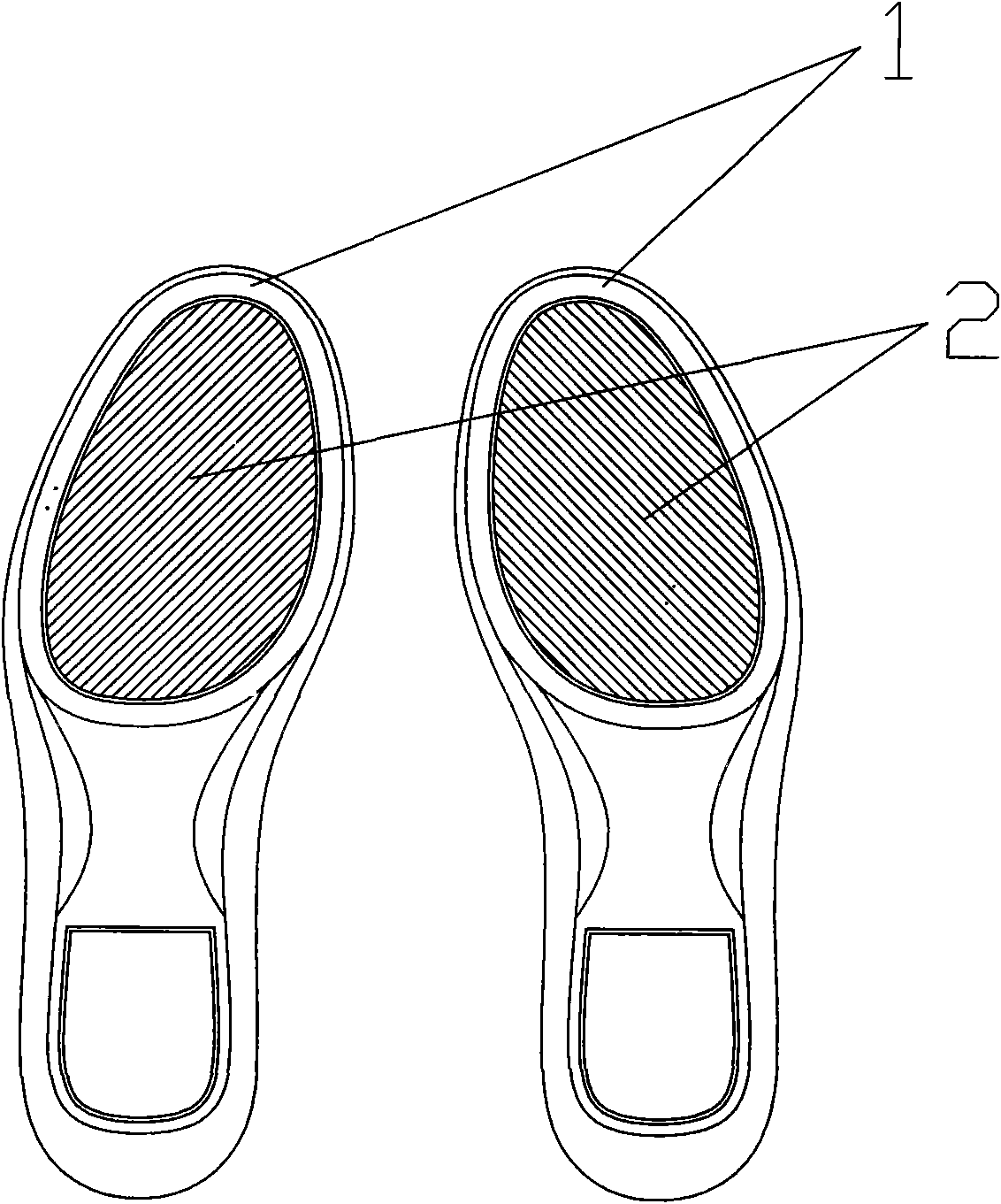

Soles and manufacture method thereof

A manufacturing method and technology for soles, which can be applied to soles, footwear, clothing, etc., can solve the problems of excessively hard bending effects of soles, poor comfort performance, and increased weight of soles, and achieve good bending performance, good wear resistance, and thickness of soles thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

