Micro-channel absorber for absorbing H2S

A technology of absorber and microchannel, which is applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve time-consuming and labor-intensive problems, and achieve the effects of uniform distribution, compact structure, and large gas volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

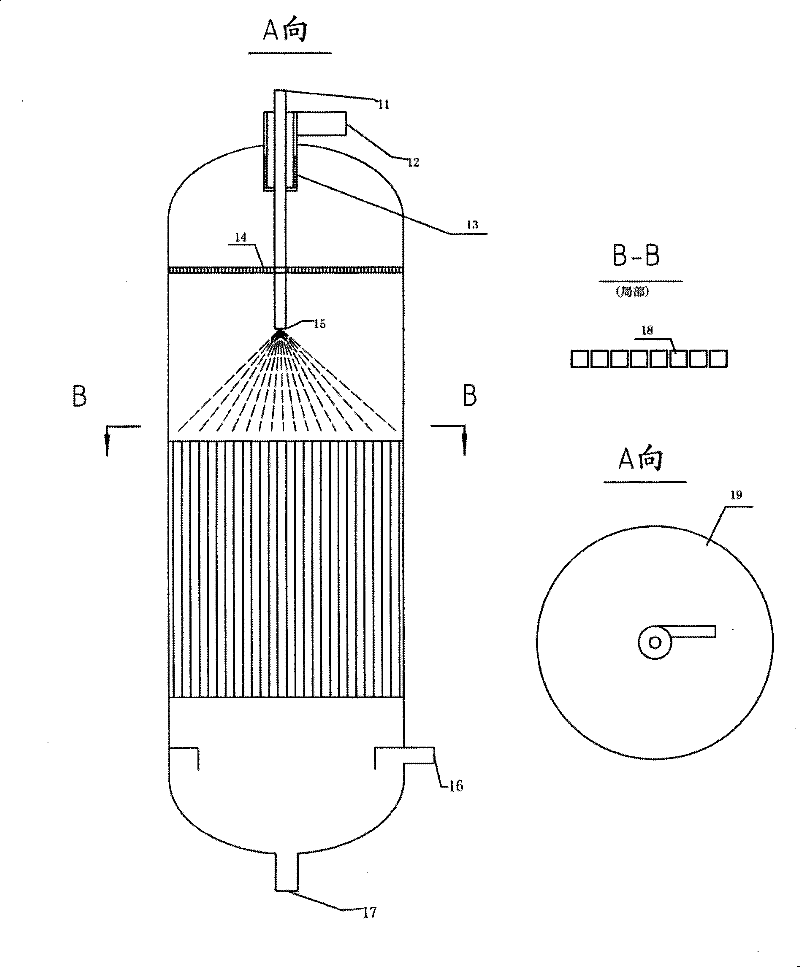

[0023] Microchannel absorber of the present invention ( figure 1 ), an absorbing H 2 The microchannel absorber of S comprises an absorber body, a lean liquid absorption liquid inlet and a gas tangential inlet are respectively arranged on the upper part of the absorber body, and a gas outlet and a rich absorption liquid outlet are respectively arranged on the lower part of the absorber body; There are 2 or more parallel micro-channels in the middle of the device body, and the two ends of the micro-channels are provided with an entrance common passage area and an exit common passage area; there are 1-5 layers between the gas inlet and the entrance common passage Layer-by-layer gas distributor; a liquid distributor is arranged between the inlet of the lean liquid absorption liquid and the common channel of the inlet;

[0024] The equivalent diameter of each microchannel can be selected according to the requirements of the specific decarburization process, and the specific range ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com