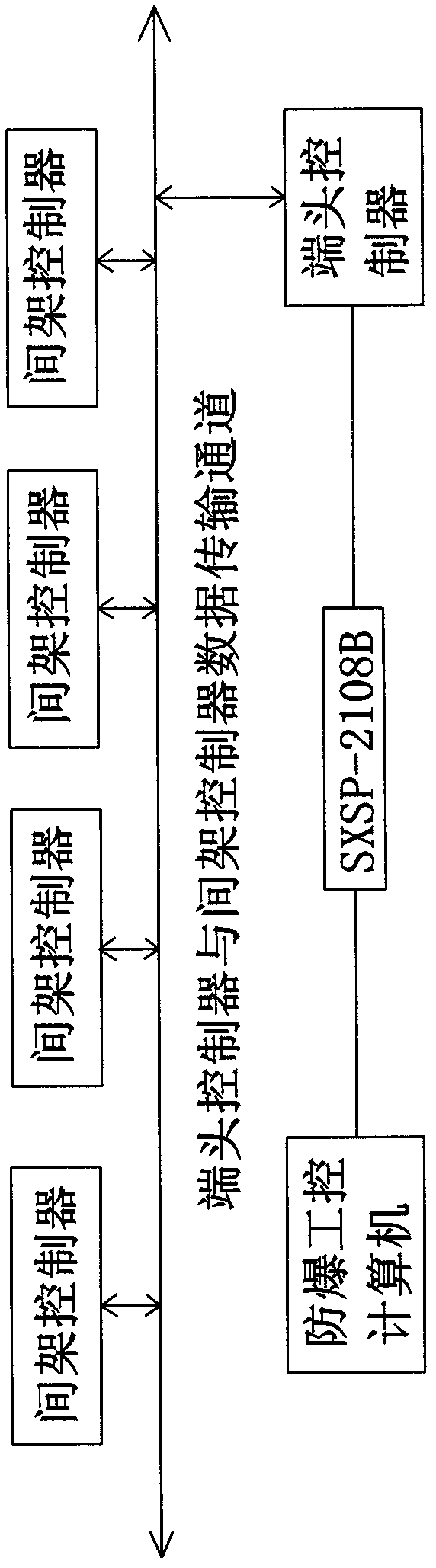

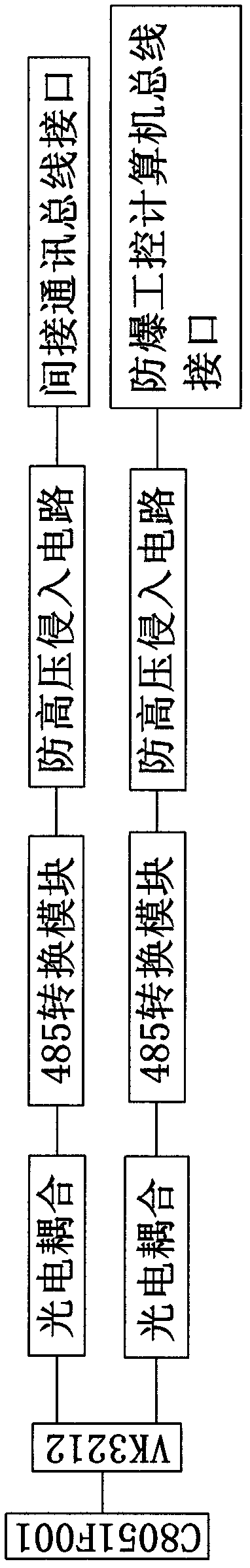

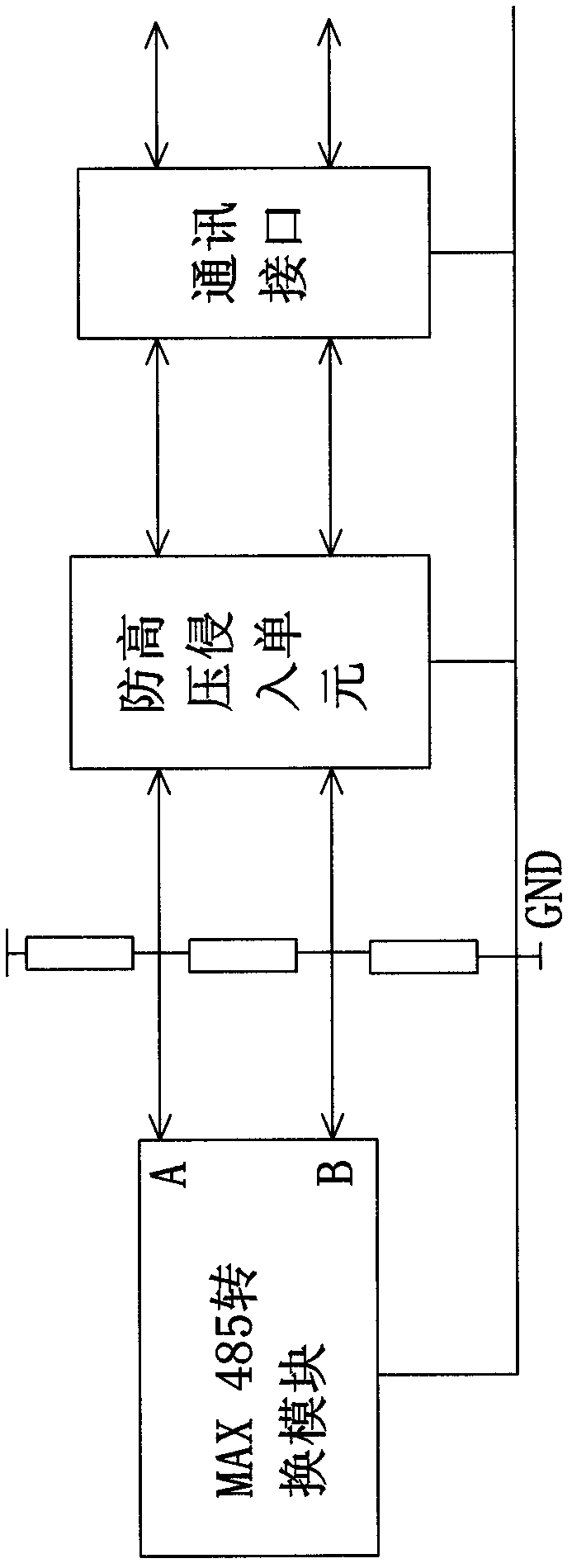

[0021] The schematic diagram of the communication system structure of the terminal controller of the hydraulic support is as follows: figure 1 shown.

[0022] The invention includes a terminal controller, the communication bus of the terminal controller is provided with a frame controller, and the terminal controller is connected with an explosion-proof industrial control computer through an HXSP-2108B converter.

[0023] The terminal controller centrally controls all the inter-rack controllers, and the communication mode adopts the master-slave mode; the default communication mode of the terminal controller is the sending state, and the default communication mode of all inter-rack controllers is the receiving state.

[0024] The rack controller can perform specific actions only after receiving the control signal sent by the end controller. The communication between the terminal controller and the explosion-proof industrial control computer adopts the master-slave mode. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com