Anti-failure joint for mine exploration equipment

A survey equipment and a failure prevention technology, applied in the field of pipe joints, can solve the problems of easy deformation failure operation, cumbersome, unstable connection, etc., and achieve the effect of good anti-drop effect, improve work efficiency, and avoid connection failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

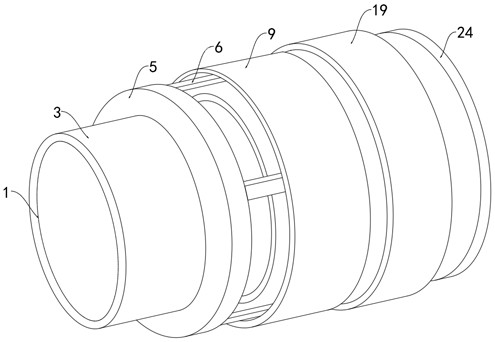

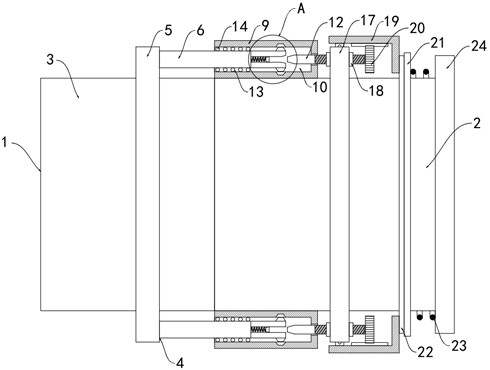

[0032] Such as Figure 1-6 As shown, a failure prevention joint for mine surveying equipment includes a connecting body 1, the connecting body 1 includes a matching joint mother body 2 and a joint cylinder 3, and a fixing mechanism 4 is arranged outside the connecting body 1;

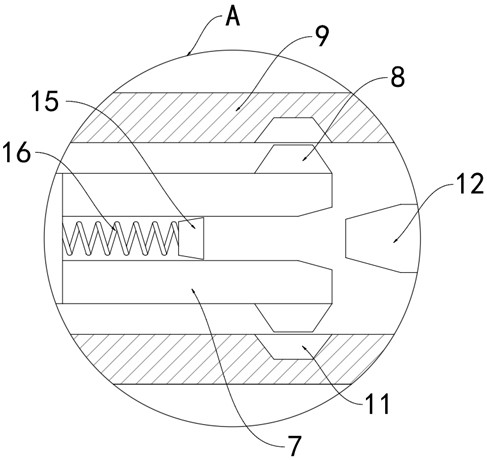

[0033] The fixing mechanism 4 includes a fixing ring 5, an extension plate 6, a claw 7, a block 8, a sleeve 9, an annular groove 10, a locking groove 11 and a push rod 12, wherein the fixing ring 5 is fixedly sleeved outside the joint cylinder 3 , one end of the extension plate 6 is fixed on the side wall of the fixed ring 5. In this embodiment, there are four extension plates 6, and the four extension plates 6 are arranged in a circular array, and each extension plate 6 is far away from the fixed ring. One end of the ring 5 is fixedly connected with two claws 7. The claws 7 are made of elastic material and have good elastic deformation performance. The two claws 7 are arranged symmetrically. The clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com