Multifunctional welding piece fixture dedicated to welding training

A multi-functional, fixture technology, applied in the field of tooling and fixtures, can solve the problems of reducing training efficiency, unstable positioning of welding parts, falling off, etc., to achieve the effect of improving training efficiency, convenient and simple clamping, and not easy to swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

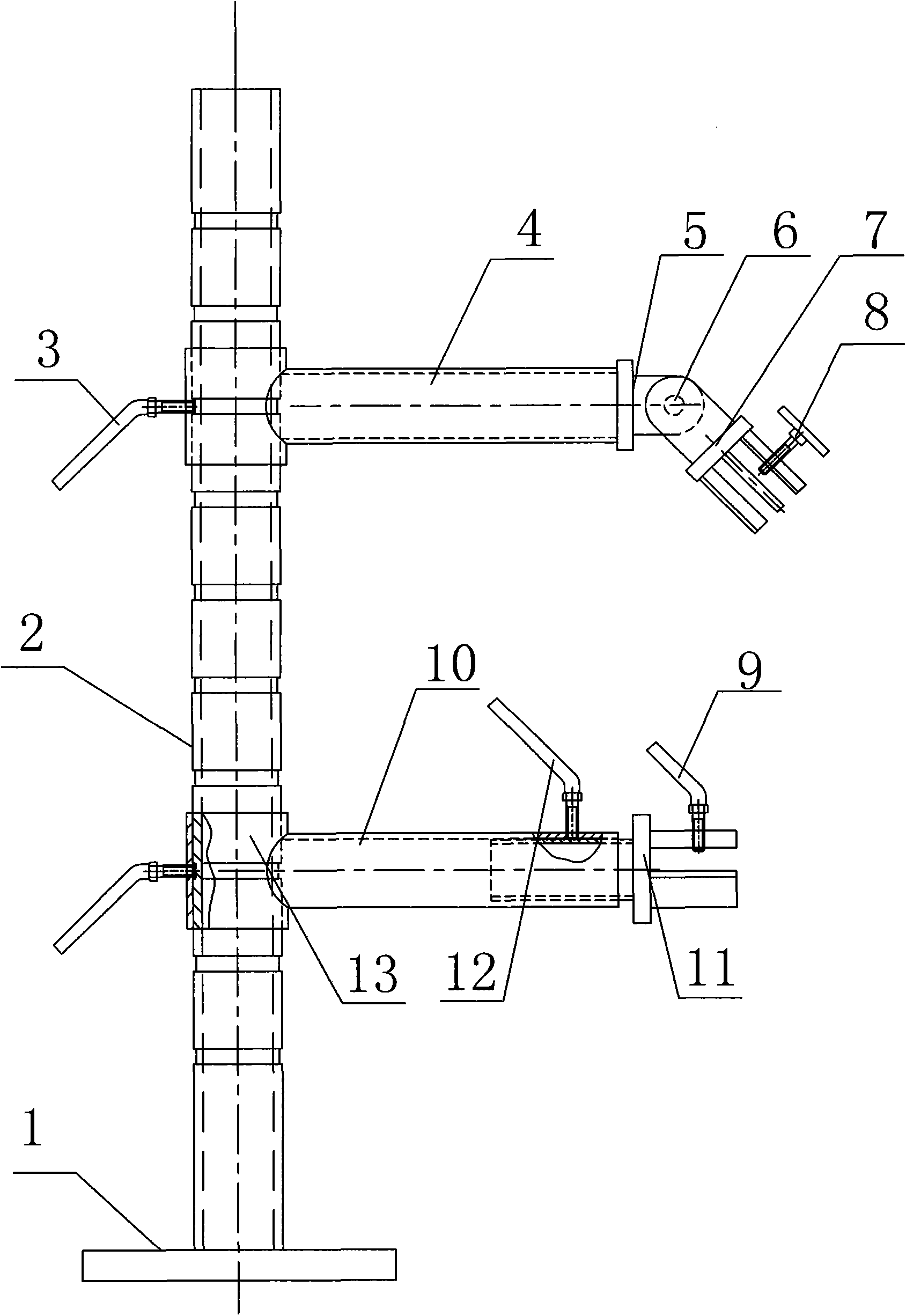

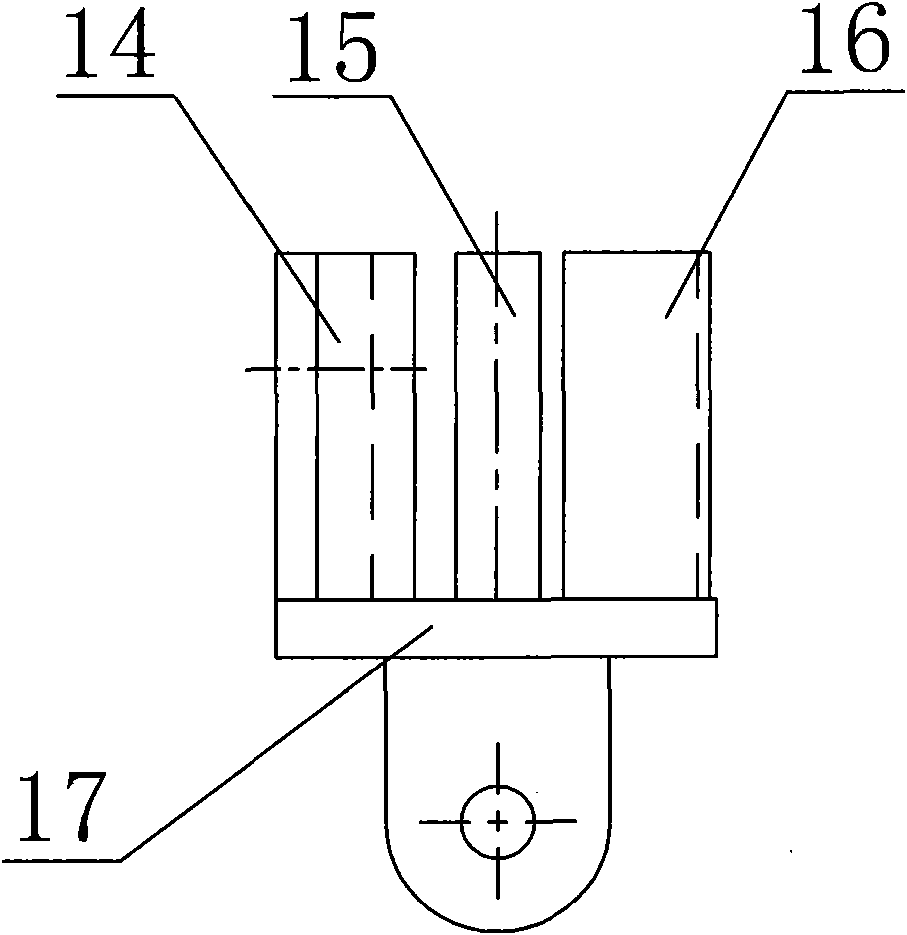

