A backlight module

A backlight module and light guide plate technology, applied in optics, light guides, light sources, etc., can solve the problems of reducing the brightness of the surface light source of the backlight module, the loss of incident light energy of the LED light bar, and affecting the display effect of the liquid crystal display, etc., to improve the display effect , Improve the effect of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

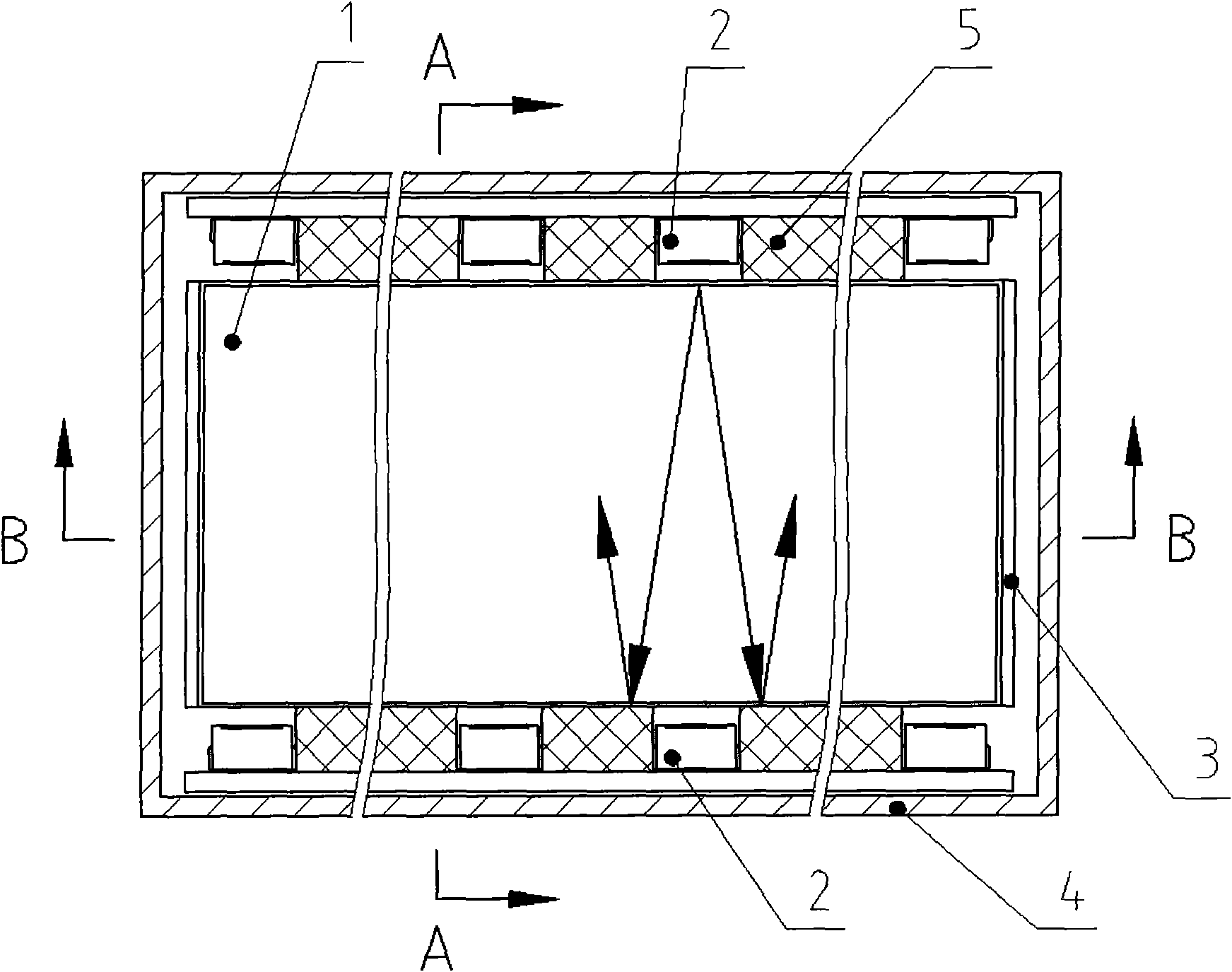

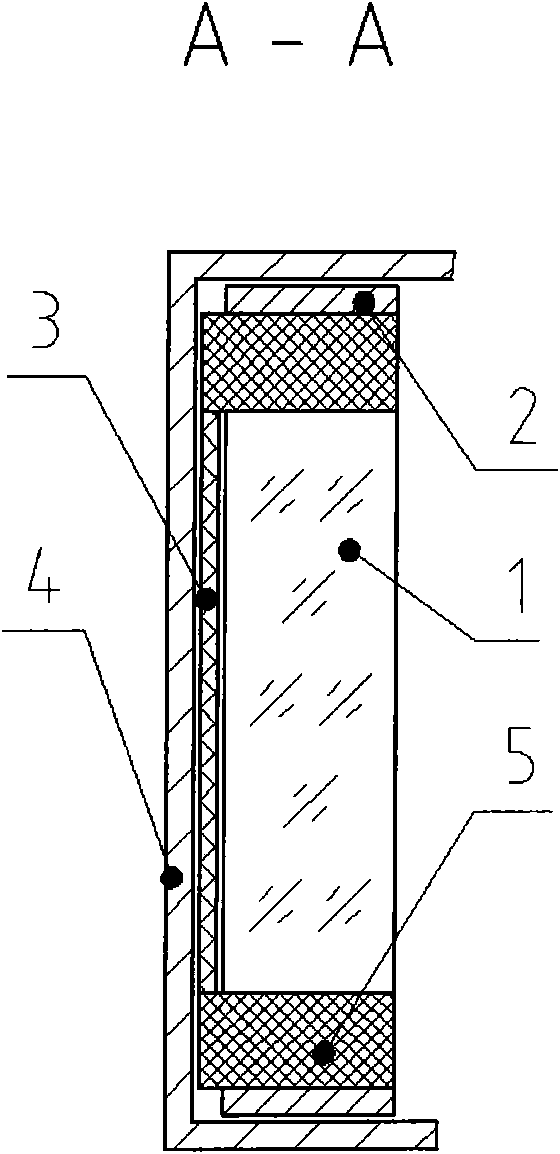

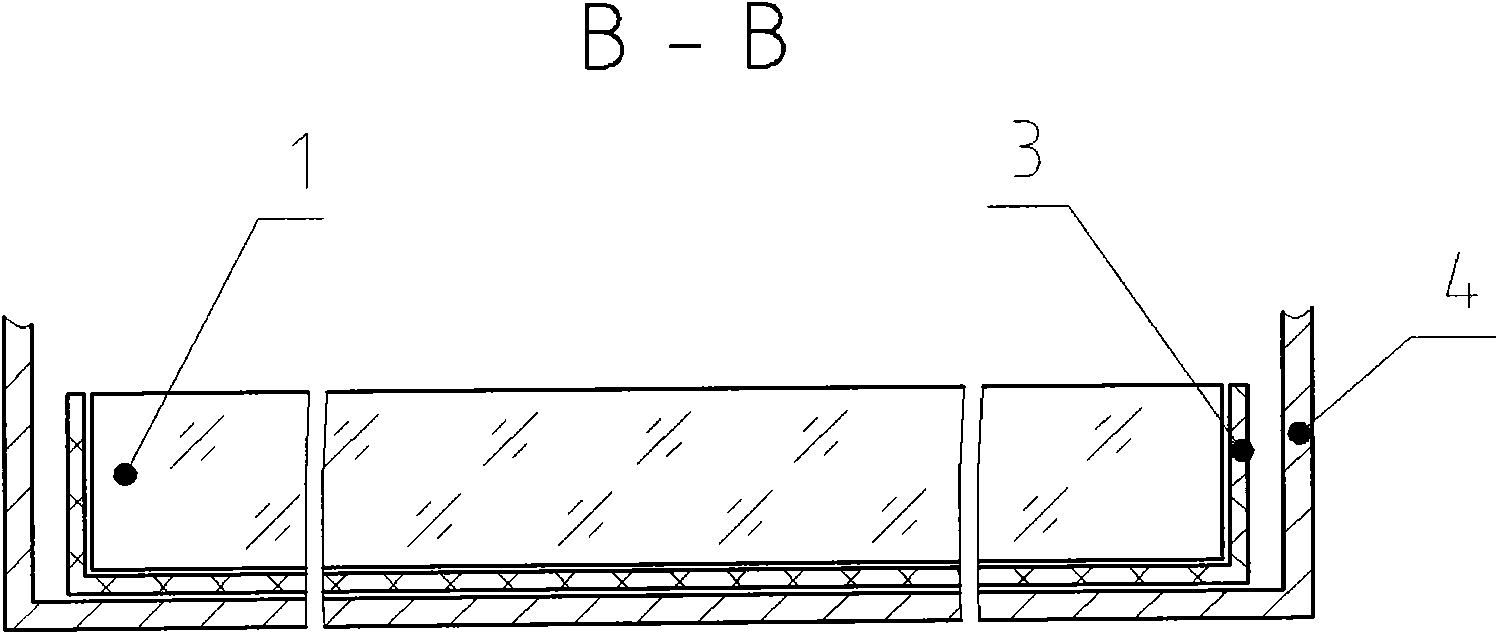

[0012] Such as figure 1 , 2 As shown in , 3 , a backlight module includes a light guide plate 1 , an LED light bar 2 , a reflection sheet 3 and a metal frame 4 . The metal frame 4 is used to clamp and position the light guide plate 1, the LED light bar 2 and the reflector 3; the LED light bar 2 is arranged on the upper and lower sides of the light guide plate 1 to provide the required light source for the liquid crystal display; the reflector 3 is a rectangular structure with two-sided bends, such as Figure 4 As shown, it is arranged on the back surface and the left and right end surfaces of the light guide plate 1, Figure 4 The dotted line in is the bending line of the reflection sheet 3 . A reflective block 5 is set between the LED arrays of the LED light bar 2. The shape of the reflective block 5 is determined according to the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com