Driving method for driving color liquid crystal display device by field order

A liquid crystal display device, field sequential driving technology, applied in static indicators, nonlinear optics, instruments, etc., can solve the problems of single color liquid crystal display device, monotonous color of color liquid crystal display device, etc., and achieve rich colors and control circuits. Simplified, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

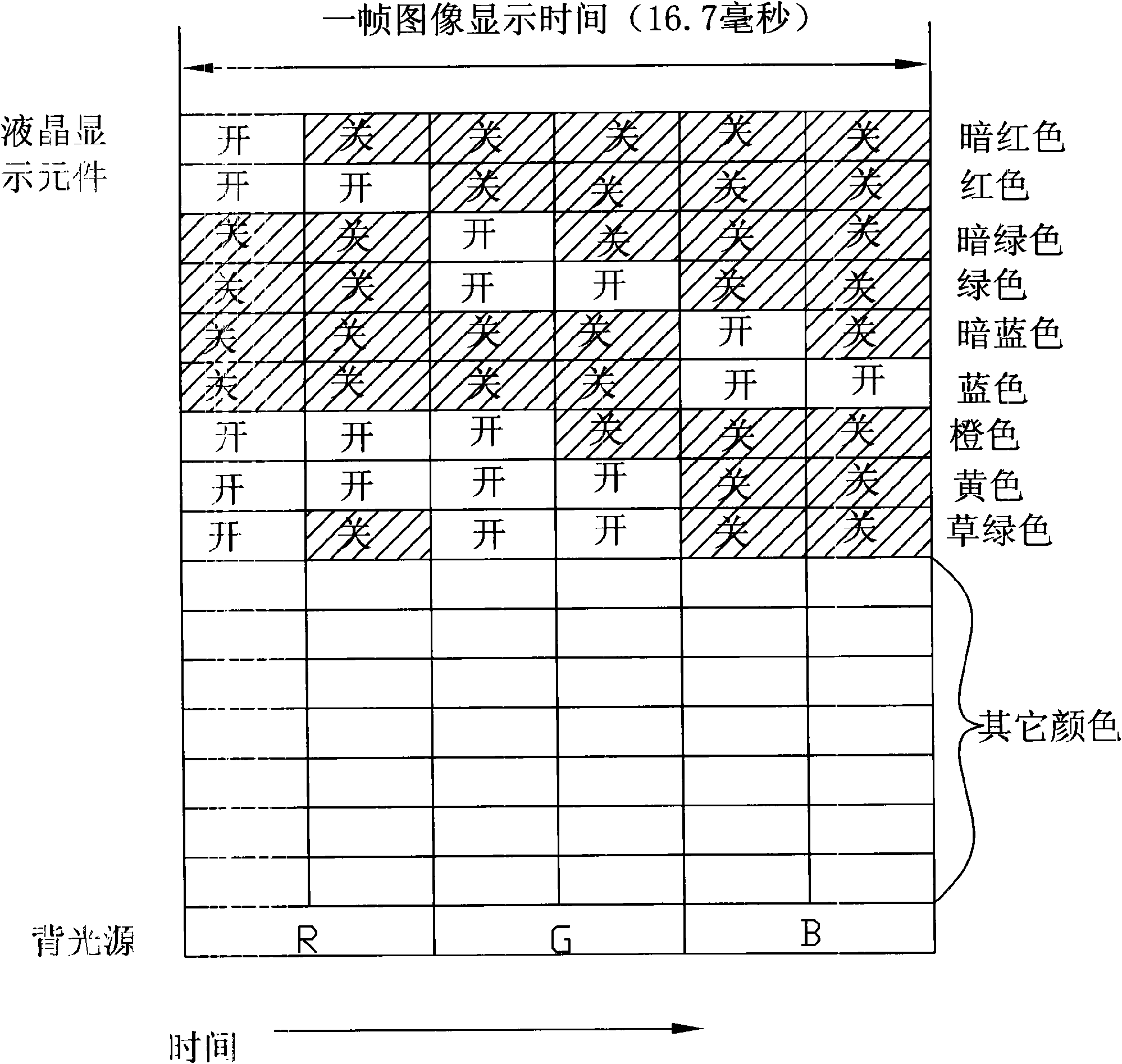

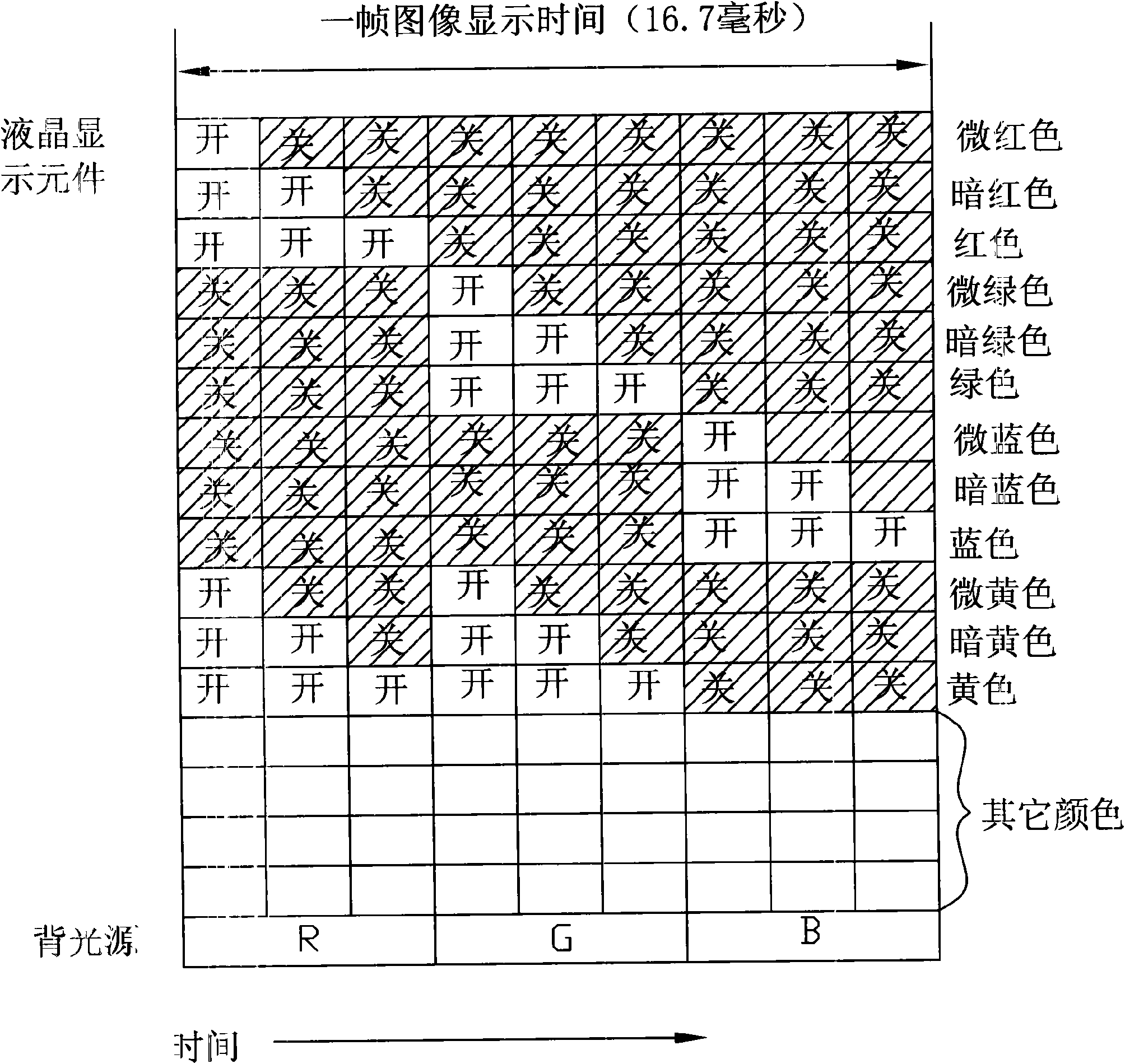

[0019] The core of the driving method of the field sequentially driven color liquid crystal display device is: without changing the driving frequency of the backlight source of the field sequentially driven color liquid crystal display device, in each color region of monochrome display, change the frequency of the liquid crystal display element The driving frequency is to change the switching times of the liquid crystal display element so that it switches twice or more in a single-color display color zone.