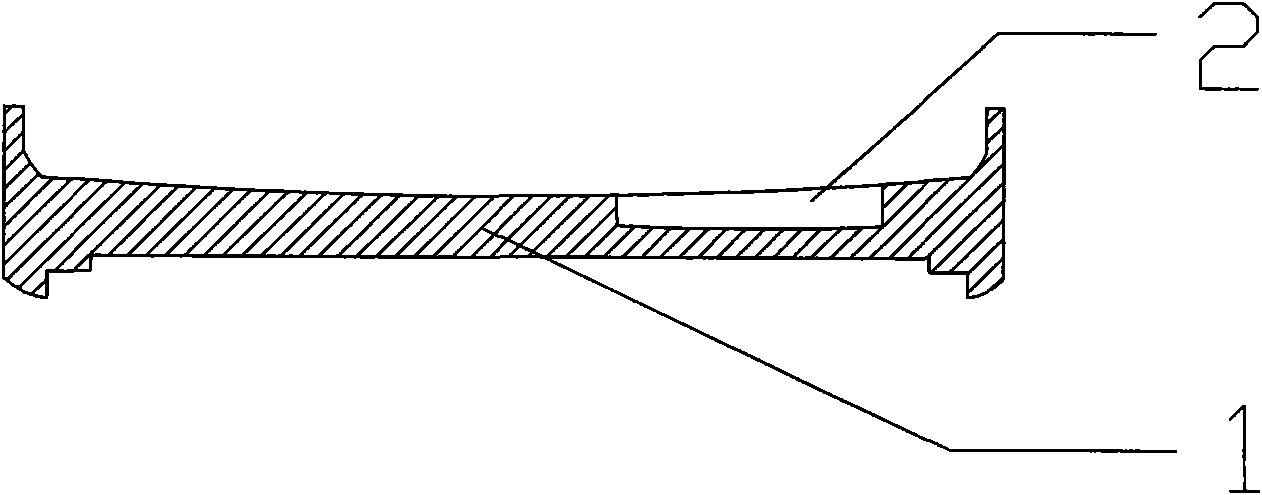

[0017] Set the rubber and raw rubber raw materials, the hardness of the outer periphery of the outsole is 85°, and the hardness of the middle raw rubber is 75°, and the prepared raw materials and fillers are added to 10,000 horsepower for banburying for 450 seconds; the materials are discharged into blocks To form a semi-finished product, add sulfur, accelerator and color glue to the raw material of the rubber semi-finished product, knead for 350 seconds and place it in a roller machine to press out the sheet, place the rubber base material in the mold for 400 seconds to prepare the outer periphery of the sole; The good rubber bottom material is placed in another mold, and then the raw rubber material is placed in the middle of the rubber bottom material, and it is molded for 300-400 seconds to prepare the sole heart, trimmed, and pasted with a film for storage after printing.

Embodiment 2

[0019] Set the rubber and raw rubber raw materials, the hardness of the outer periphery of the outsole is 80°, and the hardness of the middle raw rubber is 70°. Add the prepared raw materials and fillers into the 10,000 horsepower for banburying for 350 seconds; make the material into a block For the semi-finished product, add sulfur, accelerator and color glue to the semi-finished rubber raw material, knead for 300 seconds, place it in a roller machine to press out the sheet, place the rubber bottom material in the mold for 300 seconds to prepare the periphery of the sole; Place the raw rubber base material in another mold, then place the raw rubber material in the middle of the rubber base material, and mold for 300-400 seconds to prepare the sole heart, trim the edge, and store it with a film after printing.

Embodiment 3

[0021] Set the raw materials of rubber and raw rubber, the outer hardness of the outsole is 90°, and the hardness of the middle raw rubber is 75°. Add the prepared raw materials and fillers to 10,000 horsepower for banburying for 500 seconds; make the material into a block For semi-finished products, add sulfur, accelerator and color glue to the raw materials of rubber semi-finished products, knead for 400 seconds, place them in a roller machine to press out the sheets, place the rubber bottom material in a mold for 450 seconds to prepare the outer periphery of the sole; Place the raw rubber base material in another mold, place the raw rubber material in the middle of the rubber base material, and mold for 400 seconds to prepare the sole peach heart, trim the edge, and store it with a film after printing.

[0022] The performance measurement of the sole of the present invention is carried out at normal temperature under a bending resistance test at a right angle of 90 degrees. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com