Oil hydraulic cylinder for braking

A technology of hydraulic cylinders and brakes, applied in the direction of brake actuators, etc., can solve the problems of rising processing and assembly costs, lower product competitiveness, deadlocks, etc., to achieve easy manufacturing and assembly, enhance competitiveness, and simplify components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

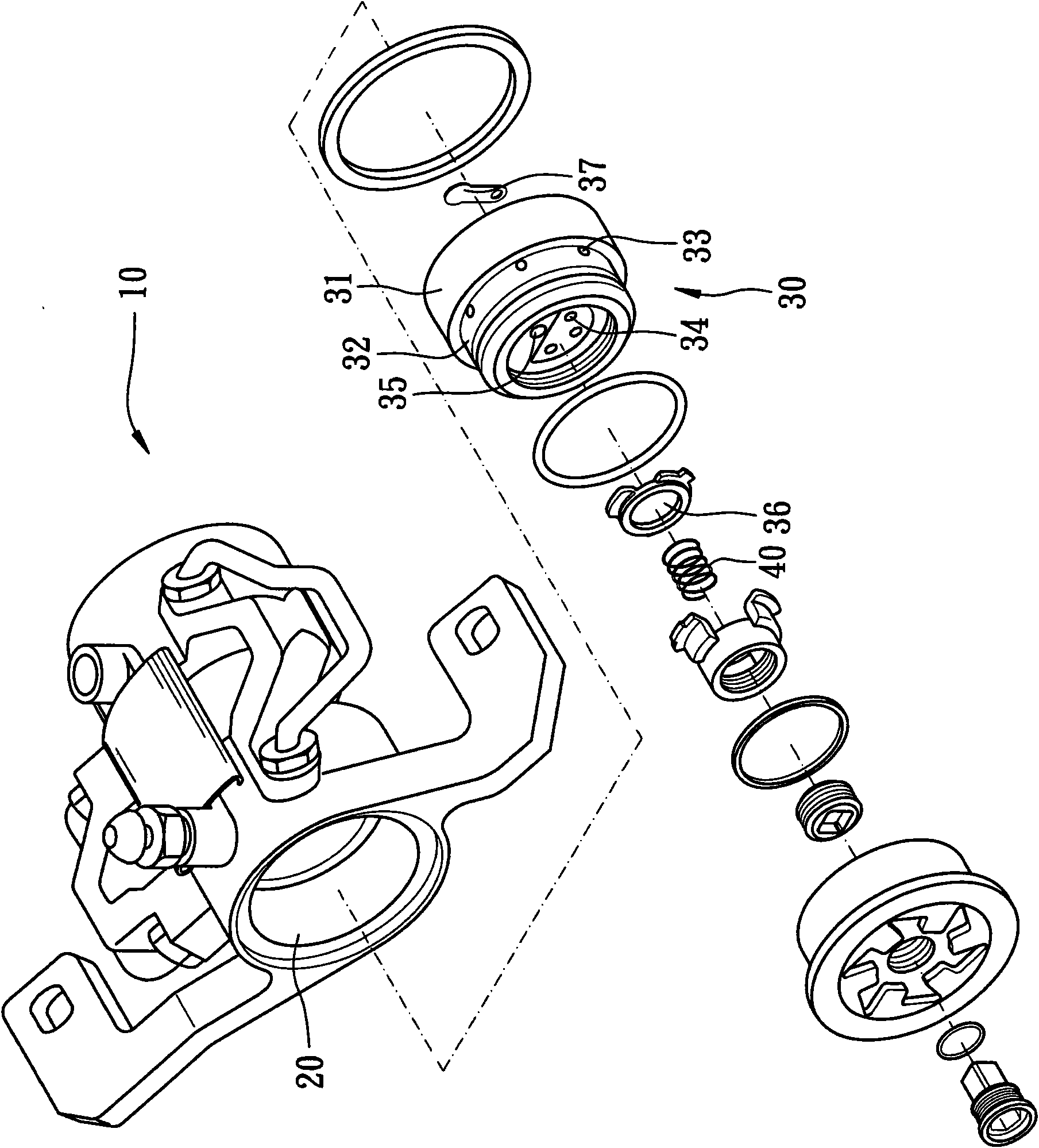

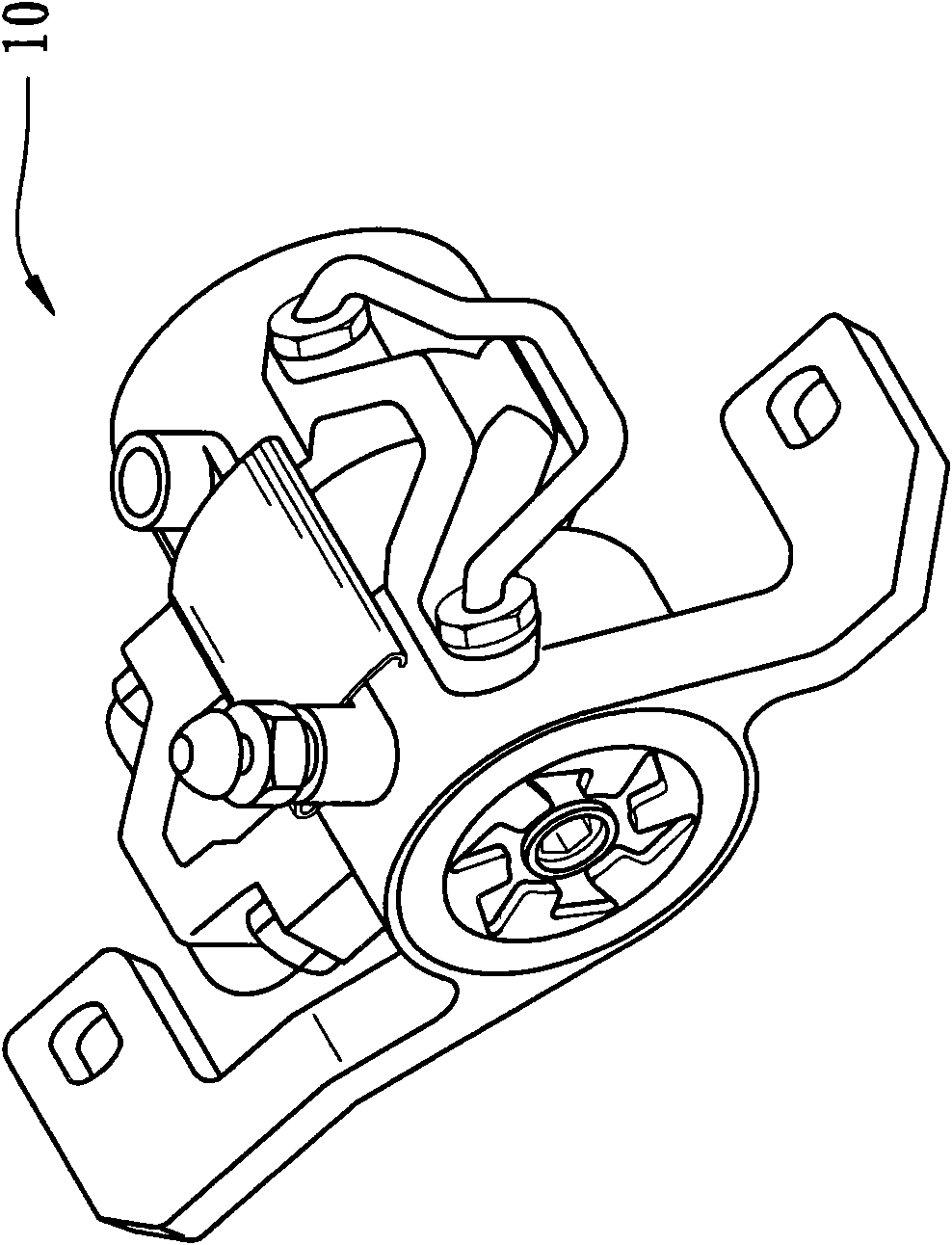

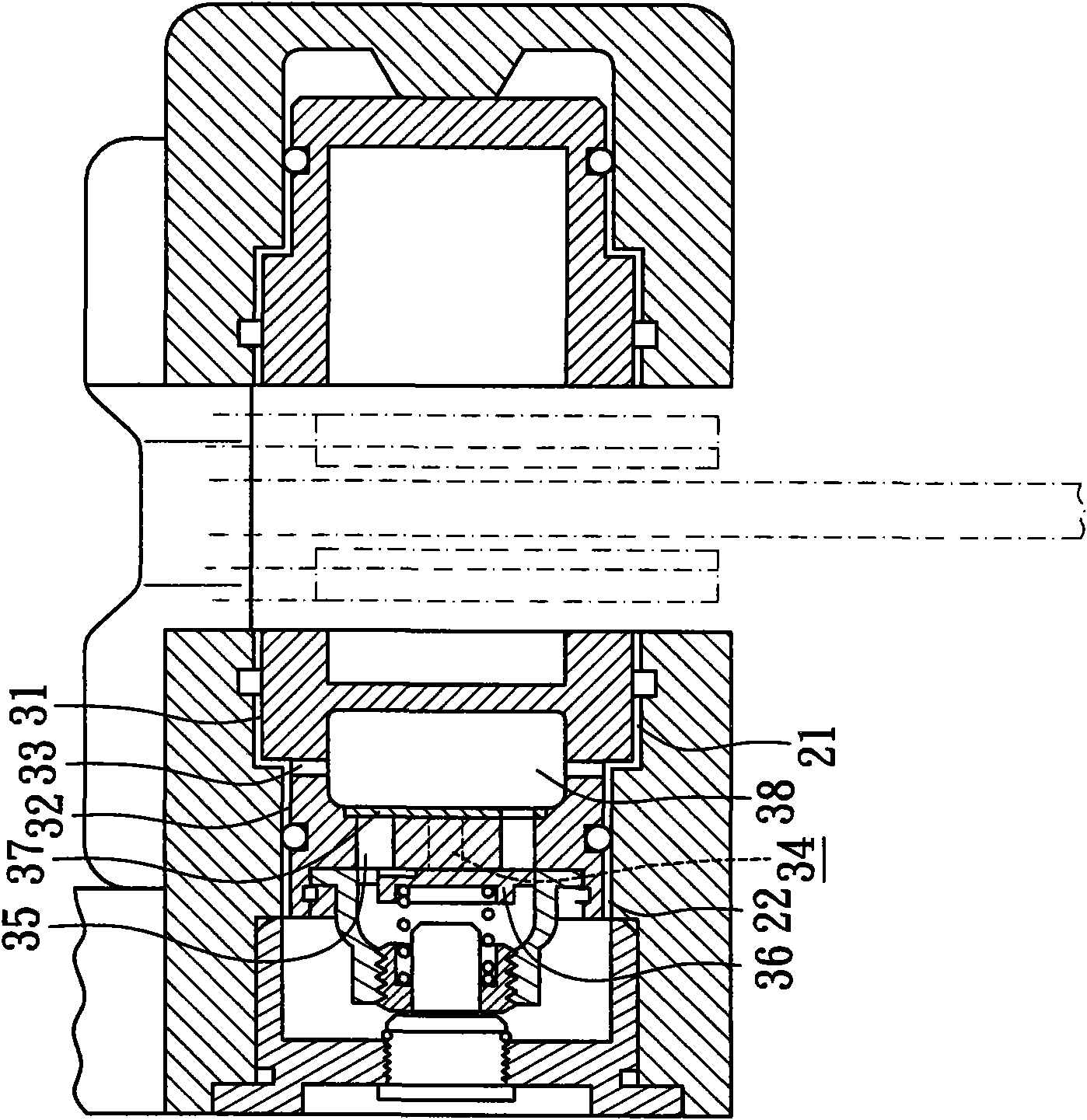

[0040] The present invention relates to a hydraulic cylinder for braking. The present invention can be applied to vehicles such as bicycles and motorcycles. The bicycle is used as an example to illustrate this example. In this embodiment, the hydraulic cylinder is used as a brake caliper 10 as an example. Please refer to Figure 1 to Figure 3 As shown, it includes a first hydraulic cylinder 20 and a first piston 30, wherein:

[0041] The first hydraulic cylinder 20 has an accommodating space, which is transverse to the inside of the first hydraulic cylinder 20, for accommodating the first piston 30 in a movable and sealed manner, and the accommodating space can According to the diameter, it is divided into a first chamber 21 and a second chamber 22, and the diameter of the second chamber 22 is smaller than that of the first chamber 21;

[0042] The first piston 30 has a first part 31 and a second part 32, and the first part 31 and the second part 32 are respectively movable a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com