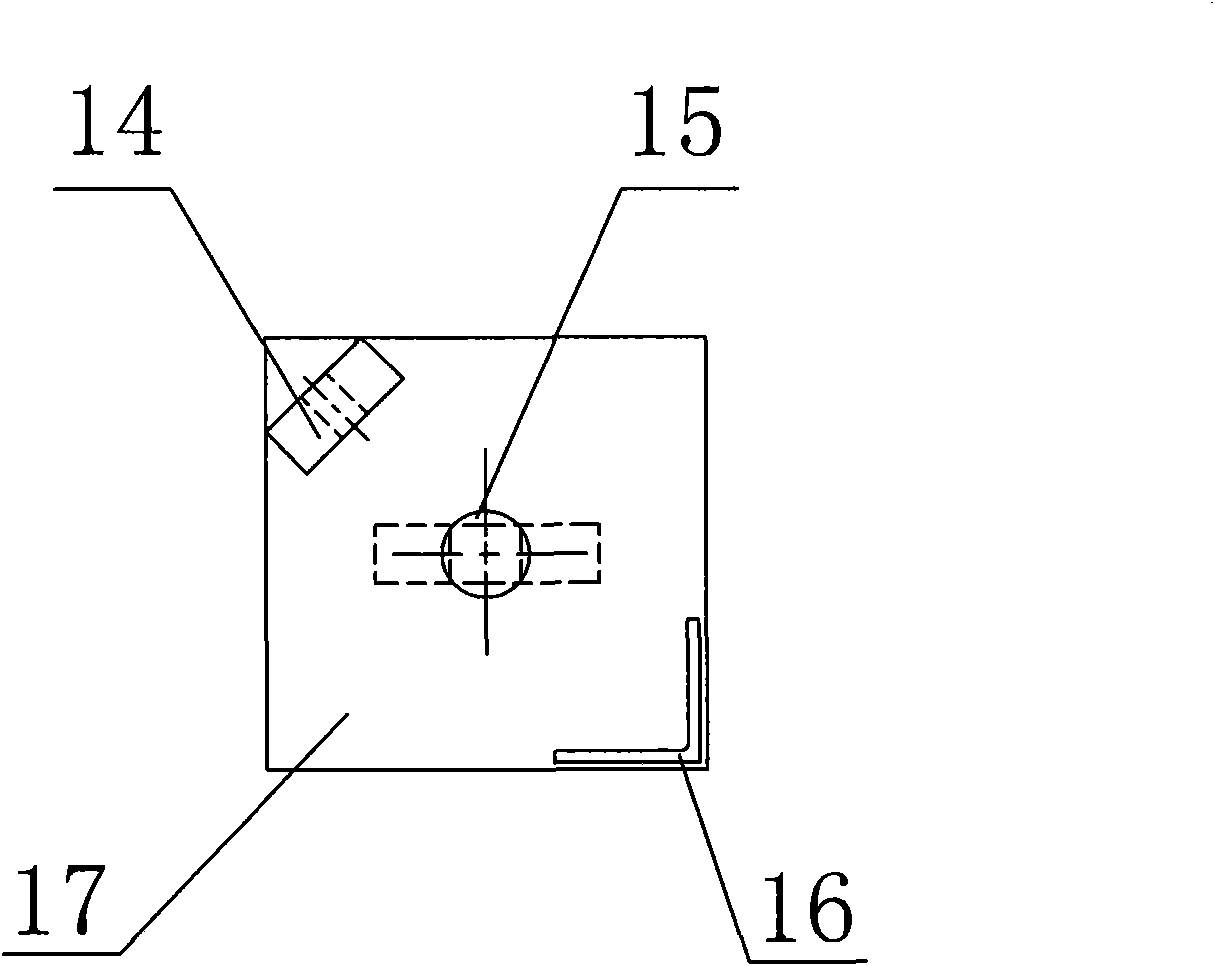

[0019] In order to better understand the present invention, the technical solution of the invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the present invention is not limited to the following embodiments, see Figure 1 to Figure 5 :

[0020] A special multi-functional welding specimen fixture for welding training implemented according to the present invention includes a base 1. Since the base 1 will bear the weight of the entire fixture, in order to maintain stability, the base 1 is fixed on the ground foundation by anchor bolts. The base 1 A column 2 is welded in the center, the column 2 is cylindrical, a cross arm is connected to the column 2, and the end of the cross arm is connected with the clamping part. Since the height of the cross arm on the column 2 is to be adjustable, and it can be rotated 360° around the column 2, so as to adjust the height and angle of the welding test piece, the connection method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com