Preparation method of medium temperature desulfurating agent

A desulfurizer, medium-temperature technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of wide applicability, improved stability, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

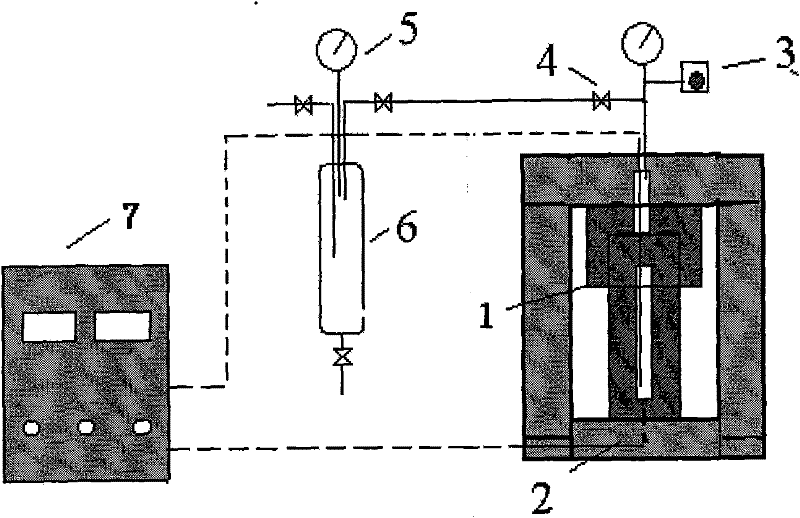

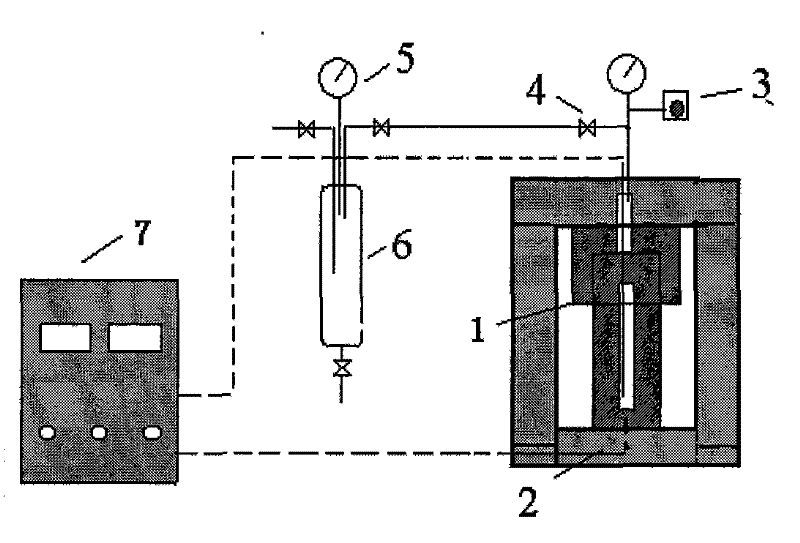

Image

Examples

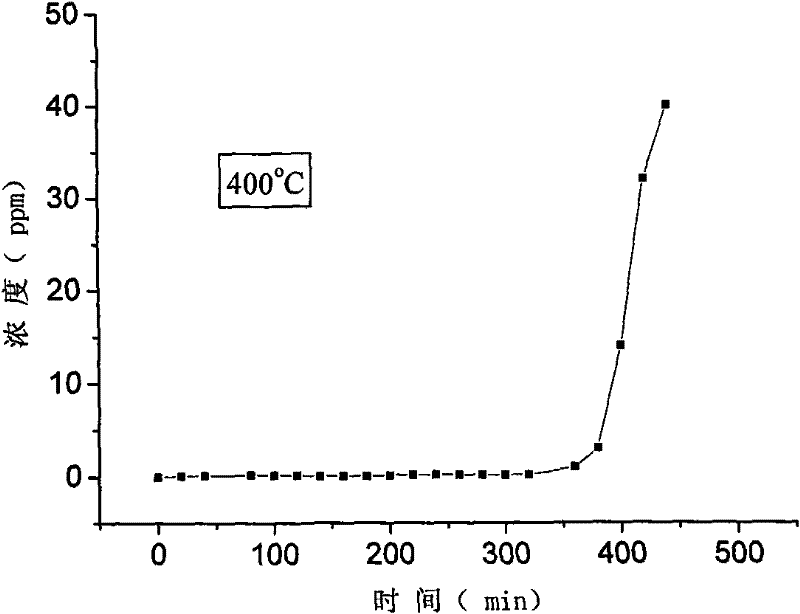

Embodiment approach 1

[0030] The concentration of 100ml is 2.87×10 -4 mol / ml manganese acetate solution and 20g of γ-Al 2 o 3Put it into a supercritical water reactor. Then heat the reactor to make the reactants reach the supercritical state of water at 380°C and 21.8MPa, and stay in the reactor for 30 minutes to react. After the reaction is over, the reaction product is separated in the gas-liquid separation tank by reducing the pressure, and the solid phase product remains at the bottom of the reaction tank. After the reaction kettle is cooled, the solid-phase product can be taken out to obtain the medium temperature desulfurizer called in the present invention, which is loaded on the carrier γ-Al 2 o 3 The mass percentage of manganese oxide is 10.8%, and this desulfurizer can be directly used for desulfurization activity evaluation without subsequent treatment. Fill 10ml of the above-mentioned desulfurizer in a fixed-bed quartz reactor, and carry out five desulfurization cycles at 400°C. Th...

Embodiment approach 2

[0032] The concentration of 100ml is 2.87×10 -4 mol / ml manganese nitrate solution and 20g of γ-Al 2 o 3 Put it into a supercritical water reactor. Then heat the reactor to make the reactants reach the supercritical state of water at 380°C and 21.8MPa, and stay in the reactor for 60 minutes to react. Other steps are as in the first embodiment, the intermediate temperature desulfurizer of the present invention is obtained, and it is loaded on the carrier γ-Al 2 o 3 The mass percent content of manganese oxide on it is 11.2%. The desulfurization evaluation at 400°C shows that the mechanical strength of the desulfurizer after 5 cycles is between 12.99-14.05N / mm (the fresh desulfurizer produced in this embodiment is 14.98N / mm), and the desulfurization accuracy is slightly reduced. The desulfurization accuracy of fresh desulfurizer can reduce H 2 S is removed from 400ppm at the inlet to <0.5ppm, but after the fifth regeneration, it can only be removed to <1ppm.

Embodiment approach 3

[0034] The concentration of 100ml is 2.87×10 -4 mol / ml copper nitrate solution and 20g γ-Al 2 o 3 Put it into a supercritical water reactor. Then heat the reactor to make the reactants reach the subcritical state of water at 350°C and 14.8MPa, and stay in the reactor for 15 minutes to react. Other steps are as in the first embodiment, the intermediate temperature desulfurizer of the present invention is obtained, and it is loaded on the carrier γ-Al 2 o 3 The mass percent content of the upper copper oxide is 10.0%. The desulfurization results at 400°C and 450°C show that the desulfurization accuracy of this desulfurizer is very poor (after 10 minutes of desulfurization, the concentration at the outlet reaches more than 10ppm), and the mechanical strength of the fresh, 400°C and 450°C desulfurizers are respectively 9.06 , 8.86, 9.00N / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com