Cable elbow head extraction tool

A technology of puller and cable elbow, which is applied in the field of cable elbow puller, can solve the time-consuming and labor-intensive problems of removing the cable head, and achieve the effects of shortening work time, saving manpower and material resources, and protecting external insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

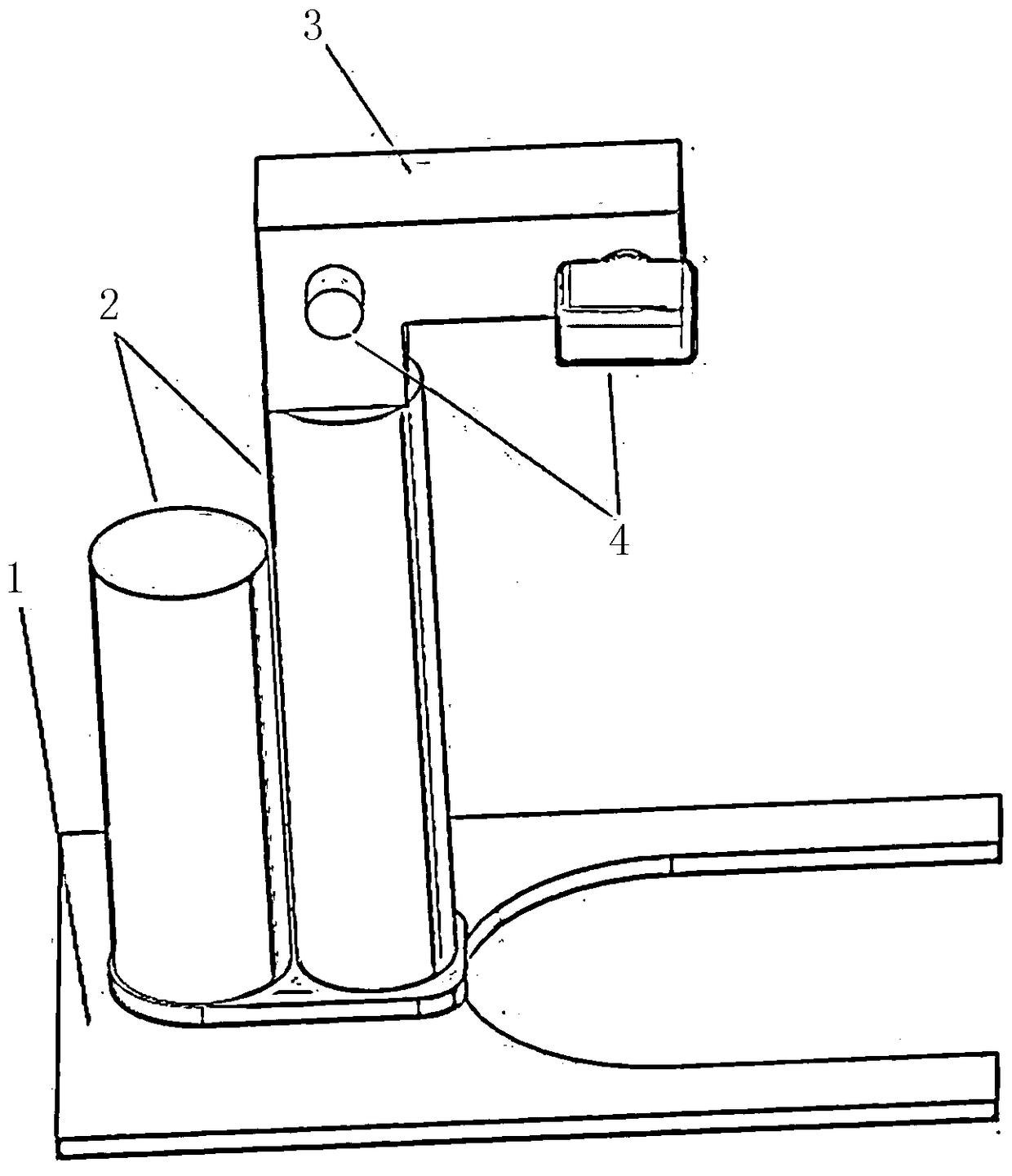

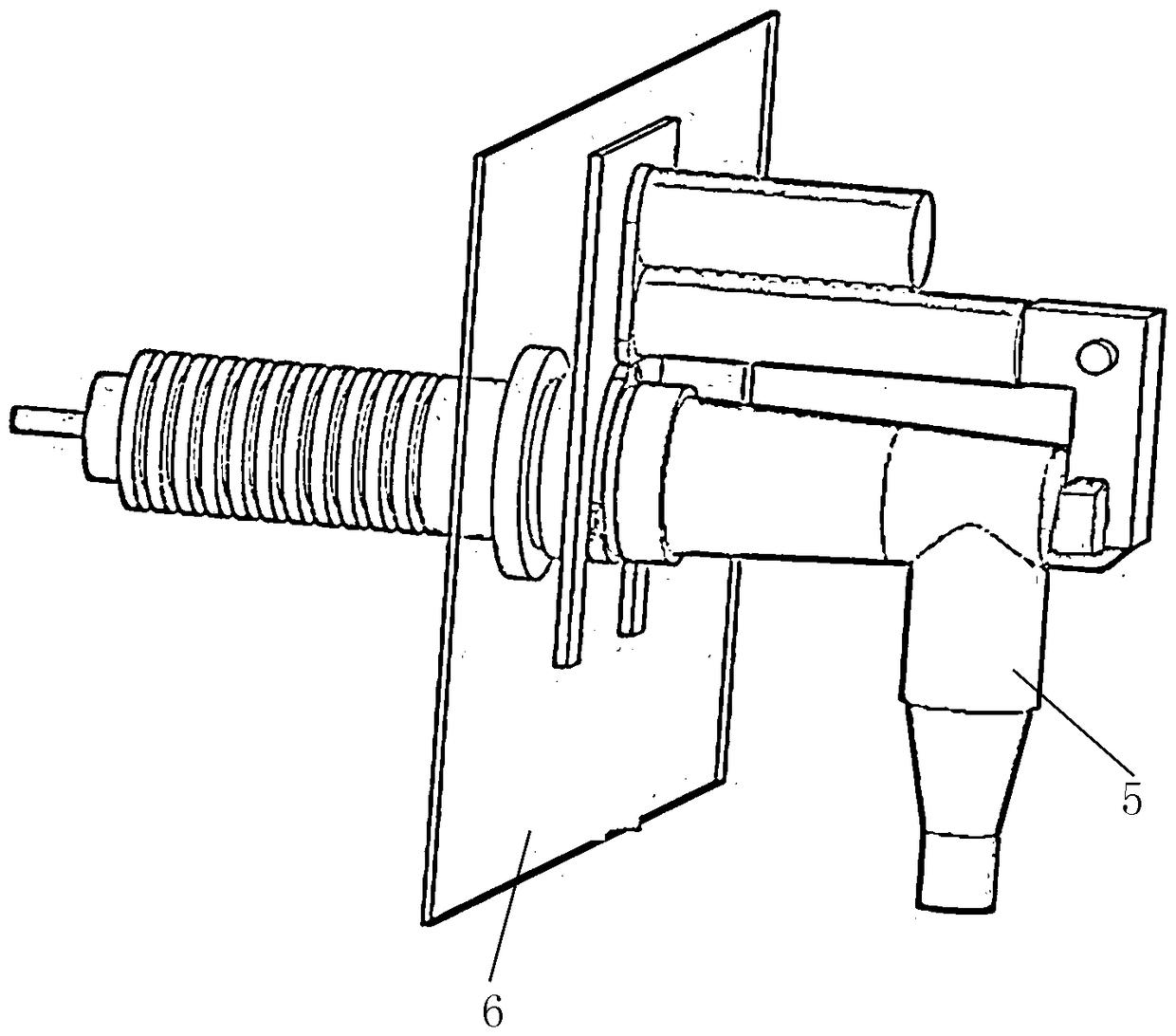

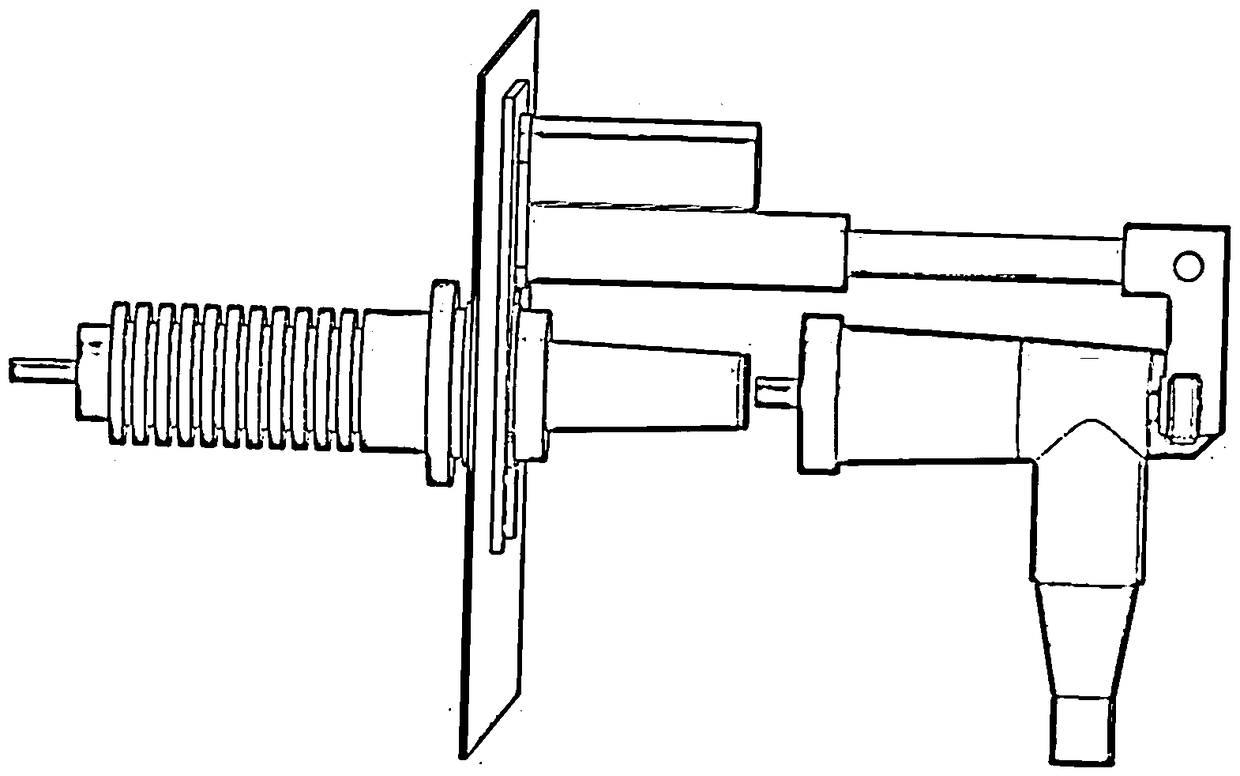

[0021] As shown in the figure, a cable elbow puller includes a puller fixing plate 1, an electric push rod 2 and a push rod joint 3, the base of the electric push rod is fixed on the puller fixing plate 1, and the electric push rod The telescoping end of rod 2 is connected with push rod joint 3, and the pull ring of push rod joint and cable elbow 5 is fixed.

[0022] The fixed plate of the puller is provided with a U-shaped arc groove, and the U-shaped arc groove is connected with the base of the cable elbow head.

[0023] match. The puller fixing plate is 200mm long and 130mm wide; it is made of glass fiber reinforced plastic epoxy resin material. It is used to fix the puller on the mounting plate of the cable elbow, and generates a reaction force during the pull-out process.

[0024] The electric push rod is 200mm long, 150mm wide, and the diameter of the push rod is 40mm; the power supply is DC24V, the thrust can reach up to 5000N, and the stroke is 200mm. Model Longxiang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com