Test system and test method of multiphysics fatigue property

A fatigue performance testing, multi-physics technology, applied in measurement devices, strength characteristics, instruments, etc., can solve problems such as the inability to effectively evaluate the fatigue performance of small piezoelectric ceramic samples, and achieve the effect of high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment approach

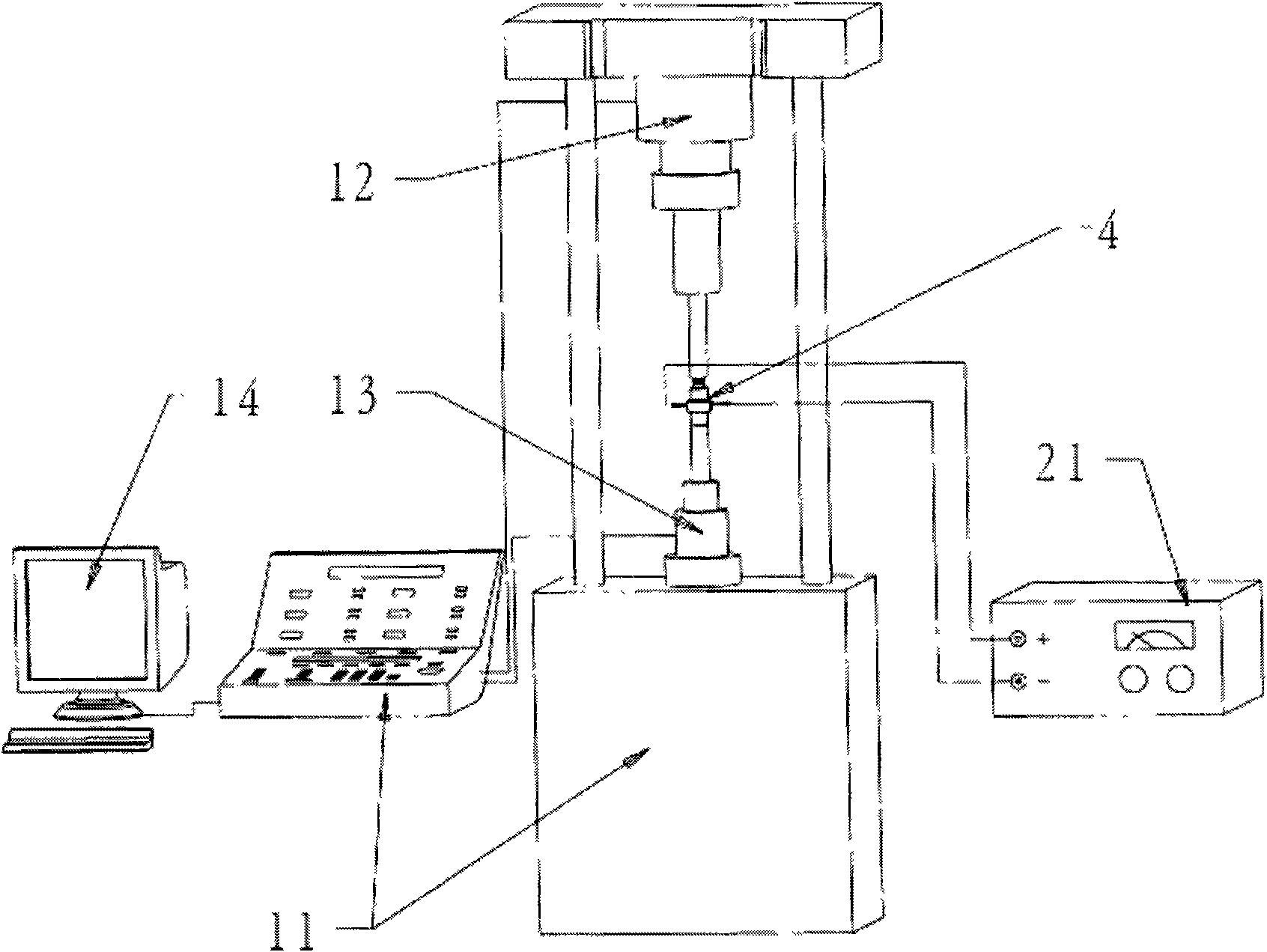

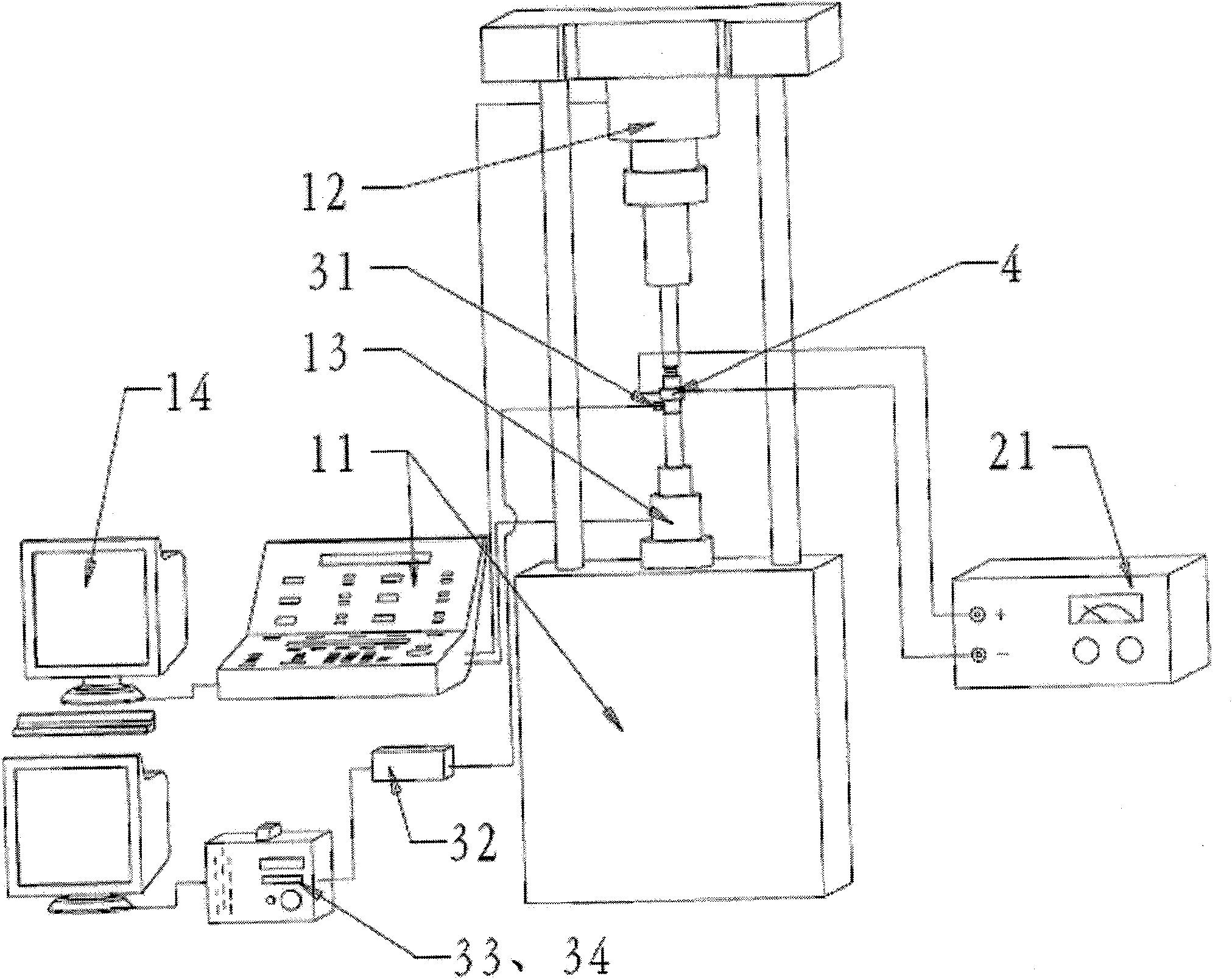

[0050] Step 1: Refer to attached figure 1 , the PZT sample (6) is built into the mold (4), and the center of the sample (6) is located on the axis of the mold (4), and the upper and lower surfaces of the sample (6) are connected to the high and low voltage of the high voltage power supply (21) respectively. terminal connection, refer to the attached figure 2 , the acoustic emission sensor (31) is connected to the outer surface of the mold (4);

[0051] Step 2: Set the material mechanical performance testing machine (11) to provide the amplitude (2N), frequency (5Hz) and waveform (half sine wave) of the load, the current form (AC) and the test voltage (1kV) provided by the high-voltage power supply (21) ;

[0052] Step 3: Start the material mechanical performance testing machine (11) and the high-voltage power supply (21), apply the electromechanical cyclic load in the vertical direction to the PZT sample (6), and give the electromechanical coupling cyclic loading by the aco...

