Energy-saving mixed refrigerant

A mixed refrigerant, difluorochloromethane technology, applied in the direction of sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problem of inability to meet the temperature rise requirement of 70°C, high power consumption, failure to meet the requirements, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with specific embodiments.

[0009] A mixed refrigerant of the present invention is composed of the following components in mass percentage: 50-80% of difluorochloromethane and 50-20% of monochlorodifluoroethane.

[0010] The preparation method of the mixed refrigerant is as follows: at normal temperature, chlorodifluoromethane (HCFC-22) and chlorodifluoroethane (HCFC-142b) are physically mixed according to a predetermined mass ratio to form the refrigerant. The specific method is to extract and recover all the HCFC-22 working fluid in the heat pump air-conditioning system, and vacuum the system, and then pour HCFC-22 and HCFC-142b directly into the heat pump air-conditioning system according to the specified ratio.

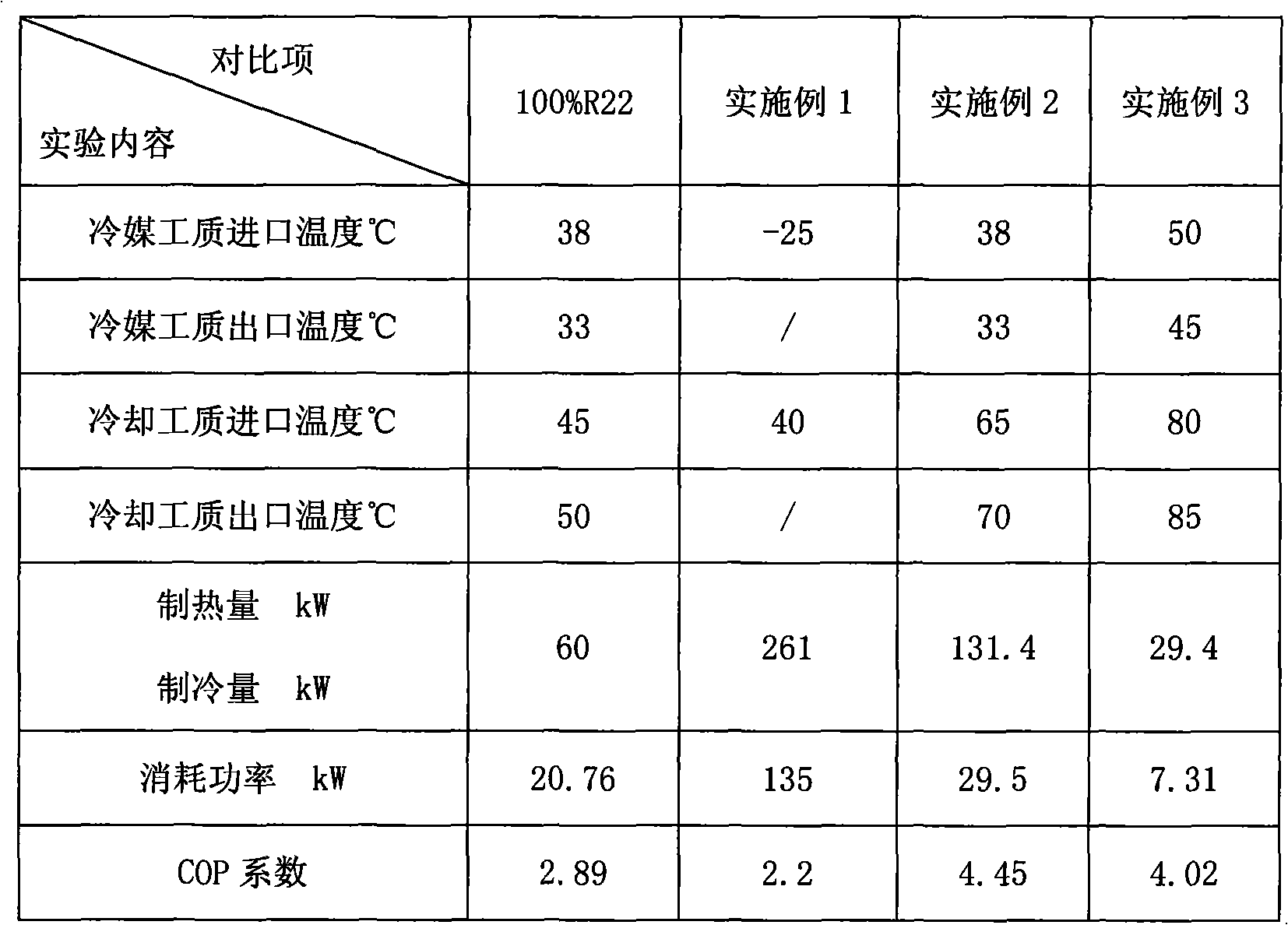

[0011] In order to compare the energy-saving effects of different refrigerants and the degree of impact on the environment, the experimental data of mixed refrigerants (Table 1 below) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com