Manufacturing method of dustproof unit

A manufacturing method and a dust-proof technology, which are applied in the fields of pollution prevention methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of uneven force, increased material cost, deformation and damage, etc., to improve dust-proof performance. effect, avoid assembly tolerances, reduce the effect of deformation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

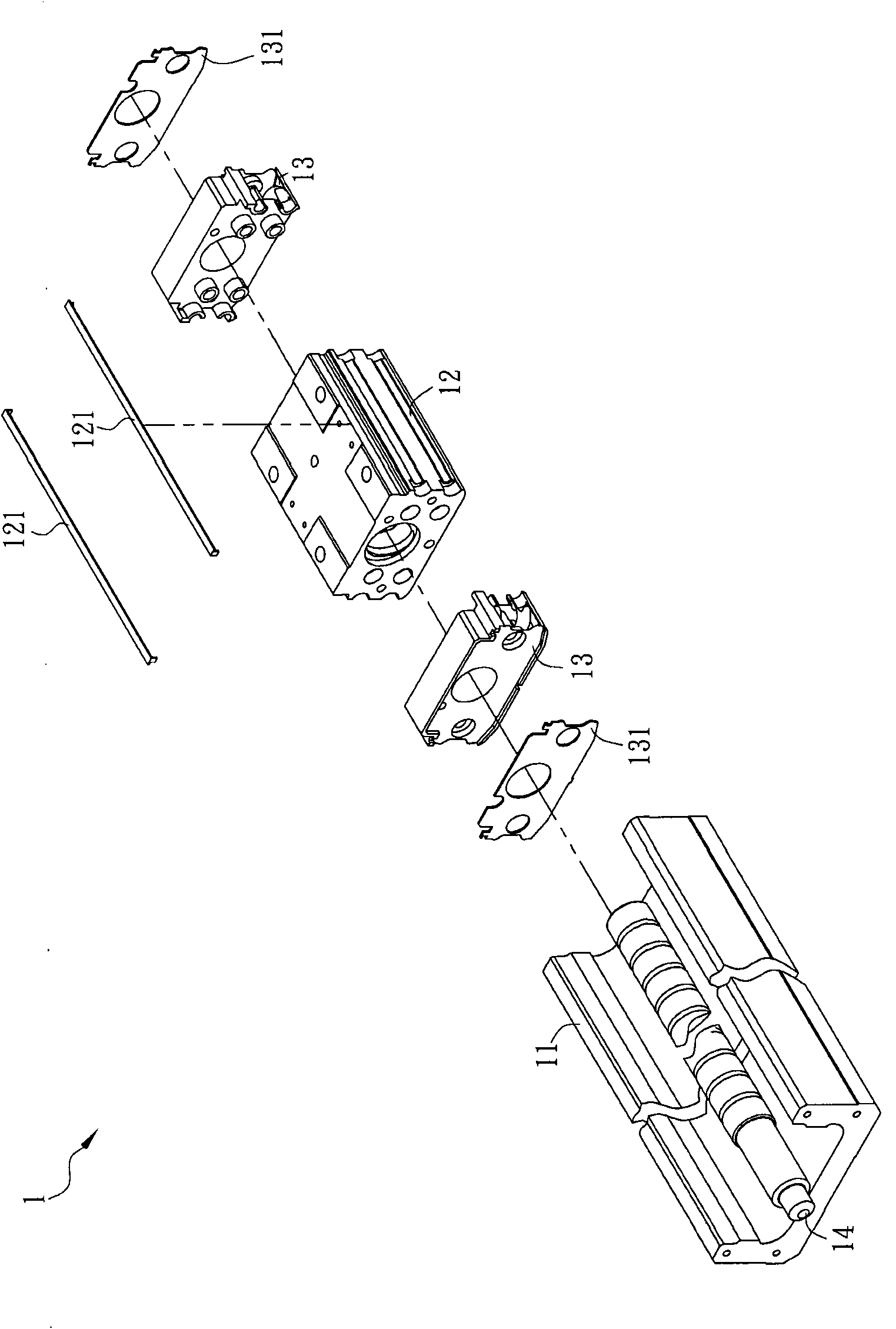

[0034] The method of manufacturing the dust-proof unit according to the preferred embodiment of the present invention will be described below with reference to the relevant drawings.