Embodiment 2

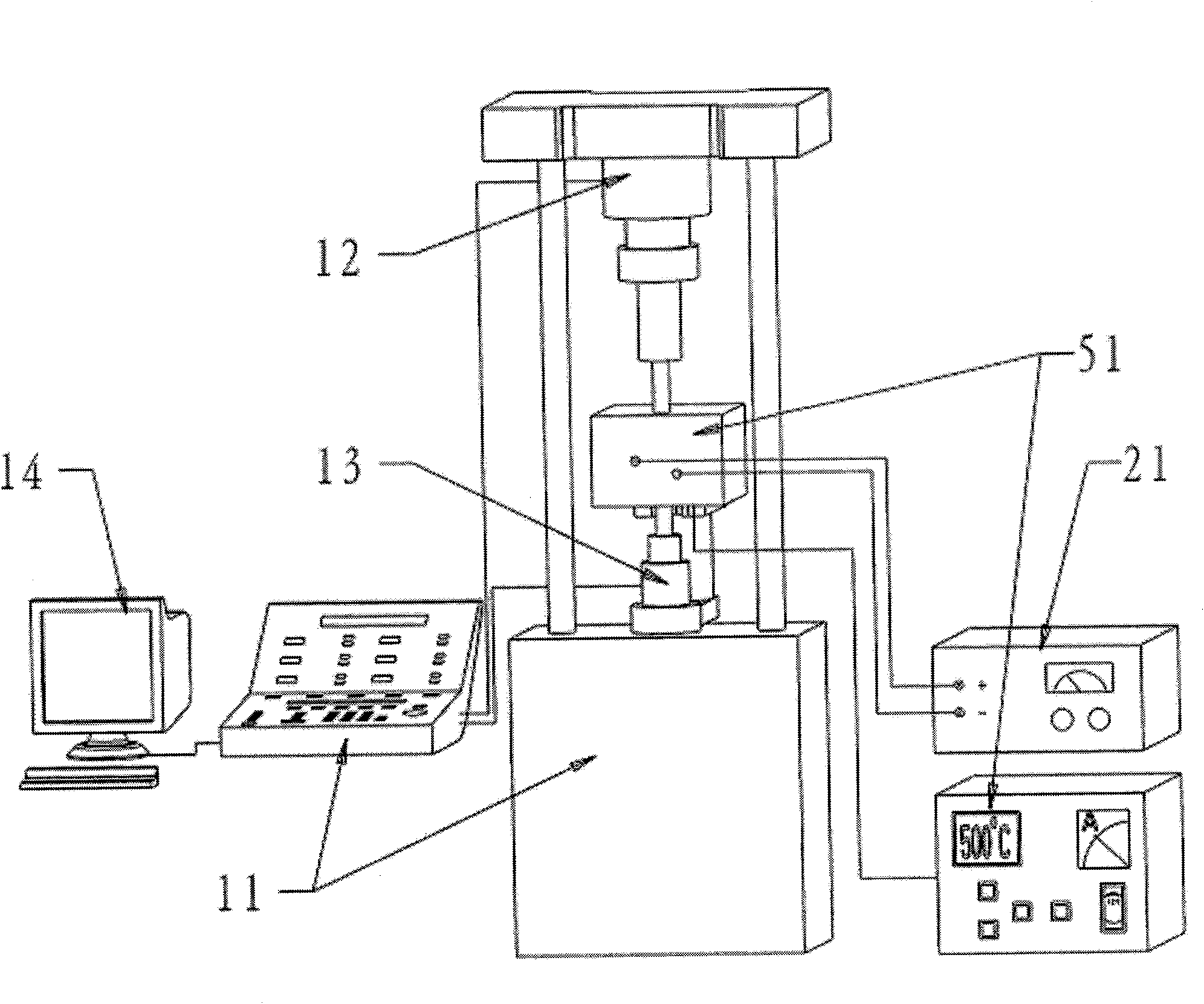

[0058] Implementation method of fatigue performance evaluation and life prediction of lead zirconate titanate (PZT) samples based on real-time monitoring of material damage and destruction under force-thermoelectric coupling conditions

[0059] With reference to specific embodiment 1, in step 1, with reference to the attached Figure 4 , connect one end of the waveguide rod (35) to the outer surface of the mold (4), and connect the other end to the acoustic emission sensor (31), refer to the attached image 3 , 4 , and further place the mold (4), part of the waveguide rod (35) in the cavity of the high temperature furnace (51); in step 2, further set the test temperature (120°C) of the high temperature furnace (51), and the high voltage power supply (21) test voltage (0.8kV); in step 3, start the high temperature furnace (51) further, carry out the cyclic loading of force thermoelectric coupling; other steps of force thermoelectric coupling are with the steps 4-7 of specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com