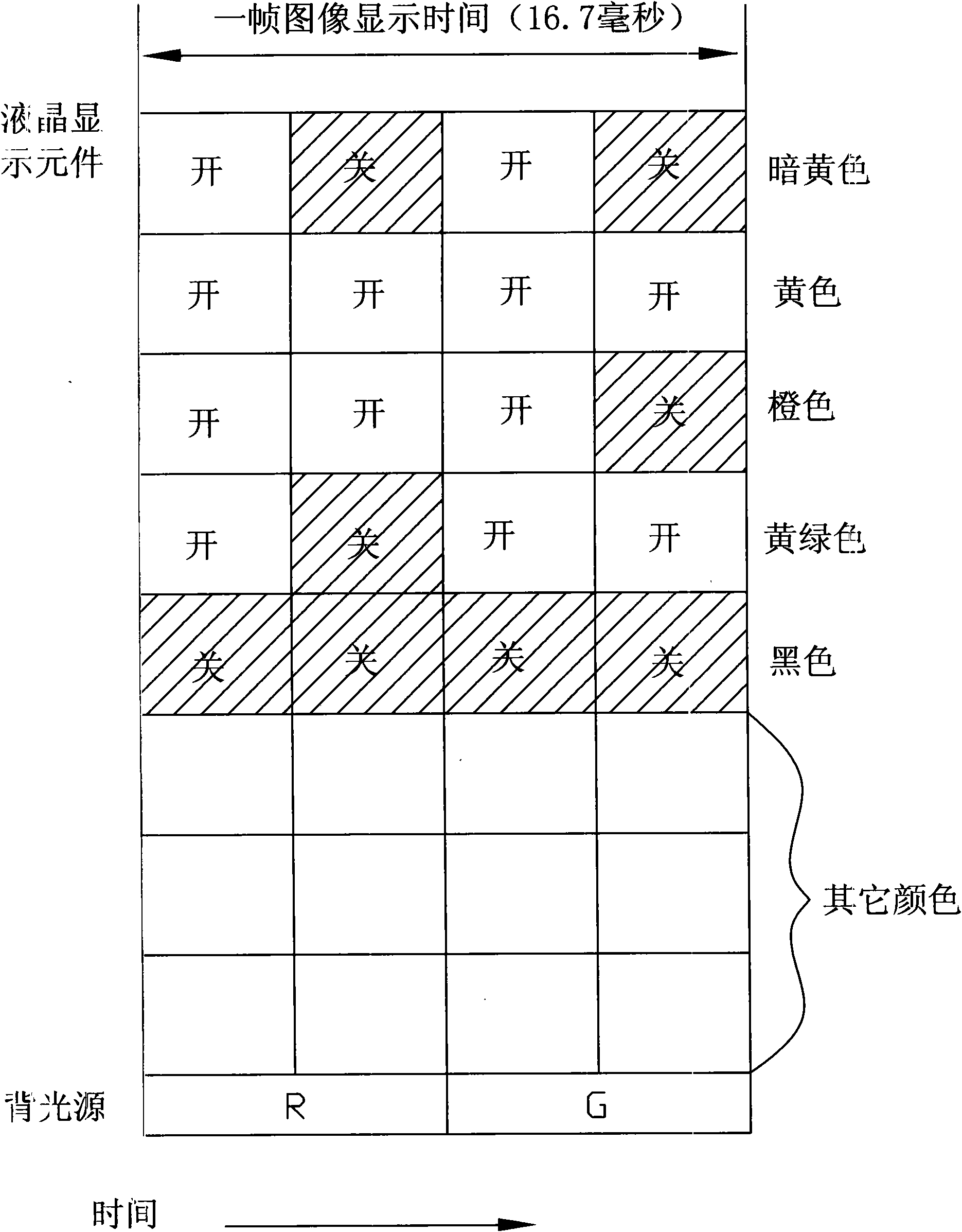

[0020] See figure 1 , figure 1 It is a schematic diagram of driving a backlight source for two groups of colors in the present invention. As shown in the figure, when the backlight is two groups of colors, the figure shows a group of red (R) and a group of green (G) (LED lights of corresponding colors can be used), by changing the on or off of the liquid crystal display element The number of times off can achieve the purpose of rich colors, such as figure 1 In the fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap