Butted joint device of underwater oil line

A technology of docking device and oil circuit, which is applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc., to achieve the effects of reducing processing and manufacturing costs, high operating efficiency, and compact structure

Inactive Publication Date: 2010-12-01

HARBIN ENG UNIV

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there is no docking device that meets this requirement at home and abroad.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

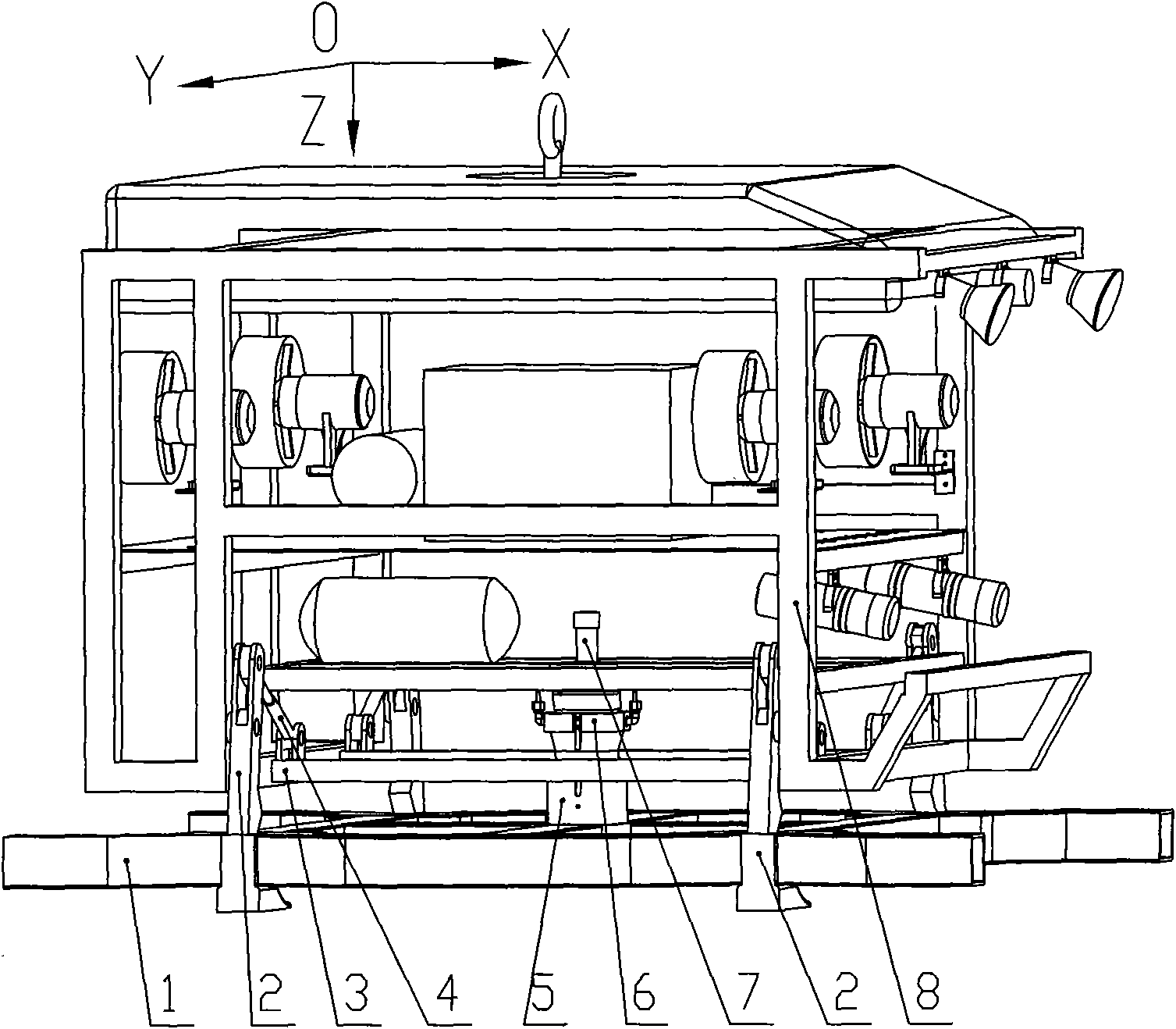

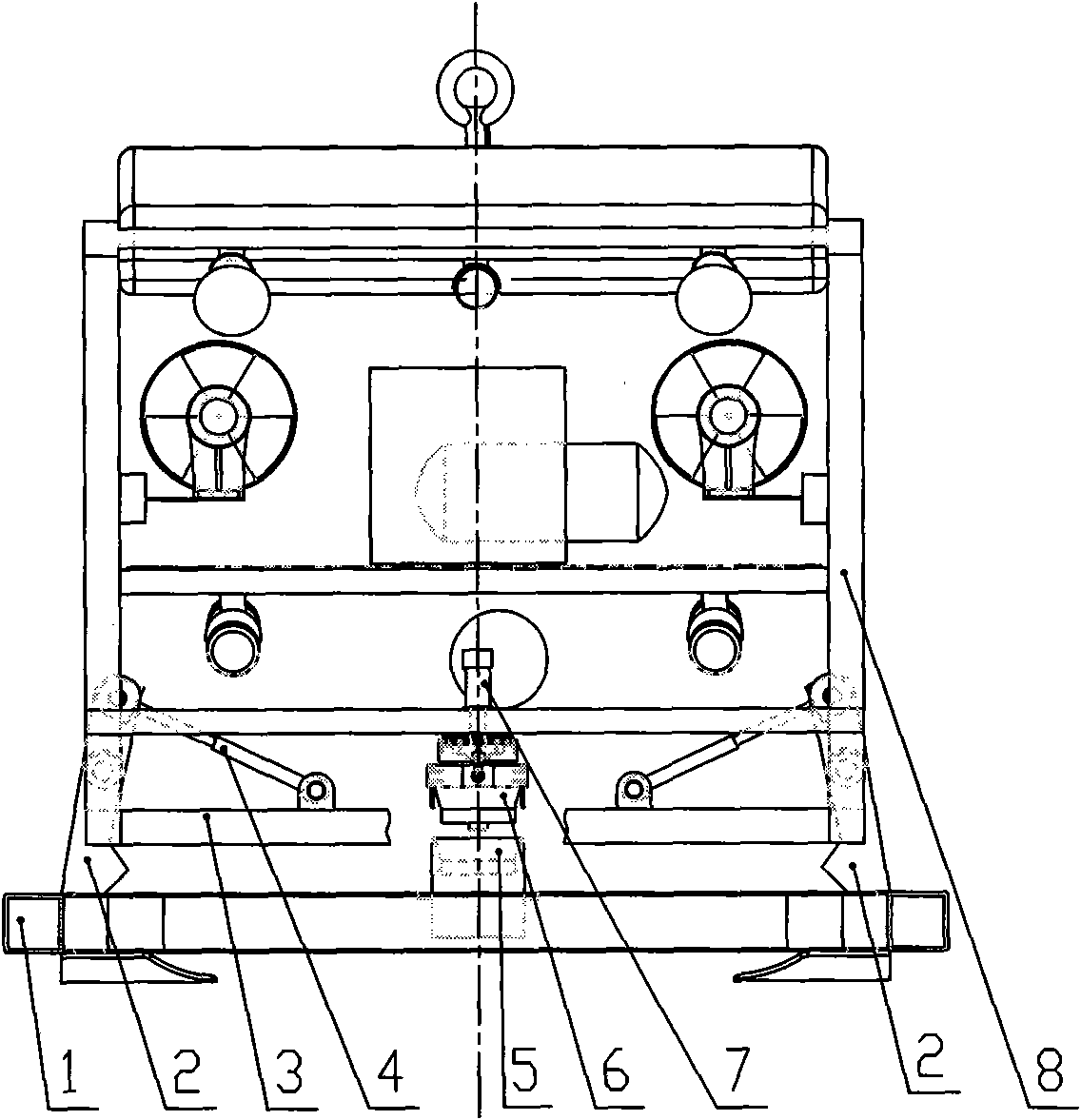

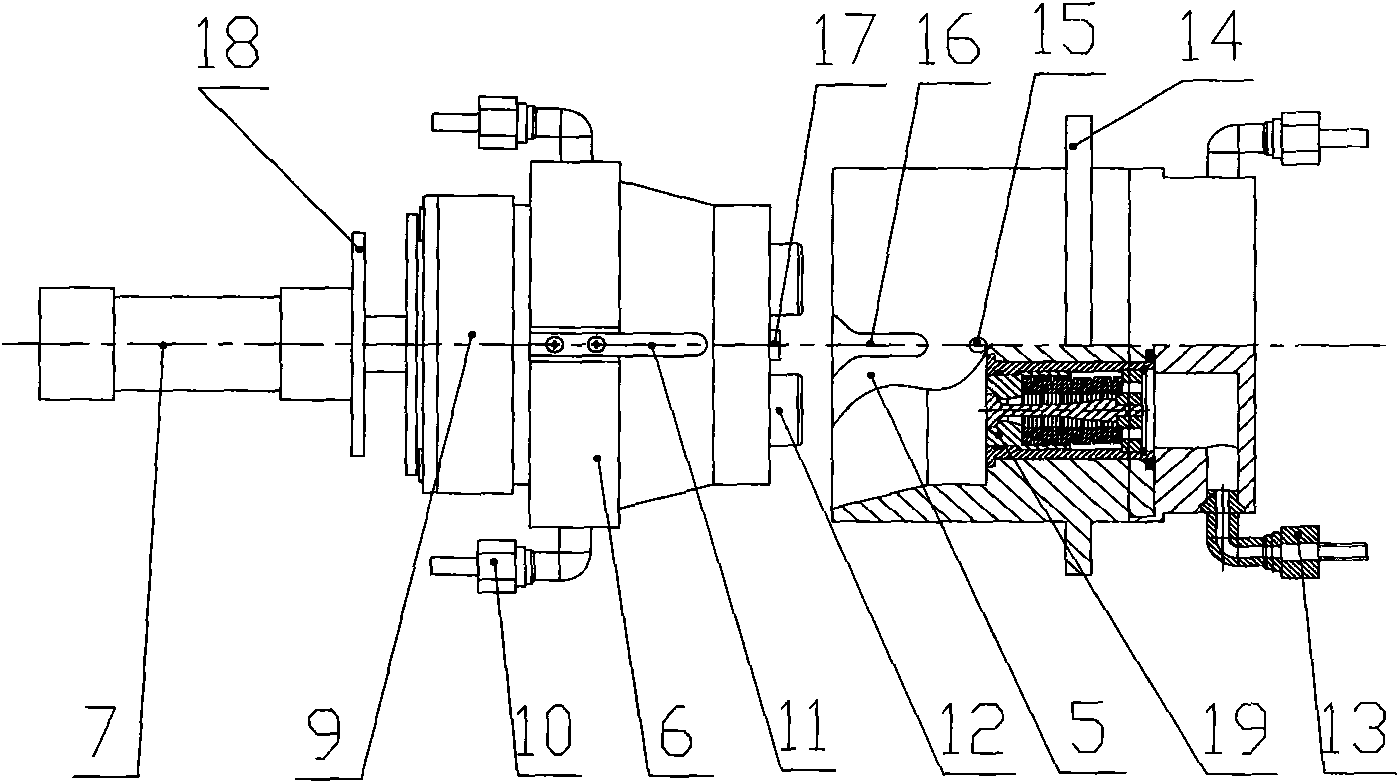

The invention provides a butted joint device for an underwater oil line, which comprises a lower platform, a paw, an upper platform, a paw hydraulic cylinder, a concave hydraulic butted joint, a convex hydraulic butted joint, a convex hydraulic butted joint driving hydraulic cylinder, a sliding platform base, convex oil line plugs, concave oil line plugs and a contact sensor. The upper platform is fixedly connected with an ROV, the paw is articulated with the upper platform, and