Rubber water injection core mould

A rubber and mandrel technology, applied in ceramic forming cores, ceramic forming mandrels, ceramic forming machines, etc., can solve the problems of time-consuming and labor-intensive, low production efficiency, poor processing accuracy, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

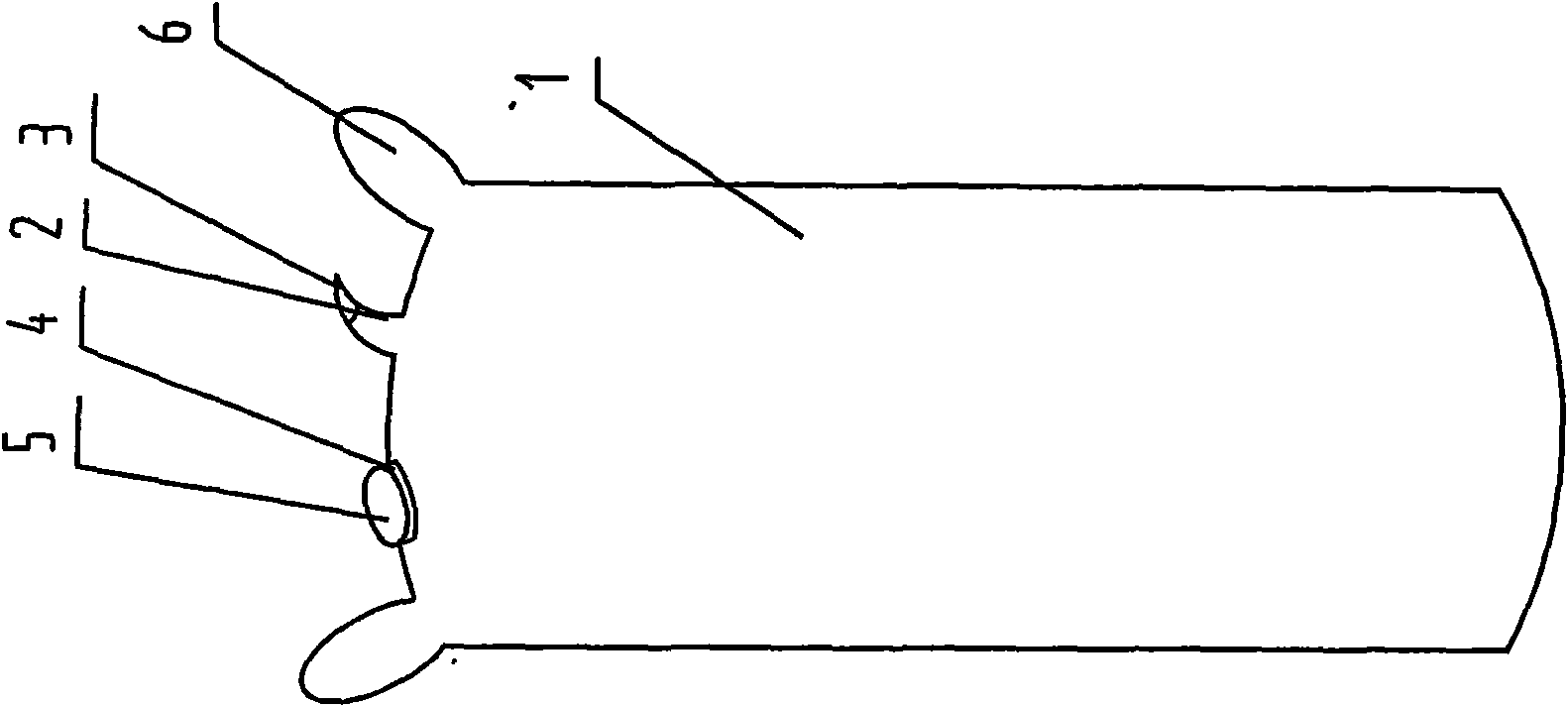

[0011] As shown in the figure, a rubber water injection mandrel is characterized in that: an inlet and exhaust nozzle 2 is installed on the top of the rubber water injection mold body 1, an upper cover 3 is placed on the inlet and outlet nozzle 2, and a rubber water injection mold body 1 The top of the top is also equipped with inlet and outlet ports 4, and the inlet and outlet ports are processed with threads, which are matched with a nozzle cover 5 with internal threads, and lifting lugs 6 are installed on both sides of the top of the rubber water injection mold body 1 to prevent the core mold from The core mold shifts due to different pouring bodies.

