Auxiliary jacking device for slanting tip core of injection mould

A technology of injection mold and ejector device, applied in the field of inclined top core-pulling mechanism, can solve the problems of low efficiency, poor quality, and many labors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

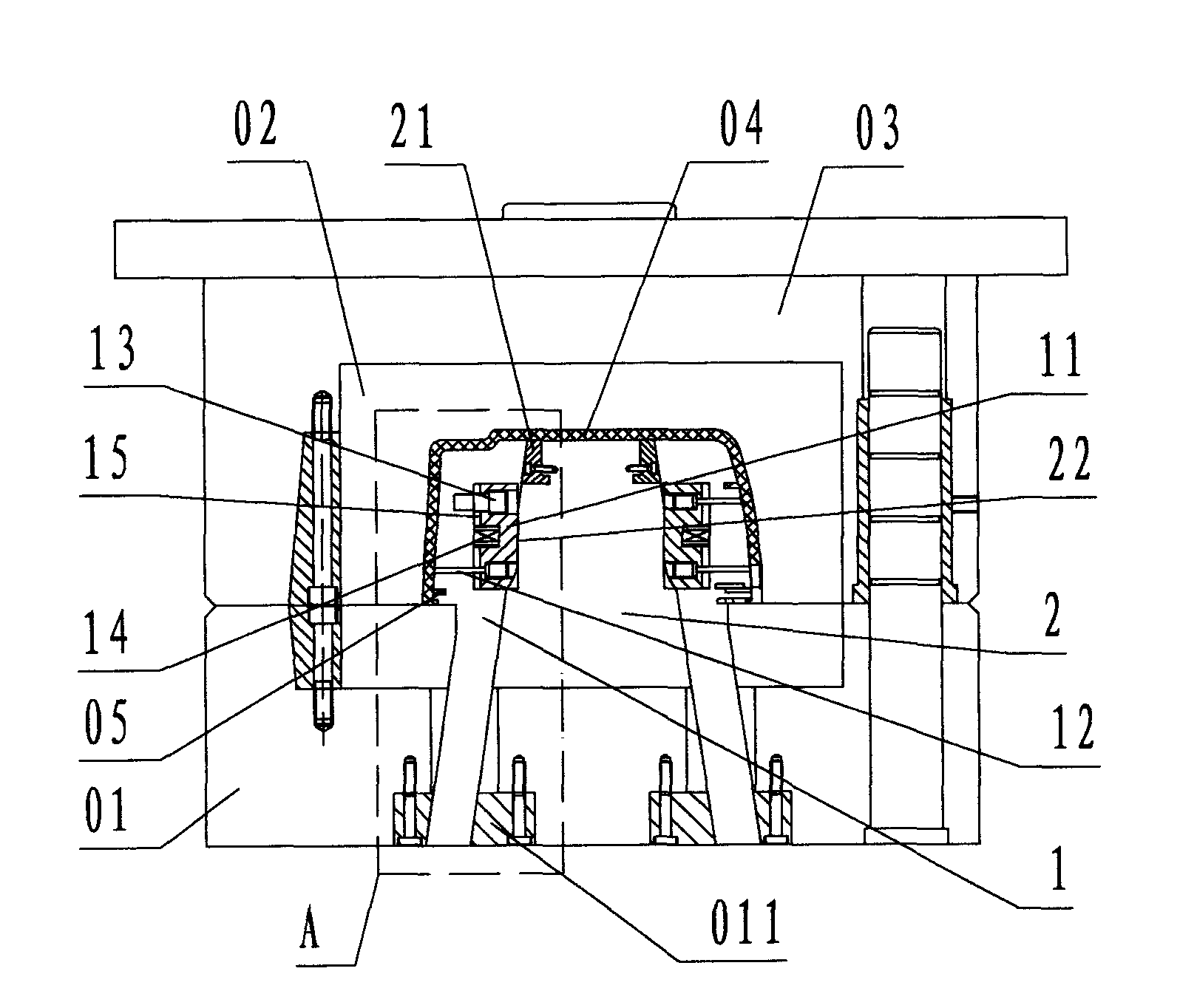

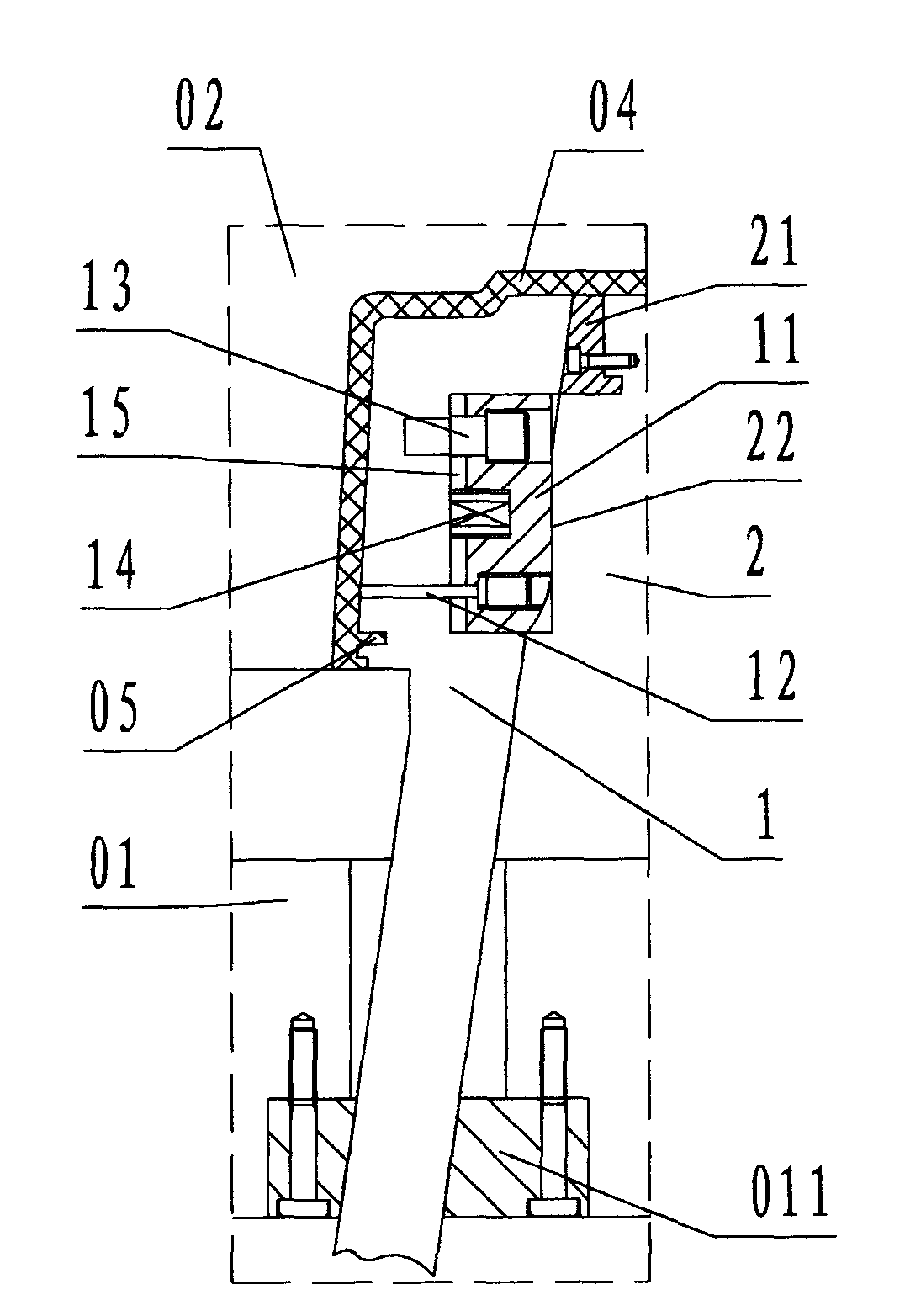

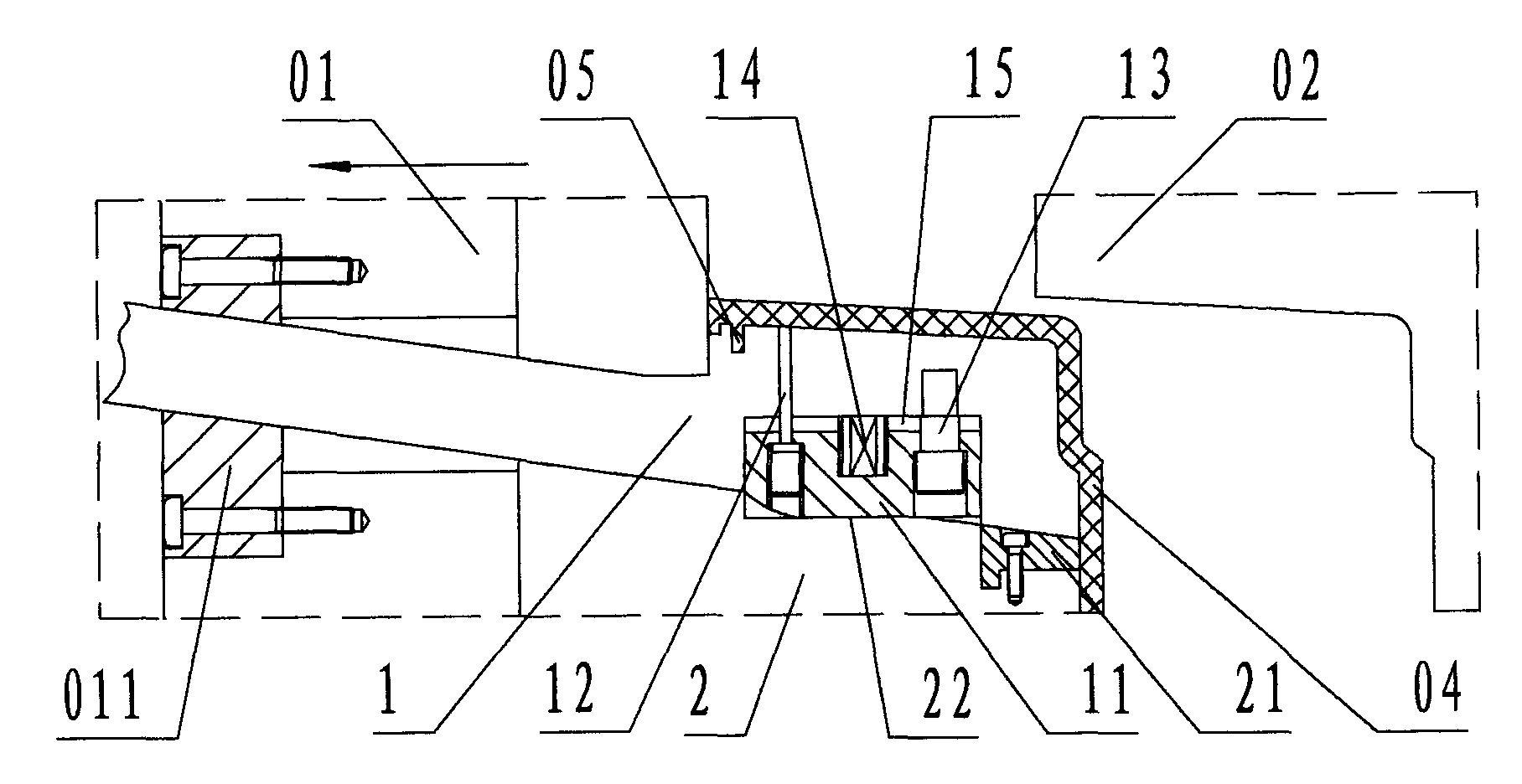

[0017] refer to Figure 1 ~ Figure 4 , an auxiliary ejector device for an inclined top core pulling of an injection mold according to the present invention, comprising an inclined ejector rod 1, a slider 11, an ejector pin 12, a limit bolt 13, a spring 14, and a core insert 2, wherein: the The inclined ejector rod 1 is a rod-shaped steel member with a rectangular cross-section, and a rectangular inclined ejector core block protruding from one side is provided at the upper end. A rectangular groove is provided on the side opposite to the protruding surface, and the angle between the central axis of the long side of the bottom of the rectangular groove and the axis of the rod-shaped body is equal to the angle between the inclined top of the inclined ejector rod 1 in the movable mold, that is, the angle with the movable mold. The vertical axis of the mold is parallel, the upper part of the bottom surface of the rectangular groove is provided with a blind screw hole, and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com