Thermal response testing instrument for quickly responding heat transfer performance of buried heat exchangers

A technology for thermal response testing and heat transfer performance, applied in the testing of machines/structural components, instruments, measuring devices, etc., which can solve problems such as uneven temperature distribution of circulating water in the water tank, inability to adjust linearly, and inability to detect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

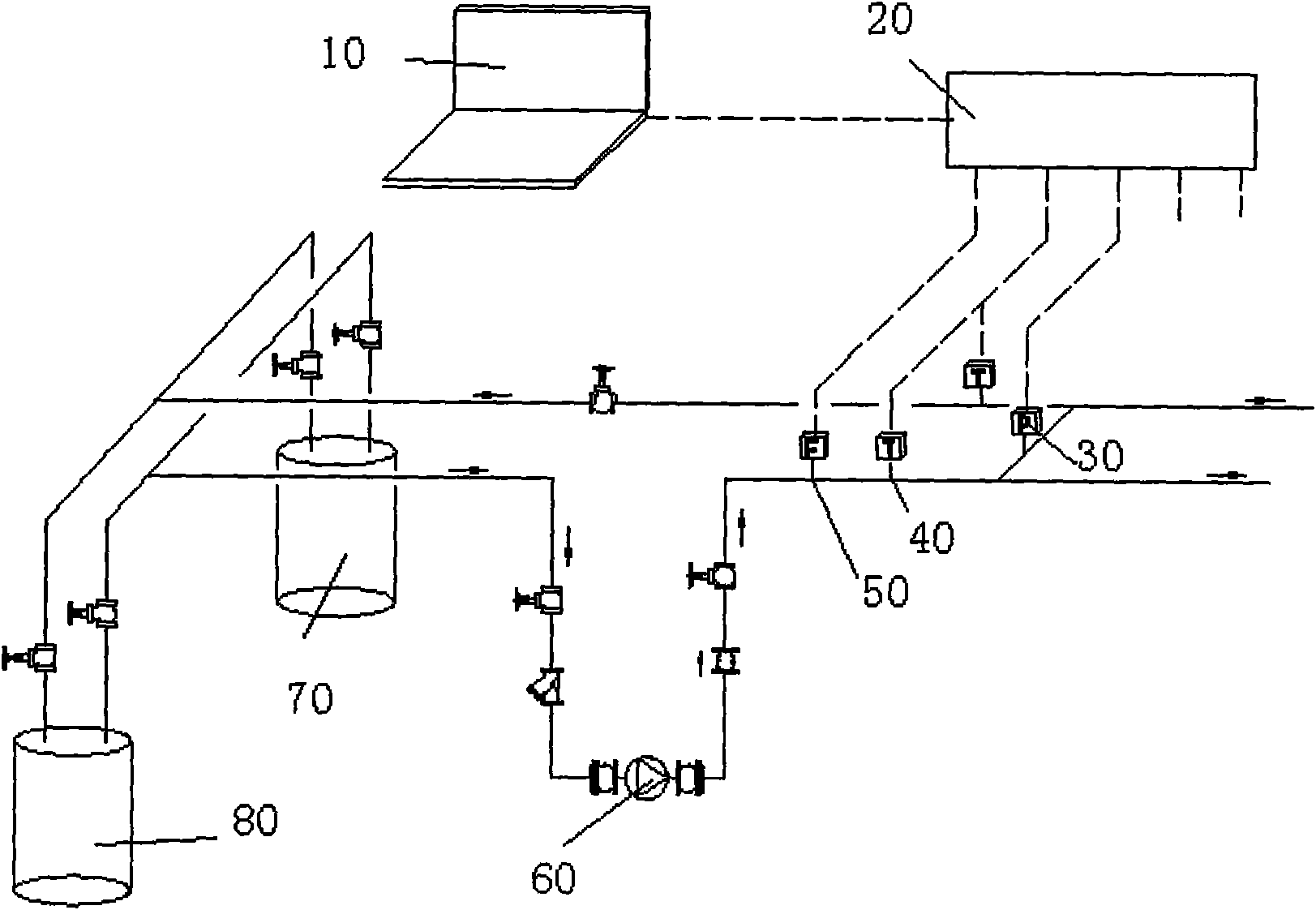

[0018] Depend on figure 2 It can be seen that the present invention includes: an upper machine position 10; said upper machine position 10 is connected with a controller element 20; the controller element 20 is respectively connected with a pressure difference sensor 30, a temperature sensor 40 and a flow sensor 50 through an interface; The difference sensor 30, the temperature sensor 40 and the flow sensor 50 are connected on the pipeline of the system; one end of the circulating water pump 60 is connected with the variable power heat storage bucket 70 or the variable power ice storage bucket 80, and the other end of the circulating water pump 60 is connected with the A buried heat exchanger (not shown in the figure) is connected.

[0019] Variable power heat storage tank 70: The heat storage tank has insulation measures on the outside and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com