Special buckle automatic machining equipment for integrated wallboards

An integrated wallboard and automatic processing technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problem of low buckle processing efficiency, and achieve the effect of reducing deformation damage, avoiding easy damage, and maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

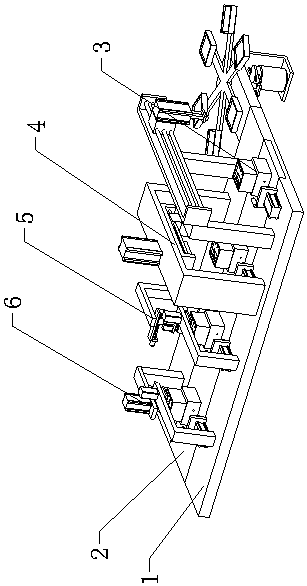

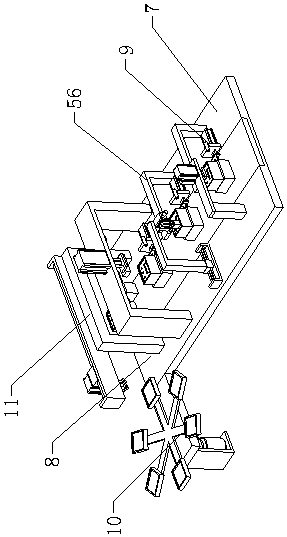

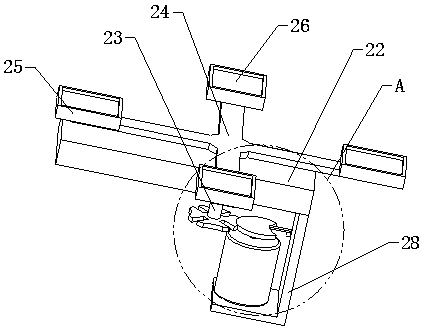

[0023] refer to Figure 1 to Figure 11 The shown automatic buckle processing equipment for integrated wall panels includes a workbench 1, a conveyor belt 2, a jig device 3, a feeding device, a punching device 4, a cutting device 5 and a bending and forming device 6. The workbench 1 is Rectangular plate structure, the conveyor belt 2 is set in the middle of the workbench 1 to isolate the workbench 1 into a left guide platform 7 and a right guide platform 8, the jig device 3 is evenly arranged in the middle of the conveyor belt 2, and the left guide platform Positioning devices 9 are arranged on the side near the fixture device 3 on the 7, and the feeding device includes a feeding mechanism 10 and a feeding mechanism 11, and the feeding mechanism 10 is arranged on the side of the right guide table 8, and The material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com