Easily-opened aluminum plastic composite packing hose and manufacturing method thereof

An aluminum-plastic composite, easy-to-open technology, applied in the field of daily necessities, can solve problems such as affecting health and safety, thimble contacting toothpaste or medicine, food, easy to be contaminated, etc., to avoid pollution, to open quickly, and to achieve the effect of simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

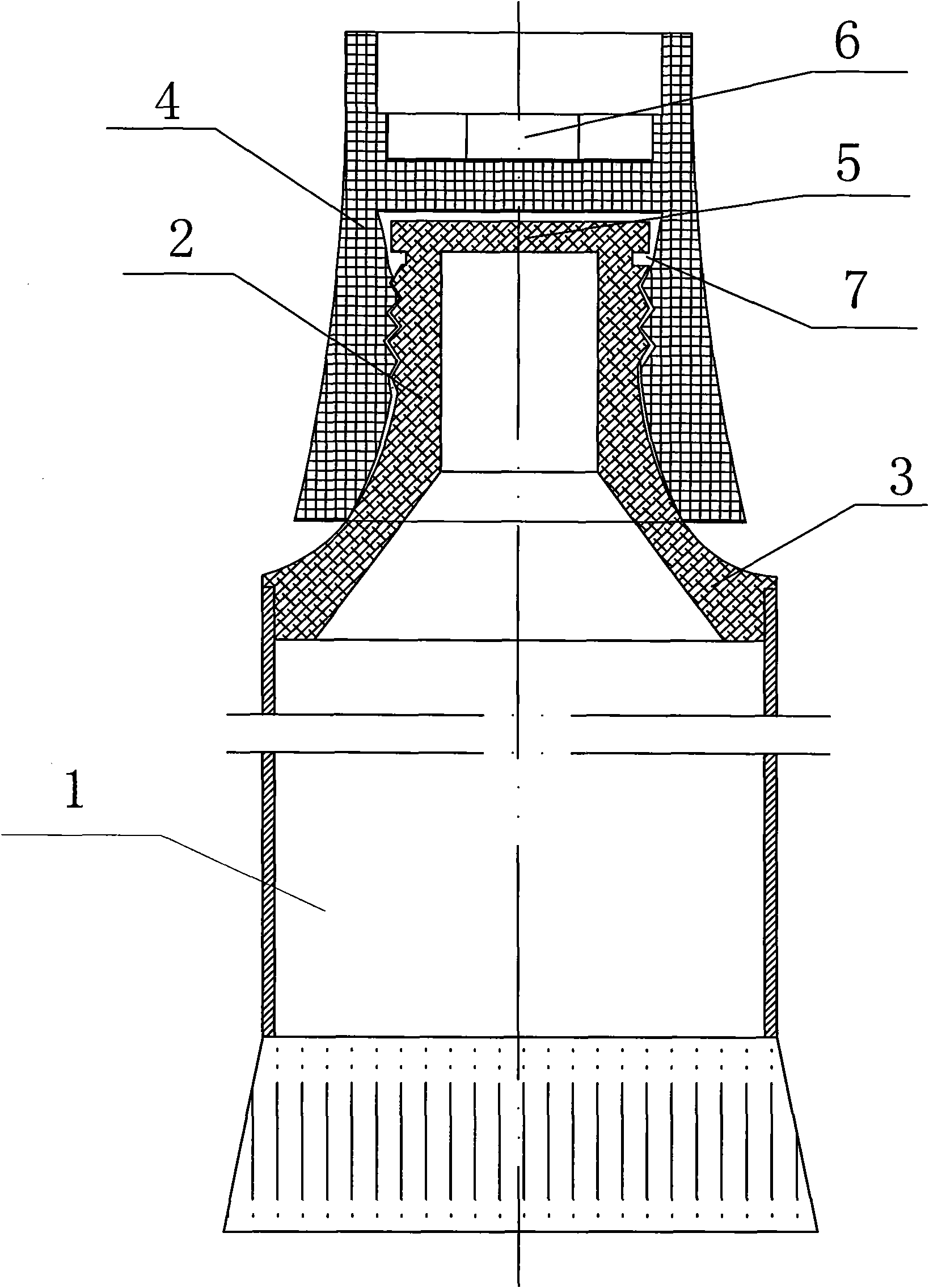

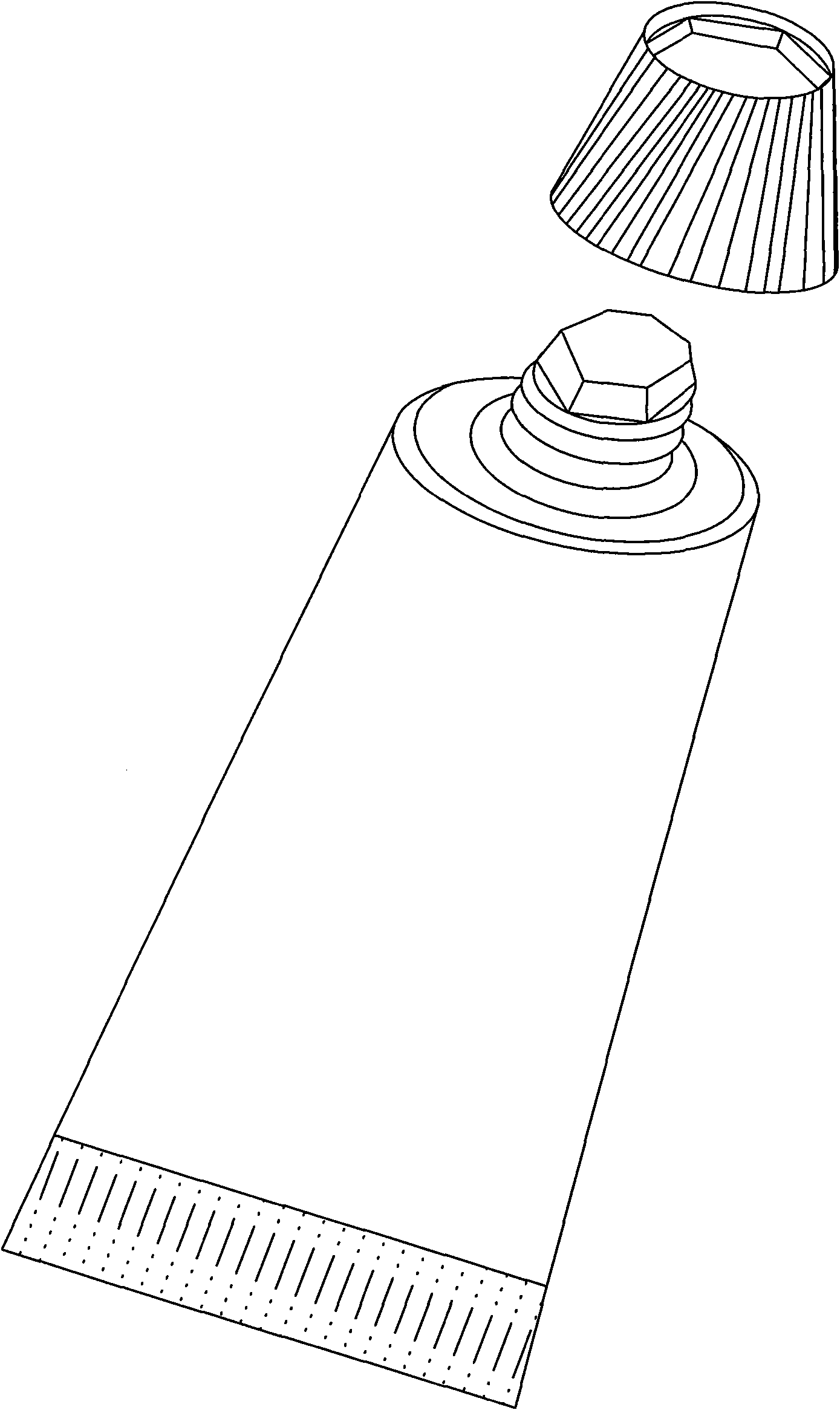

[0016] 1. The pipe body is made of aluminum-plastic composite sheet. First, the aluminum-plastic composite sheet is sterilized with ultraviolet light, and then heated by a high-speed pipe making machine at high frequency and welded to grow the pipe;

[0017] 2. The long tube is pulled by the synchronous motor on the traction belt. At the same time, the photoelectric sensor is used to send a signal according to the color mark on the sheet. Under the command of PV, the rotary knife is driven by the servo motor to rotate and cut into Short tubes.

[0018] 3. On the hydraulic paste injection machine, the worker inserts a short pipe, the pipe is 1.00mm to 1.5mm higher than the mandrel step, mixes it with 40% low density and 60% high density polyethylene, and heats it in the cylinder of the hydraulic paste injection machine To the upper part of 230 ° C, the lower end of about 250 ° C, inject 4kg ~ 6kg with an appropriate pressure, keep the pressure at 1.5kg ~ 2.5kg, push it on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com