Controller of wire-cut electric discharge machine and machining path generation device for wire-cut electric discharge machine

A technology of electric discharge wire and cutting machine tools, which is applied in the direction of electric processing equipment, metal processing equipment, circuits, etc., can solve the problems of low processing accuracy and increased processing depth, and achieve the effect of improving processing accuracy, avoiding increase, and avoiding processing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

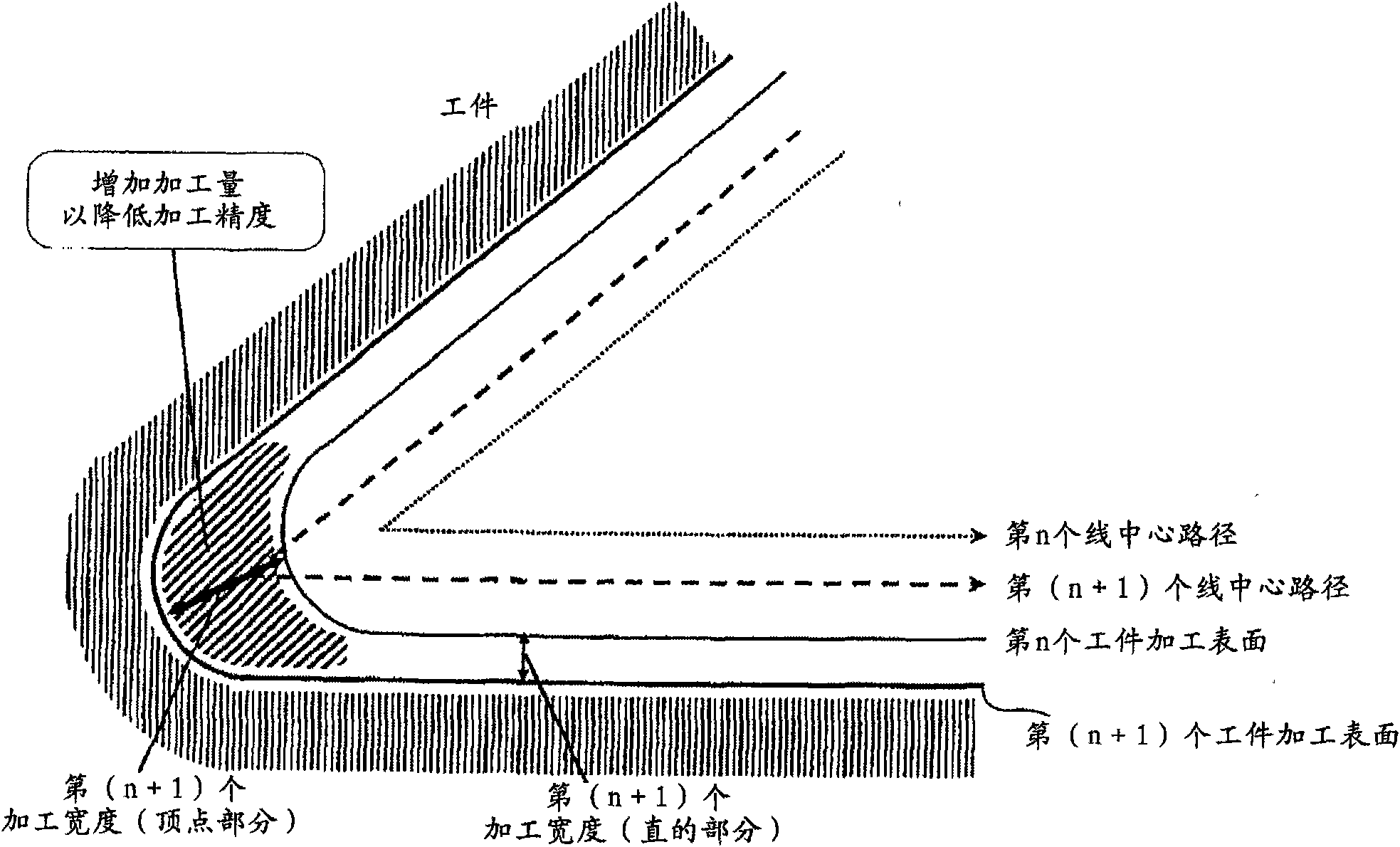

