Pneumatic picking tension regulating device for simultaneously leading in multiple roots of weft

A tension adjusting device and tension technology, which are applied in textile, textile and paper making, looms, etc., can solve the problems of many times of hoisting, many times of nozzle work, high energy consumption of air-jet looms, etc., so as to increase the weft storage capacity, The effect of increasing diversity and reducing the number of jobs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

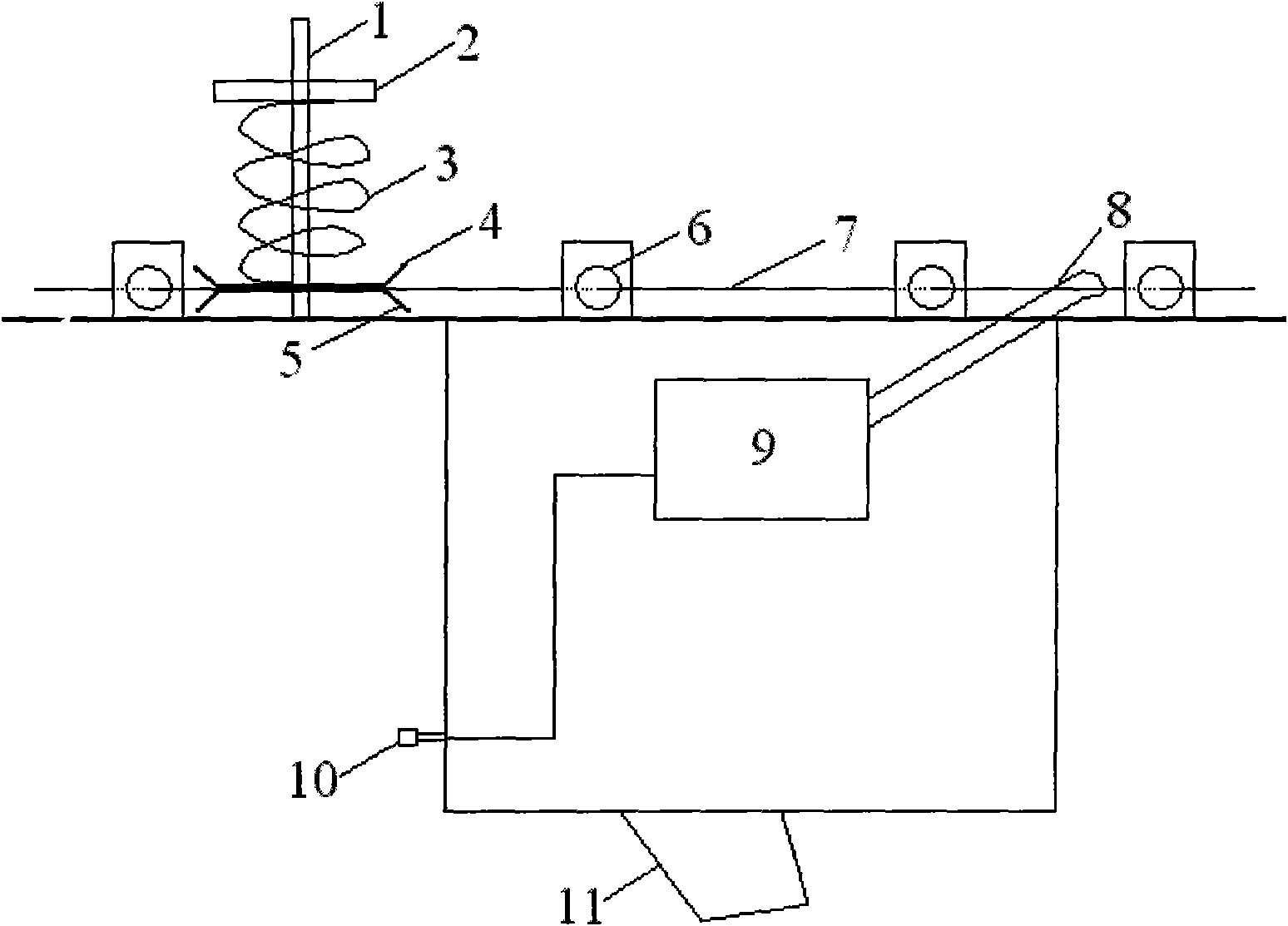

[0021] like figure 1 As shown, the air-jet weft insertion tension adjustment device for simultaneous introduction of multiple weft yarns according to the present invention includes a bolt 1, a nut 2, a spring 3, a first tension piece 4, a second tension piece 5, a yarn guide hole 6 and a platform base 11.

[0022] The bolt 1 is vertically fixed on one end of the base 11 platform, and the bolt 1 is provided with a nut 2 to cooperate with the bolt 1; one end of the spring 3 is fixed to the nut 2, and the other end is fixed to the first tension piece 4; the second tension piece 5 is connected to the first tension piece. The sheet 4 is opposite and arranged on the bolt 1 , the distance between the second tension sheet 5 and the base 11 is smaller than the distance between the first tension sheet 4 and the base 11 . Four yarn guide holes are equidistantly arranged on the base 11 platform.

[0023] The yarn 7 is located between the first tension sheet 4 and the second tension shee...