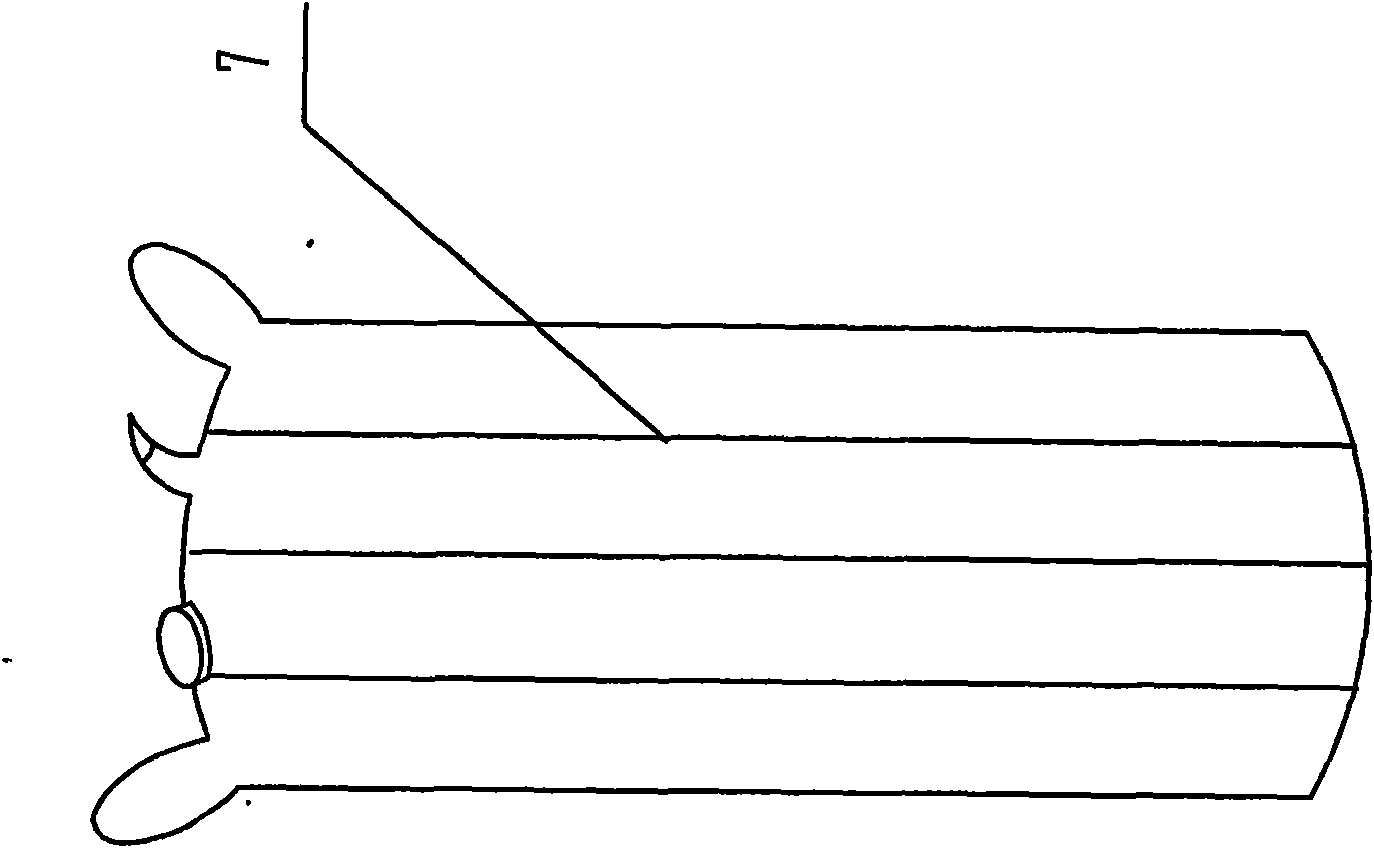

[0012] The rubber water injection mold body 1 is processed with reinforcing ribs 7, and the bottom of the rubber water injection mold body 1 is processed into a slightly arc or flat bottom.

[0013] When working, enter water at 4 inlets and outlets to fill the rubber water injection mandrel with water. After the workpiece is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com