the lower platform is arranged on the top of an underwater operating machine; the convex hydraulic butted joint is fixedly connected with the upper platform of the butted joint device; and the concave hydraulic butted joint is fixedly connected with the lower platform of the butted joint device. One end of the sliding platform base is fixedly connected with a hydraulic cylinder piston rod, while the other end is fixedly connected with the convex hydraulic batted joint. A pair of the convex oil line plugs is embedded in the convex hydraulic butted joint, and a pair of the concave oil line plugs is embedded in the concave hydraulic butted joint. The contact sensor is fixedly connected with the convex hydraulic butted joint. The butted joint device for the underwater oil line has the advantages of compact structure, high reliability, simple butting process, and high operational efficiency. The butted joint device for the underwater oil line can be applied to underwater operations of the tie-back, the maintenance and the like of deep-sea oil-gas pipelines, and has wide application prospect.

Description

An underwater oil circuit docking device (1) Technical field The invention relates to the technical field of underwater operations, in particular to an underwater oil circuit docking device. (2) Background technology With the continuous depletion of land resources, the development of marine resources has become the main field of world energy development. As one of the untapped treasures and high-tech fields of human beings, the deep sea has become an important strategic goal of various countries, and it is also one of the focuses of fierce international competition in recent years. Due to the limitation of water depth, deep sea underwater operations mainly rely on underwater working tools to complete. In the deep sea environment, the working power of underwater working tools is mainly driven by hydraulic pressure. Due to the constraints of structure and operating conditions, ROVs need to provide hydraulic power sources. The automatic connection between ROV and hydraulic ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16L1/26

Inventor 王立权王才东张岚王文明李明王建秋

Owner HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com