Embodiment 2

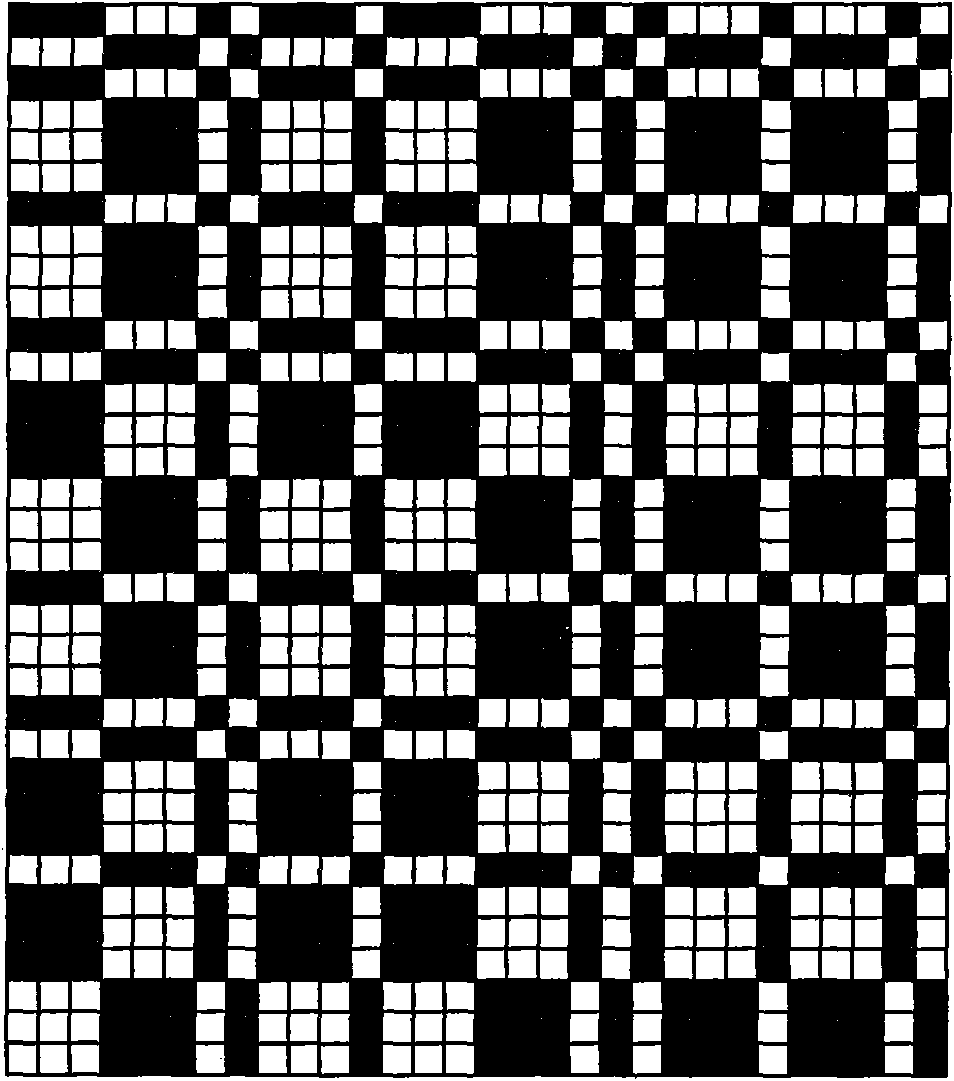

[0027] In the high-speed two-jet air-jet loom, the first weft feeder introduces a polyester low-elasticity yarn (DTY low-elasticity yarn), and the second weft feeder introduces three DTY low-elasticity yarns, and each DTY low-elasticity yarn passes through the Tension adjustment device for tension adjustment. The warp yarns are made of rayon, 30 per cycle, and the drawing-in sequence is: 1.1.1.2.2.2.3.4.5.5.6.1.1.1.2.2.2.3.4.5.6.6.6.6.1.2.2.2.3.4. The weft yarns are cardboard method. A: 1.3.5; A: 2.4.6; A 1.3.5; B 2.4.6; A 1.3.5; B 2.4.6; .6; A 1.3.5; B 2.4.6; A 1.3.5; A: 2.4.6; B 1.3.5; The tissue diagram of weaving rayon plaid fabric is as follows figure 2 .

[0028] figure 2 The shown weave needs 34 picks in the common air-jet loom weft insertion mode, but only 18 picks are needed after using the tension adjustment device and method of the present invention. It not only improves the weaving efficiency, but also saves energy.

Embodiment 3

[0030] High-speed four-jet air-jet loom, A weft feeder introduces a DTY low elastic yarn; B weft feeder introduces three weft yarns, which are linen yarn, cotton yarn and viscose yarn; C weft feeder introduces a cotton yarn ; The small weft feeder introduces three weft yarns, which are FDY filament, Tencel and nylon filament. Every weft yarn is tension adjusted by the tension adjustment device of the present invention. The four weft feeders can store 8 different weft yarns in total, which is twice that of ordinary air-jet looms of the same kind, greatly increasing the diversity of raw materials or designs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com