Magnetic induction intensity sensing head and magnetic induction intensity measurement method and device thereof

A technology of magnetic induction intensity and sensing head, which is applied in the use of magneto-optical equipment for magnetic field measurement, the size/direction of the magnetic field, etc., can solve the problems of optical fiber temperature sensitivity restricting the development, temperature troubles fiber grating FPI sensor, etc., to achieve high Effects of sensitivity, noise reduction, and measurement accuracy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

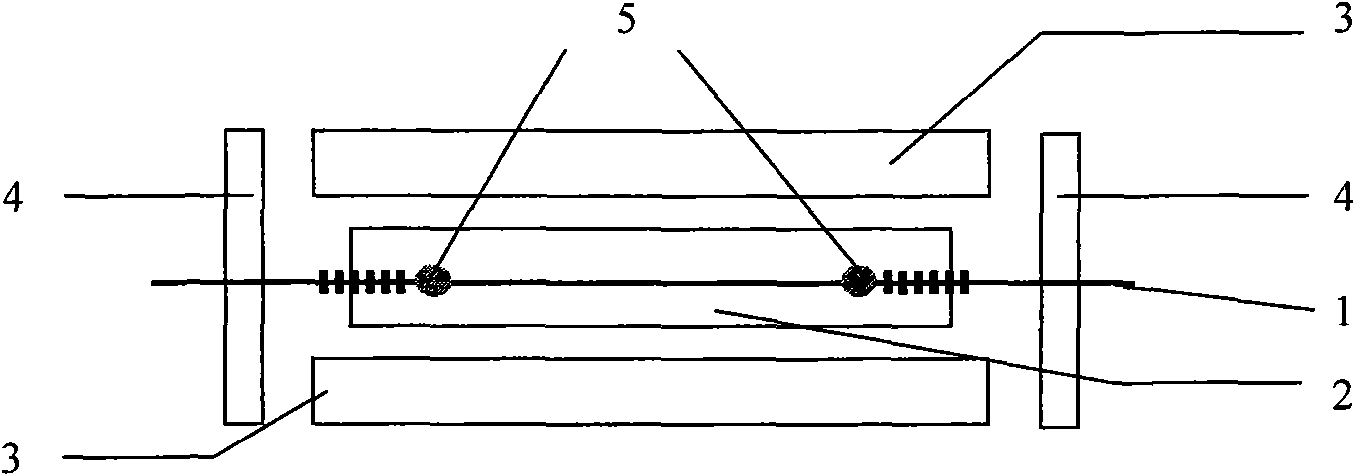

[0023] See attached figure 1 , is the fiber grating FPI magnetic induction intensity sensor probe. The fiber grating F-P cavity is pasted on the magnetostrictive material 2, the permanent magnet 3 is fixed on both sides of the magnetostrictive material 2 in parallel, two sets of coils 4 are placed at both ends of the magnetostrictive material 2, and the high-frequency alternating current is loaded for the measuring device magnetic field.

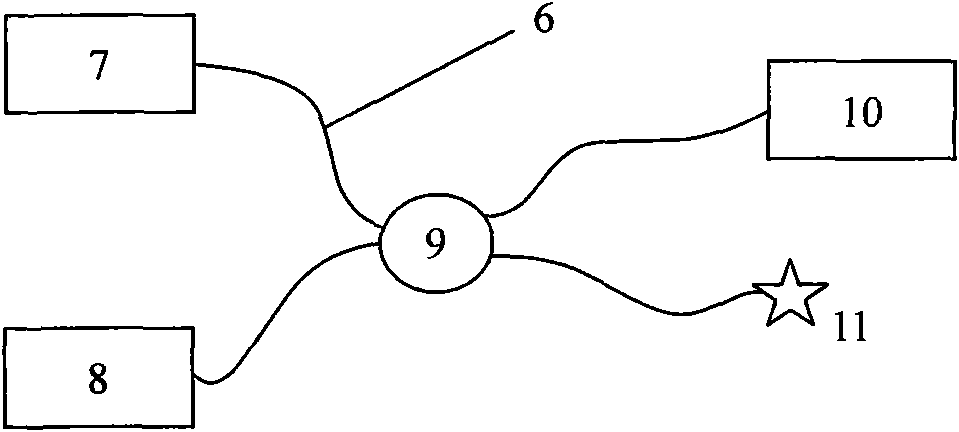

[0024] See attached figure 2 , is a schematic diagram of the structure of the magnetic induction intensity measurement device based on the fiber Bragg grating FPI. attached figure 1 The fiber grating FPI1 of the middle sensor probe is connected to one port on one side of the fiber coupler 9 through the single-mode fiber 6, and the other port is connected to the refractive index matching liquid 11, and the two ports on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com