Resin composition for modifying wood, method for preparing same and application thereof

A resin composition and wood modification technology, applied in wood modification, a composition for wood vacuum pressure impregnation modification and preparation thereof, and the field of compositions for treating wood, which can solve the problem of inconvenient resin curing, Increase environmental problems, reduce wood performance and other problems, to improve physical and mechanical properties, improve dimensional stability, and solve the effects of cracking and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Preparation of resin composition for wood modification

[0041] Take 37% formaldehyde (w / v) 568Kg and add hexamethylenetetramine to adjust the pH to 8.0, heat, add 280Kg urea within 30°C, heat up to 85°C in 30min, keep for 30min; add 377Kg water and add 20% ammonia ( w / v) Adjust pH to 8.3, and cool down to below 40°C for discharging.

[0042] The properties of the resin composition for wood modification prepared in this example are shown in Table 1.

[0043] Table 1 Various properties of resin composition for wood modification

[0044] pH

Solid content / %

Viscosity (coated 4 cups, 25℃) / S

Immersion liquid performance

8.3

38.71

10’60

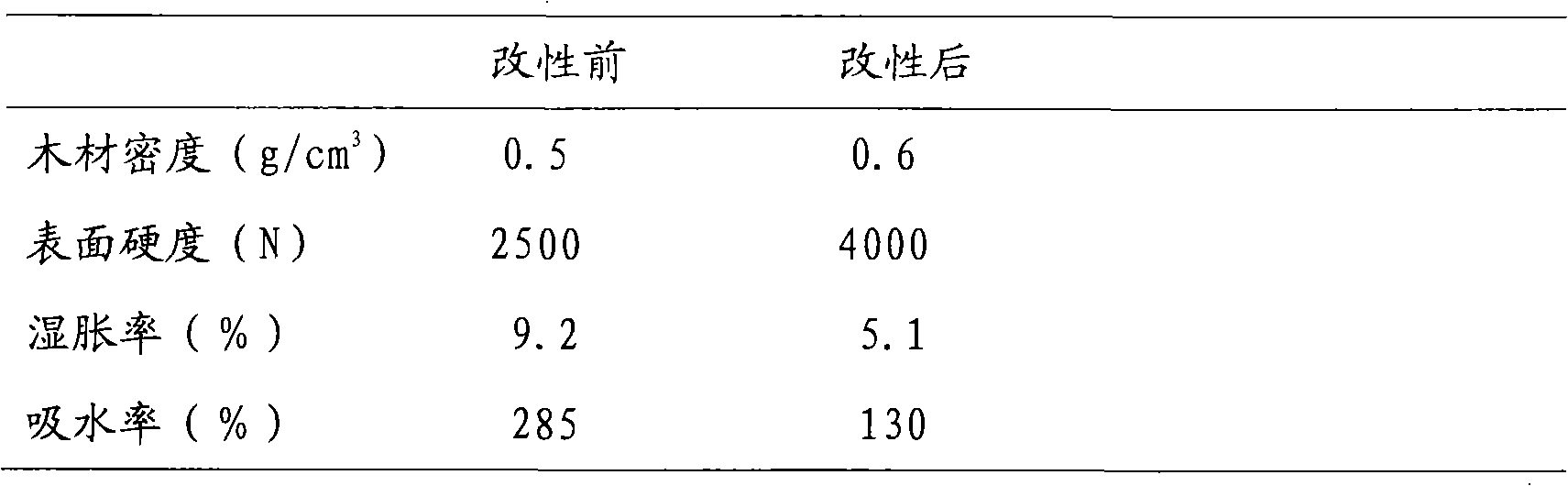

[0045] 2. Application of Resin Composition for Wood Modification

[0046] (1) Put 40L of paulownia wood to be treated into a 110L pressurized impregnation tank and then evacuated, and suck in about 80L under the vacuum condition of -0.09~-0.095MPa. The wood modification prepared in this examp...

Embodiment 2

[0053] 1. Preparation of resin composition for wood modification

[0054] Take 40% acetaldehyde (w / v) 1027Kg and 20% ammonia water (w / v) to adjust the pH to 8.5, heat, add 280Kg of urea within 30℃, heat up to 90℃ for 30min, keep it warm for 40min; add 420Kg of water and add 20 % Ammonia water (w / v) is adjusted to pH 8.5, and the temperature is lowered to below 40°C for discharging.

[0055] The properties of the resin composition for wood modification prepared in this example are shown in Table 3.