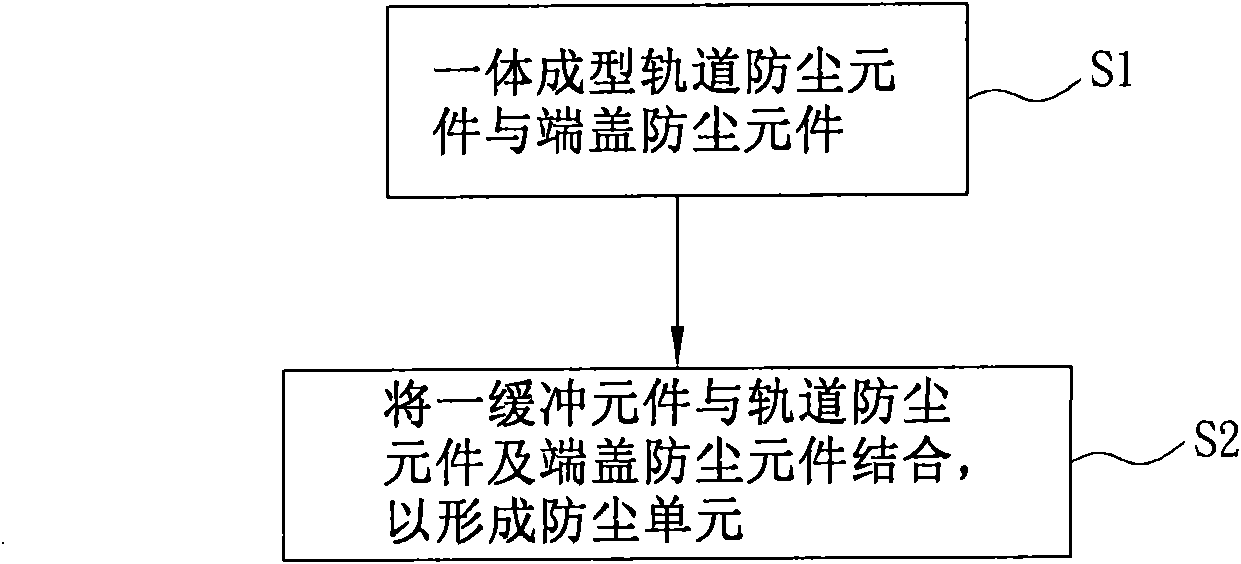

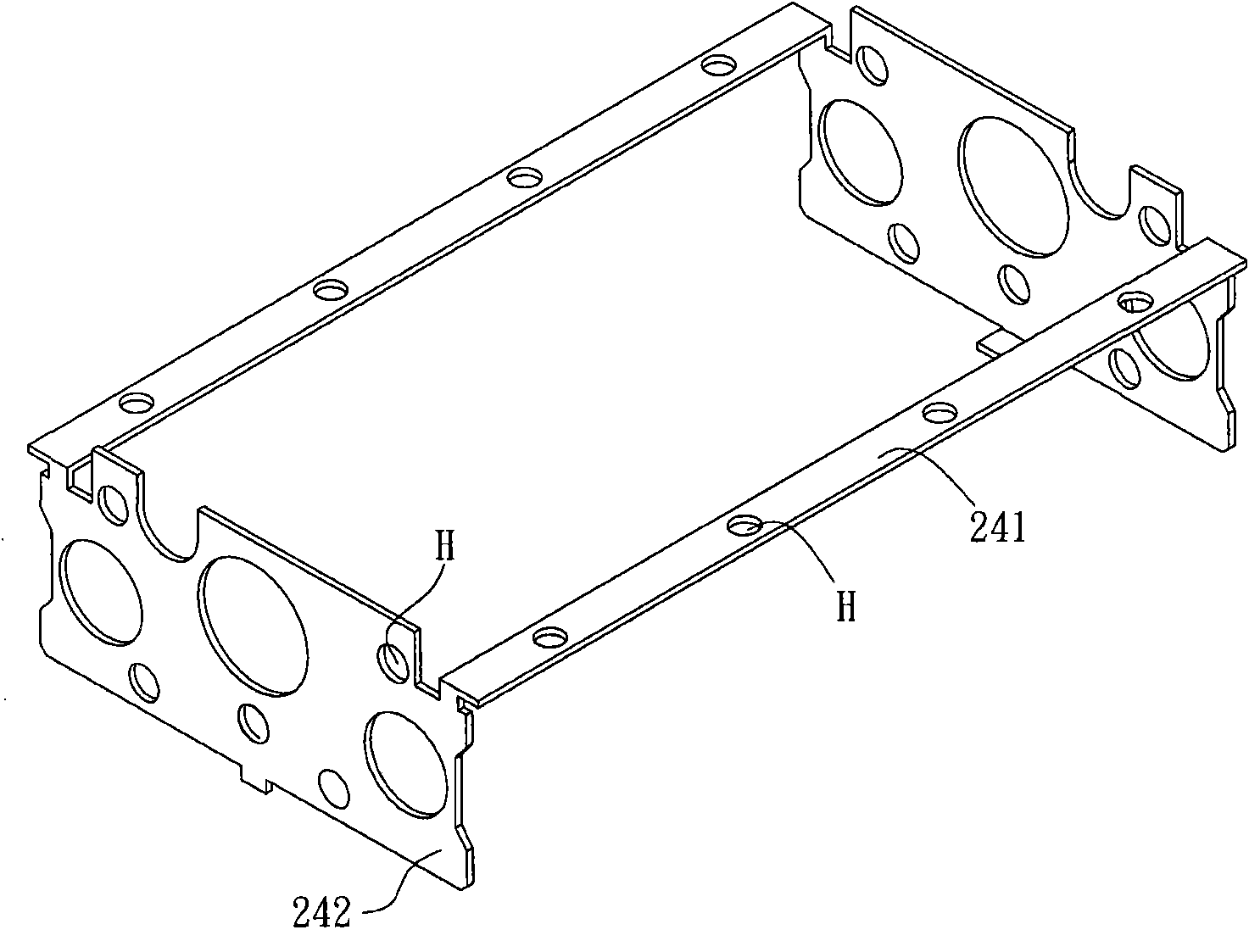

[0035] Please refer to figure 2 As shown, a method of manufacturing a dustproof unit of the present invention includes step S1 and step S2. Please refer to figure 2 and Figure 3A As shown, step S1 integrally forms the track dust-proof component 241 and the end cover dust-proof component 242 . In this embodiment, the two track dustproof components 241 and the two end cover dustproof components 242 are taken as examples for illustration. Wherein, the one-piece molding method, for example, uses the same mold to form the track dustproof component 241 and the end cover dustproof component 242, and then processes and bends the track dustproof component 241 and the end cover dustproof component 242, etc., but it is not limited.

[0036] The track dustproof element 241 and the end cap dustproof e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com