A kind of anti-run-flat tire spraying equipment and spraying method thereof

A spraying equipment and anti-leakage technology, applied in coating, spraying device, device for coating liquid on the surface, etc., can solve the problems of labor-consuming, inconvenient installation, difficult replacement, etc., to reduce work time and increase Work efficiency, the effect of speeding up work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

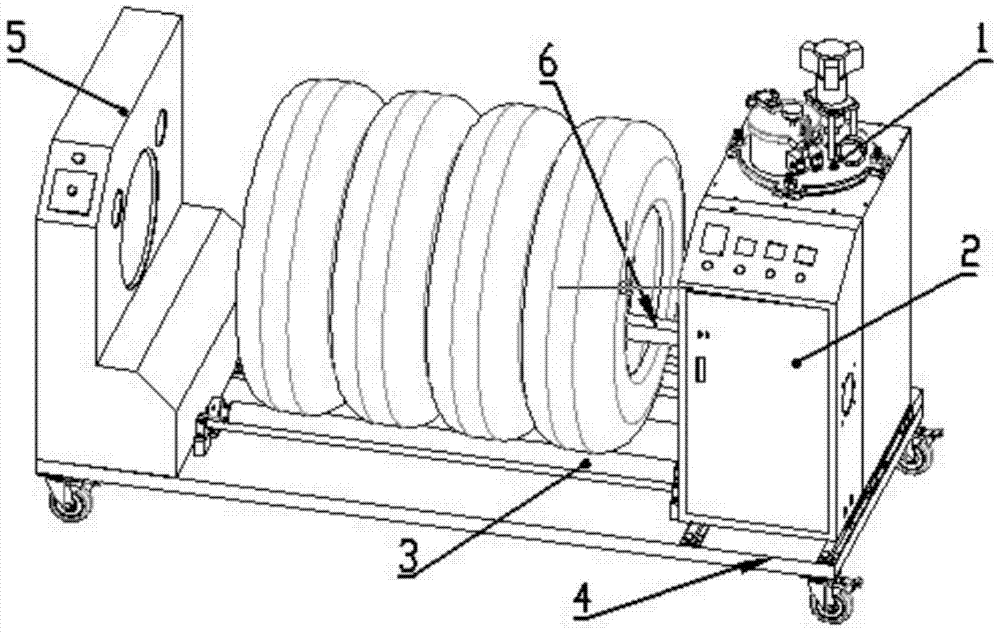

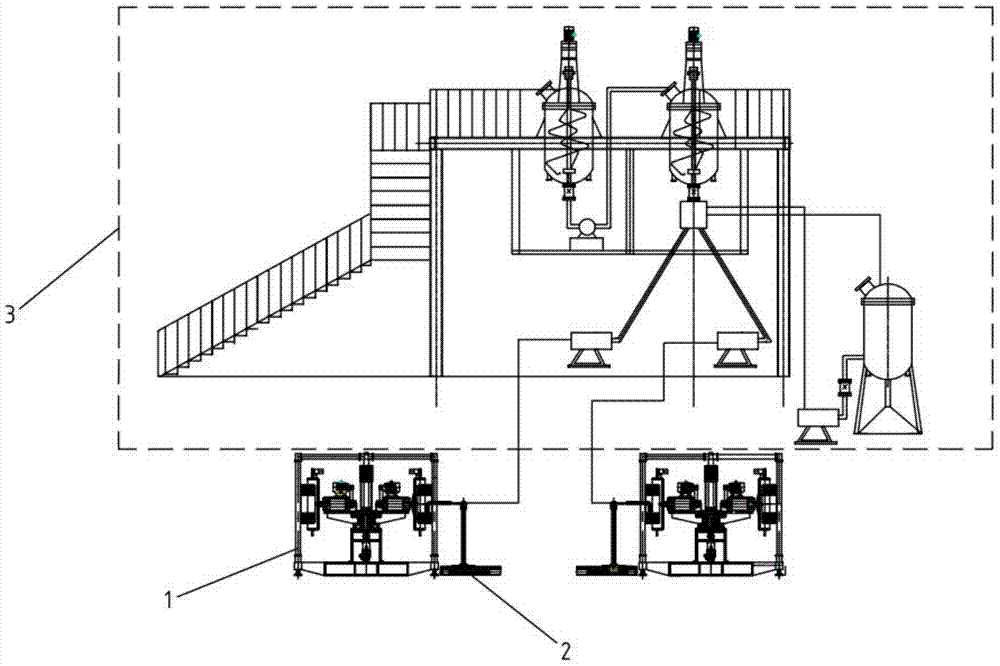

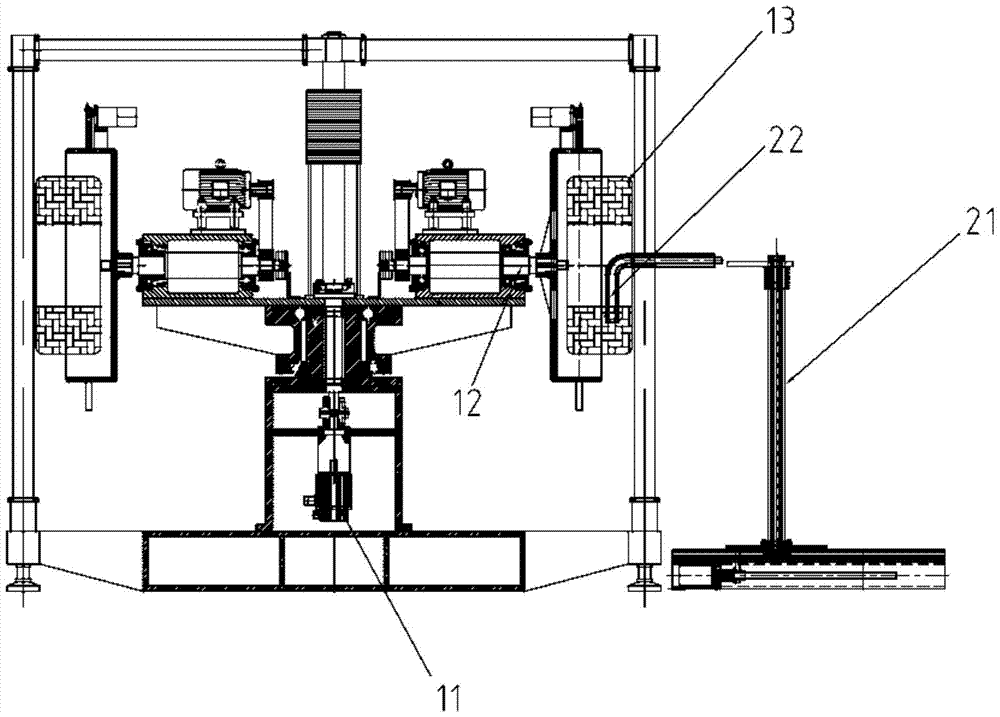

[0042] see Figure 2-4 , which is a schematic diagram of the overall structure of the anti-run-flat tire spraying equipment of the present invention, a schematic diagram of the work of the tire mounting device and the spraying device, and a schematic structural diagram of the sol device.

[0043] The anti-run-flat tire spraying equipment of the present invention includes a tire mounting device 1, a grinding device (not shown), a spraying device 2, a sol device 3 and a cooling device (not shown).

[0044] The tire installation device 1 is provided with four stations, which are respectively a loading and unloading station, a grinding station, a spraying station and a natural cooling station, and each station is respectively provided with an aluminum plate.

[0045] The tire mounting device 1 is provided with a central rotating drive part 11 for switching between different stations, and a tire loading and unloading part and a rotating part 12 respectively assembled on the aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com