Method for connecting cable and miniature plug and miniature cable plug thereof

A technology of a small plug and a connection method, applied in the electrical field, can solve problems such as implementation difficulties, and achieve the effects of reducing manufacturing difficulty and manufacturing cost, avoiding core wire stress and cable coming out, and simplifying plug structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

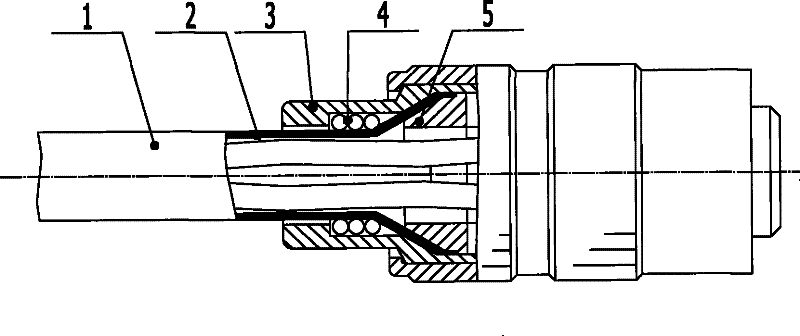

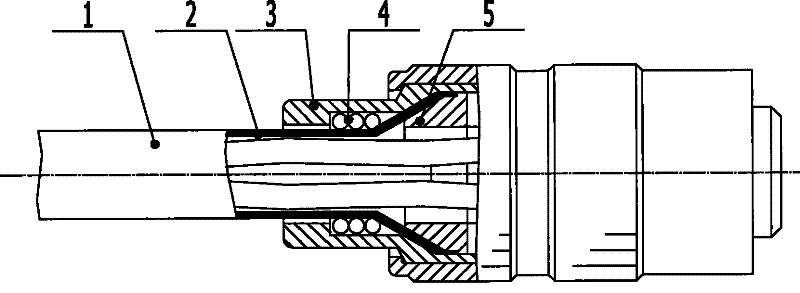

[0008] Such as figure 1 As shown, in the connection method between the cable and the small plug of the present invention, the core wire of the cable is connected to the contact body of the plug, and the shielding layer 2 of the cable is clamped in the conical annular gap between the plug housing 3 and the crimping sleeve 5 A cable bundling cavity is provided between the tail section of the plug housing 3 and the cable 1, the perforation diameter of the cable 1 in the plug housing 3 is smaller than the inner diameter of the bundling cavity, and a stepped structure is formed between the cable perforation and the bundling cavity , The surface of the cable 1 between the root of the tapered structure of the cable shielding layer and the cable penetration is bound with a binding wire 4 and combined with the stepped surface of the plug housing 3 to prevent the cable from coming out.

[0009] The miniature cable plug of the present invention such as figure 1 As shown, between the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com