[0056] Table 3 Various properties of resin composition for wood modification

[0057] pH

Solid content / %

Viscosity (coated 4 cups, 25℃) / S

Immersion liquid performance

8.5

38.20

11’30

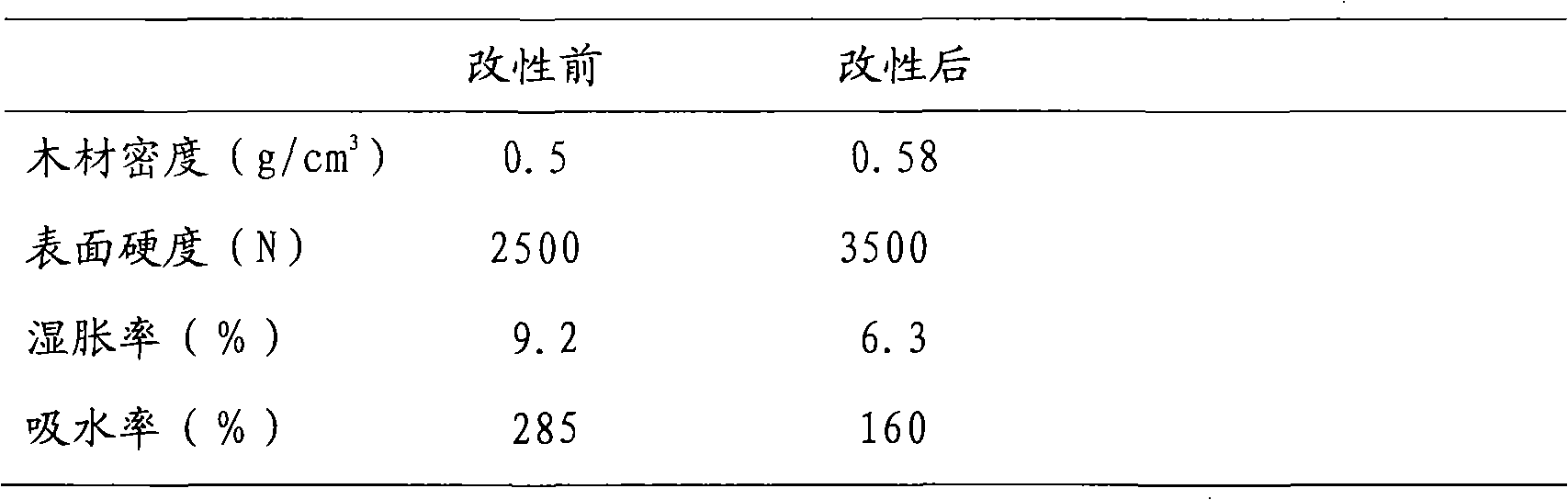

[0058] 2. Application of Resin Composition for Wood Modification

[0059] (1) Put 40L of paulownia wood to be treated into a 110L pressurized impregnation tank and then evacuated, and suck in about 80L under the vacuum condition of -0.09~-0.095MPa. The w...

Embodiment 3

[0066] 1. Preparation of resin composition for wood modification

[0067] Take 37% formaldehyde (w / v) 649Kg and 20% ammonia water (w / v) to adjust the pH to 8.0, heat, add 204Kg of acetyl urea within 30℃, heat up to 90℃ in 40min, keep it warm for 40min; add 257Kg of water and add 20 % Ammonia water (w / v) is adjusted to pH 8.0, and the temperature is lowered to below 40°C for discharging.

[0068] The properties of the resin composition for wood modification prepared in this example are shown in Table 5.

[0069] Table 5 Various properties of resin composition for wood modification

[0070] pH

Solid content / %

Viscosity (coated 4 cups, 25℃) / S

Immersion liquid performance

8.0

37.10

10’40

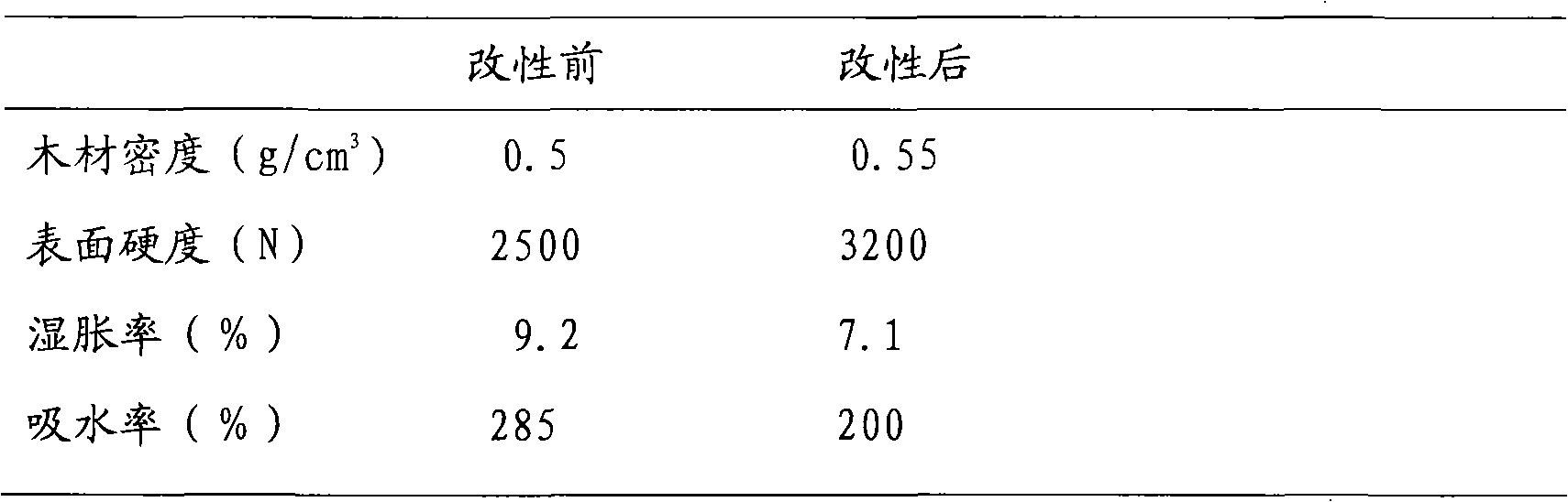

[0071] 2. Application of Resin Composition for Wood Modification

[0072] (1) Put 40L of paulownia wood to be treated into a 110L pressurized impregnation tank and then evacuated, and suck in about 80L under the vacuum condition of -0.09~-0.095MPa. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap