Energy-saving fruit juice and jam sterilizing machine

A sterilizer and jam technology, which is applied in the fields of food science, food preservation, and application, can solve the problems of wasting energy and incomplete sterilization, and achieve the effect of saving energy and complete sterilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

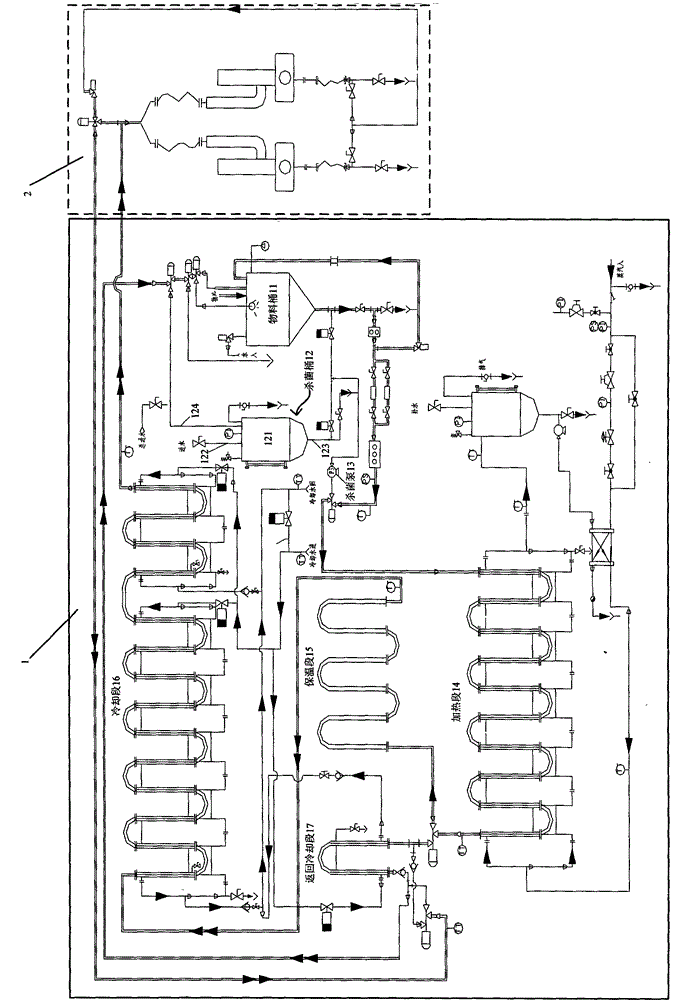

[0013] Hereinafter, the present invention will be described in detail with reference to the drawings.

[0014] See figure 1 , An energy-saving fruit juice jam sterilization machine 1, connected to the filling machine 2, used to sterilize materials, including: material barrel 11, sterilization barrel 12, sterilization pump 13, heating section 14, heat preservation section 15, cooling section 16 and Return to the cooling section 17, the material barrel 11, the sterilization pump 13, the heating section 14, the heat preservation section 15, the cooling section 16 and the filling machine 2 are connected in turn by pipelines, and the return cooling section 17 is respectively connected to the filling machine 2, the material barrel 11 and the heating section. The section 14 is connected by a pipeline, and the sterilization barrel 12 is connected with the sterilization pump 13, the cooling section 16 and the return cooling section 17 respectively.

[0015] The above-mentioned material bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com