Air and gas double heat accumulating type burner

A gas heat storage and burner technology, which is applied in the fields of fuel combustion and combustion devices in industrial furnaces, can solve the problem that the gas and gas heat storage chambers are located in the same metal cavity lined with refractory materials, and achieve technical The effect is remarkable, the connection is tight, and the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

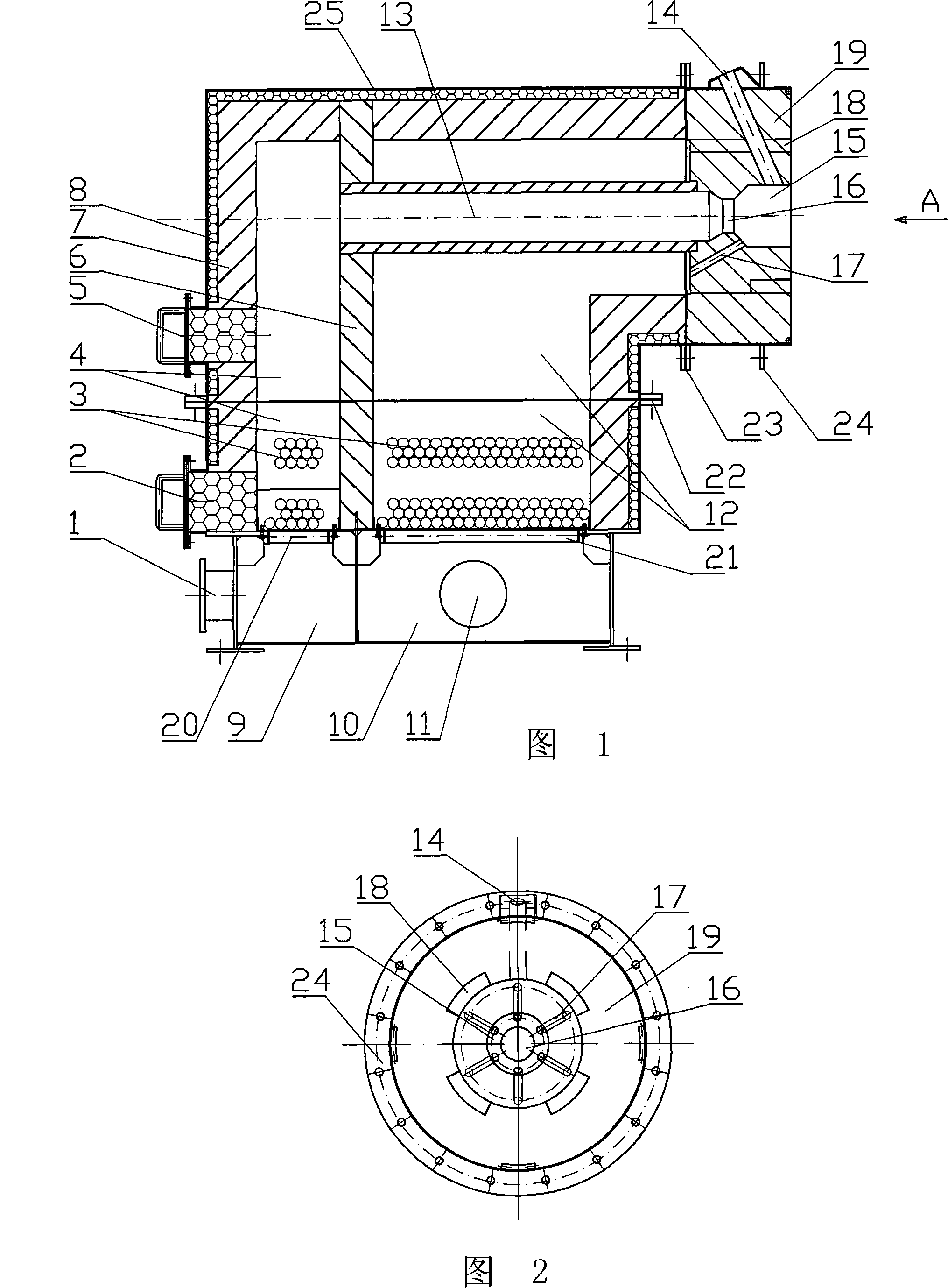

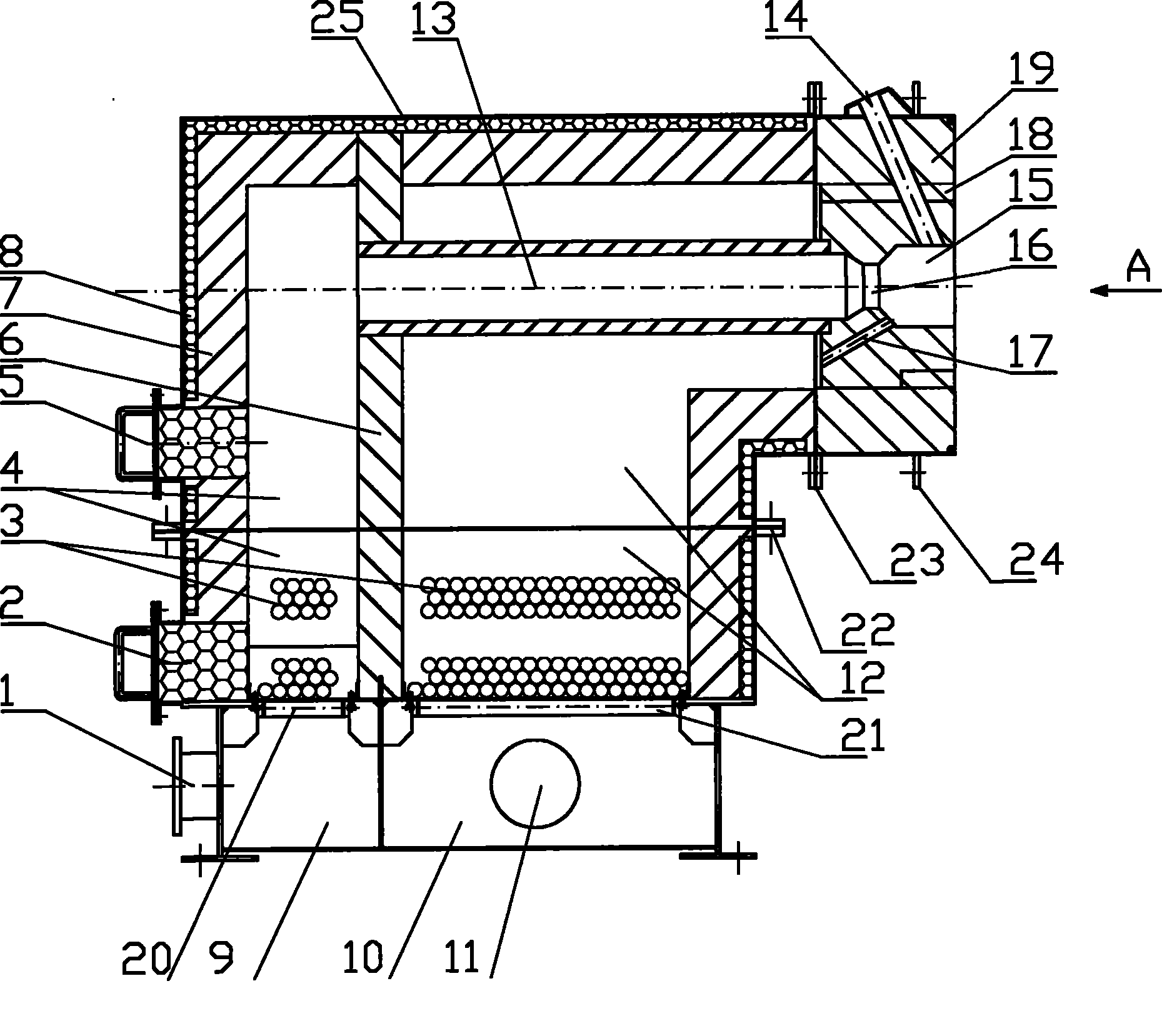

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. as attached figure 1 , 2 As shown, the lower part of the dual regenerative burner of the present invention is a gas collection chamber 9 and an air collection chamber 10, and a gas inlet 1 and an air inlet 11 are arranged on the side wall of the gas collection chamber for connecting with external gas The tube is connected to the air tube. The upper part of the gas collection chamber 9, 10 is the regenerator 4, 12, the outside of the regenerator is a metal cavity 25 of steel structure, and the inner side of the metal cavity 25 is lined with a heat insulating material 8 for heat preservation and a high temperature resistant high temperature refractory material 7. A refractory partition wall 6 is built in the regenerator chamber to divide the regenerator chamber into a gas regenerator chamber 4 and an air regenerator chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com