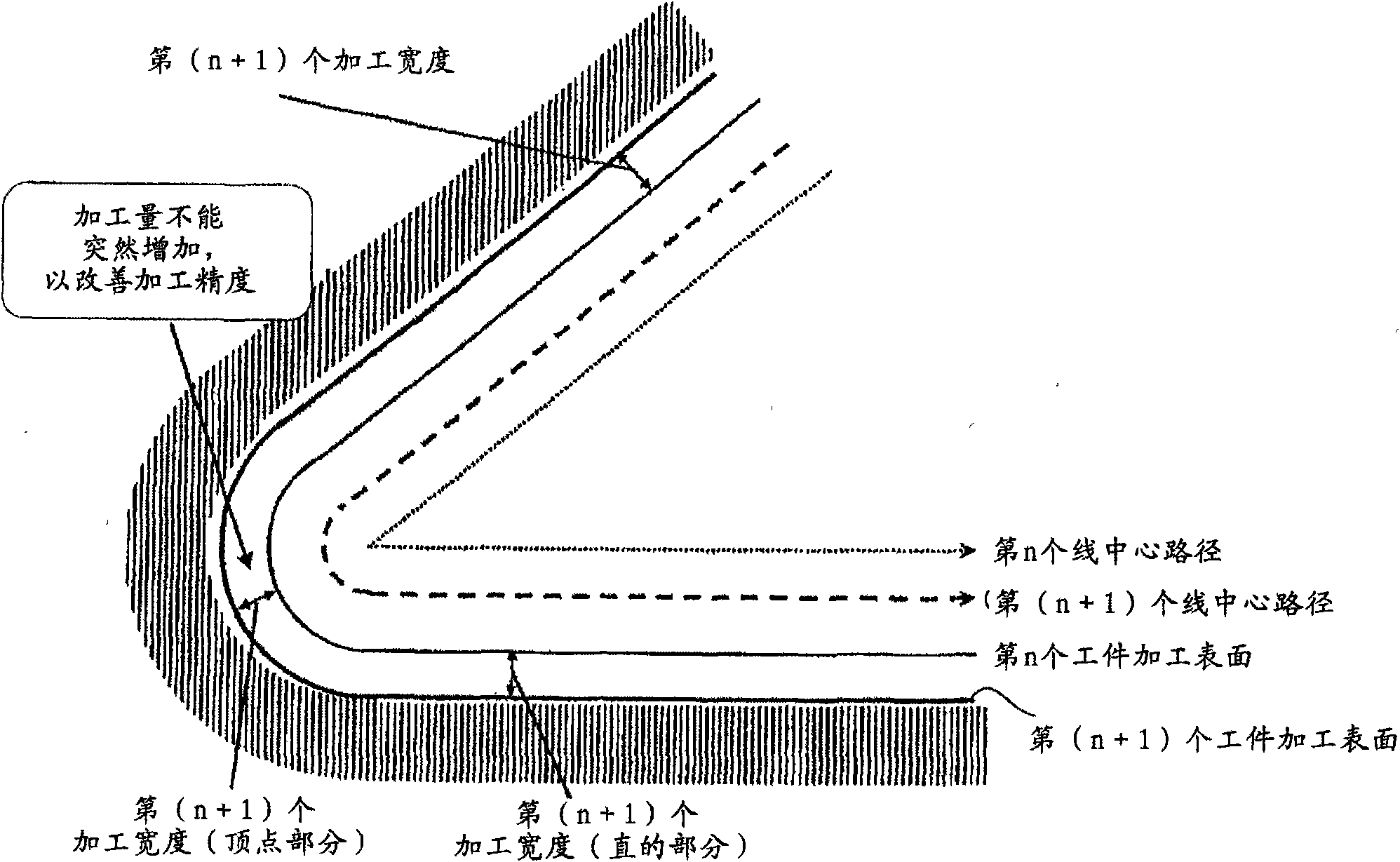

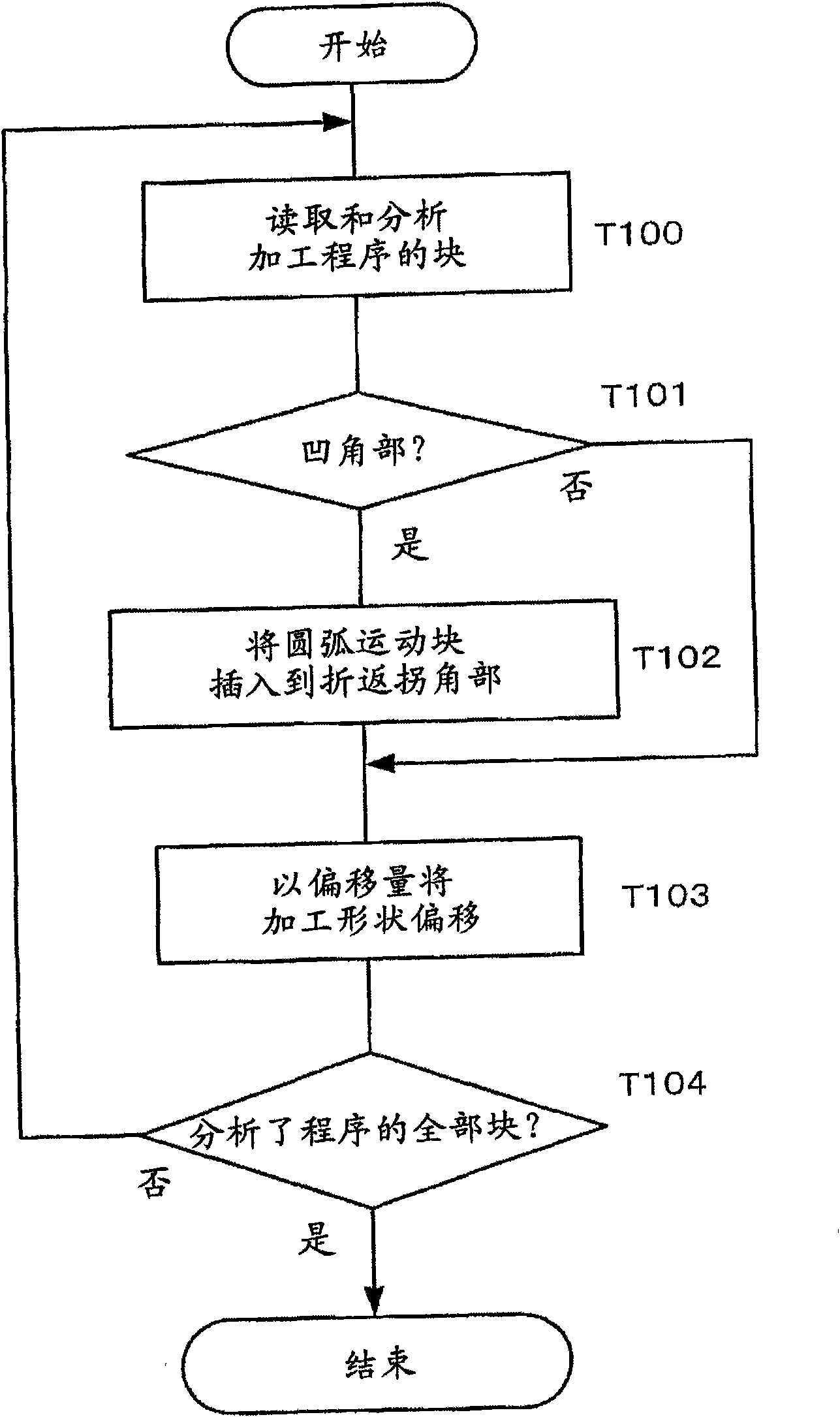

[0064] The present invention is to improve the machining accuracy of the concave corner portion (the concave corner portion formed by two intersecting moving blocks) in the multi-pass machining of finishing. In order to improve machining accuracy, according to the present invention, as figure 2 As shown, based on the processing characteristics of the concave corner in the multi-path processing, the problem is solved by designing and changing the processing path including the insertion of the circular motion block.

[0065] The following will refer to Figure 4 The method of the invention is described. According to this method, the problem is solved by inserting arc blocks into concave corners of the shape commanded by the program. Figure 4 Indicates that the arc block is not inserted into the nth machining operation of multi-path machining but is inserted into the (n+1)th machining operation. In the nth machining operation, the wire electrode moves linearly along the "nth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com