Device for lifting reverse roller of loom

A technology of reverse rollers and looms, which is applied to auxiliary equipment for weaving, textiles, textiles, and papermaking. It can solve the problems of large damage to the lifting device of the reverse roller, heavy weight, and deterioration of the workability of the warp reel. Save manpower, reduce risks, and improve workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

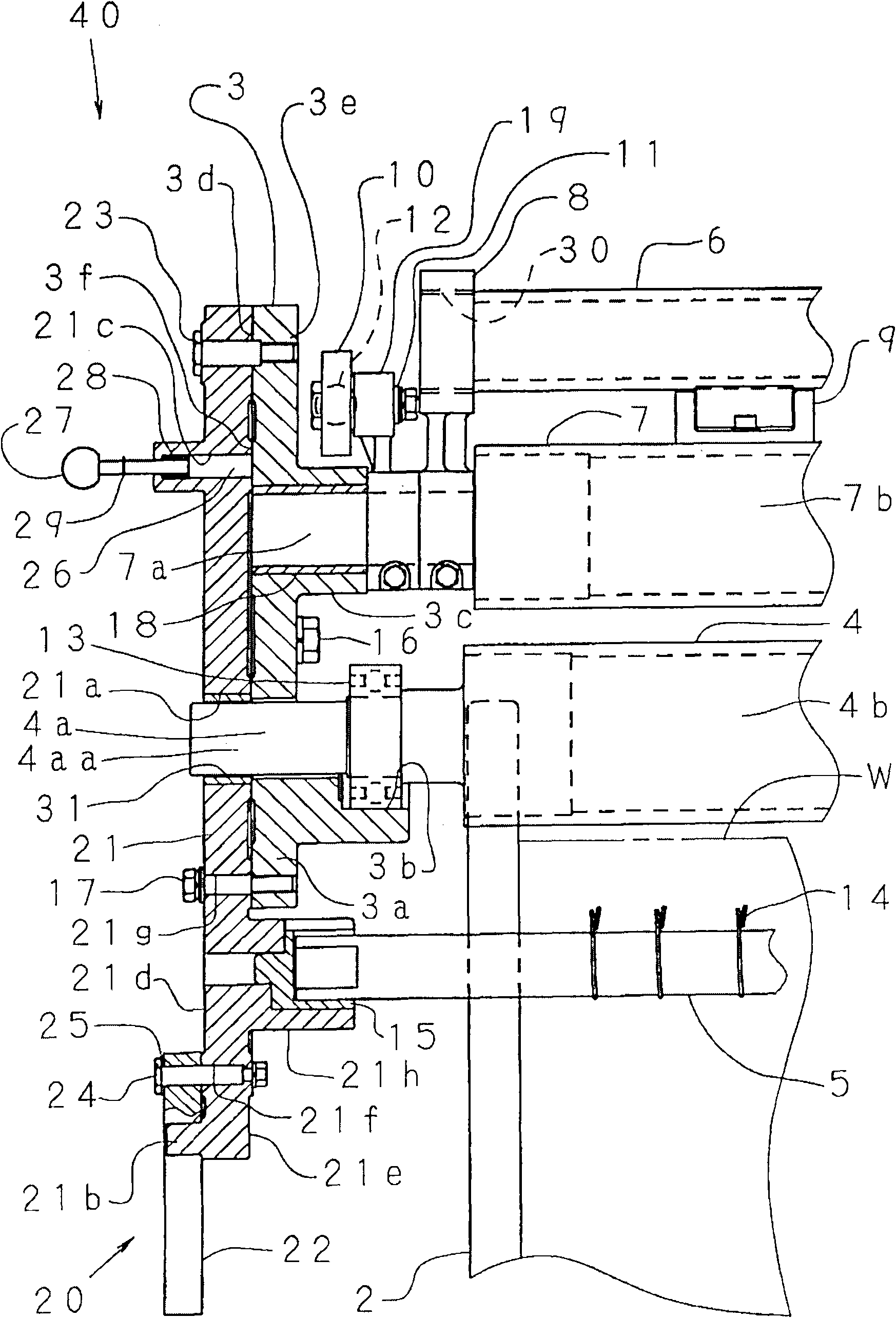

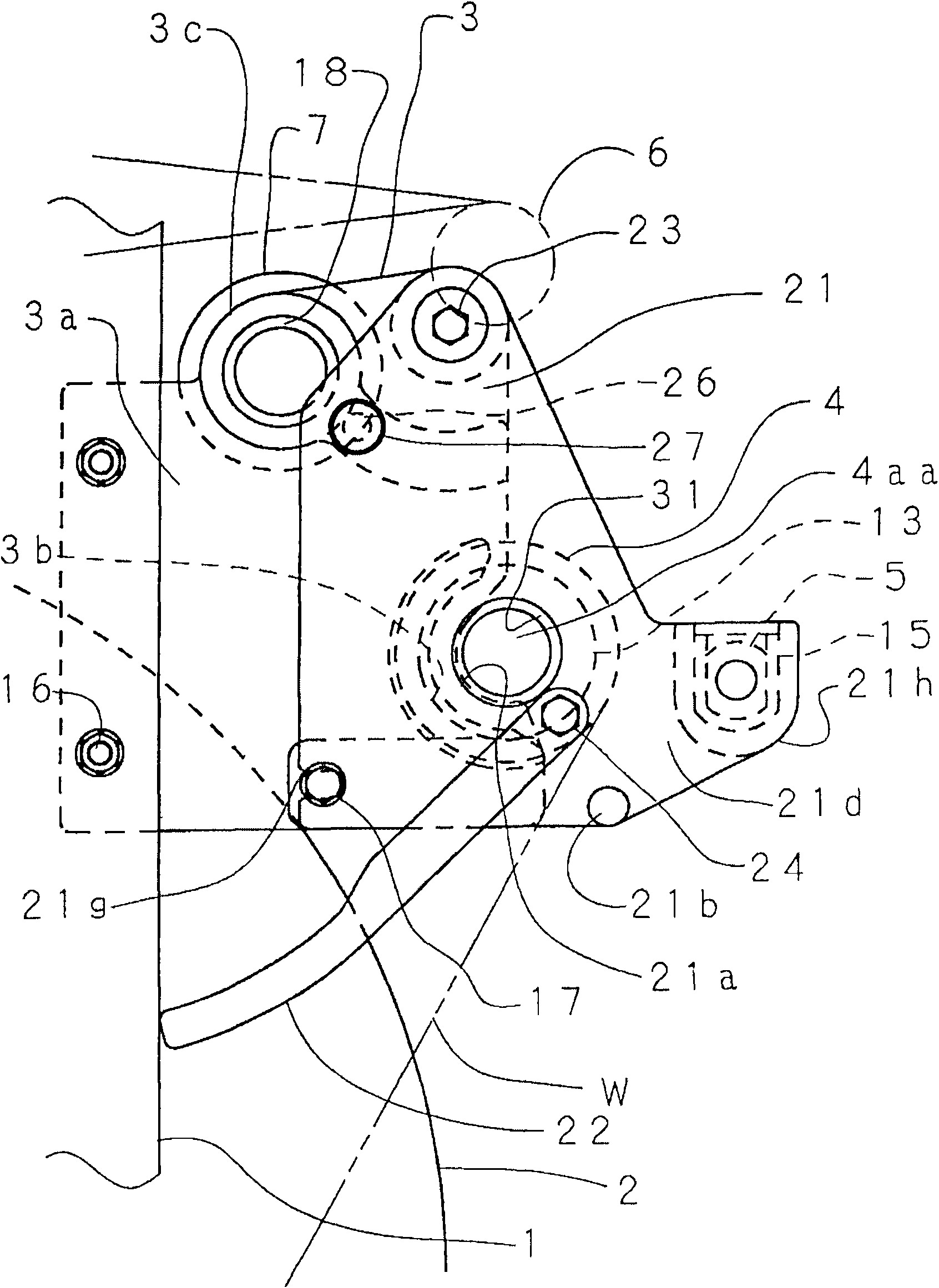

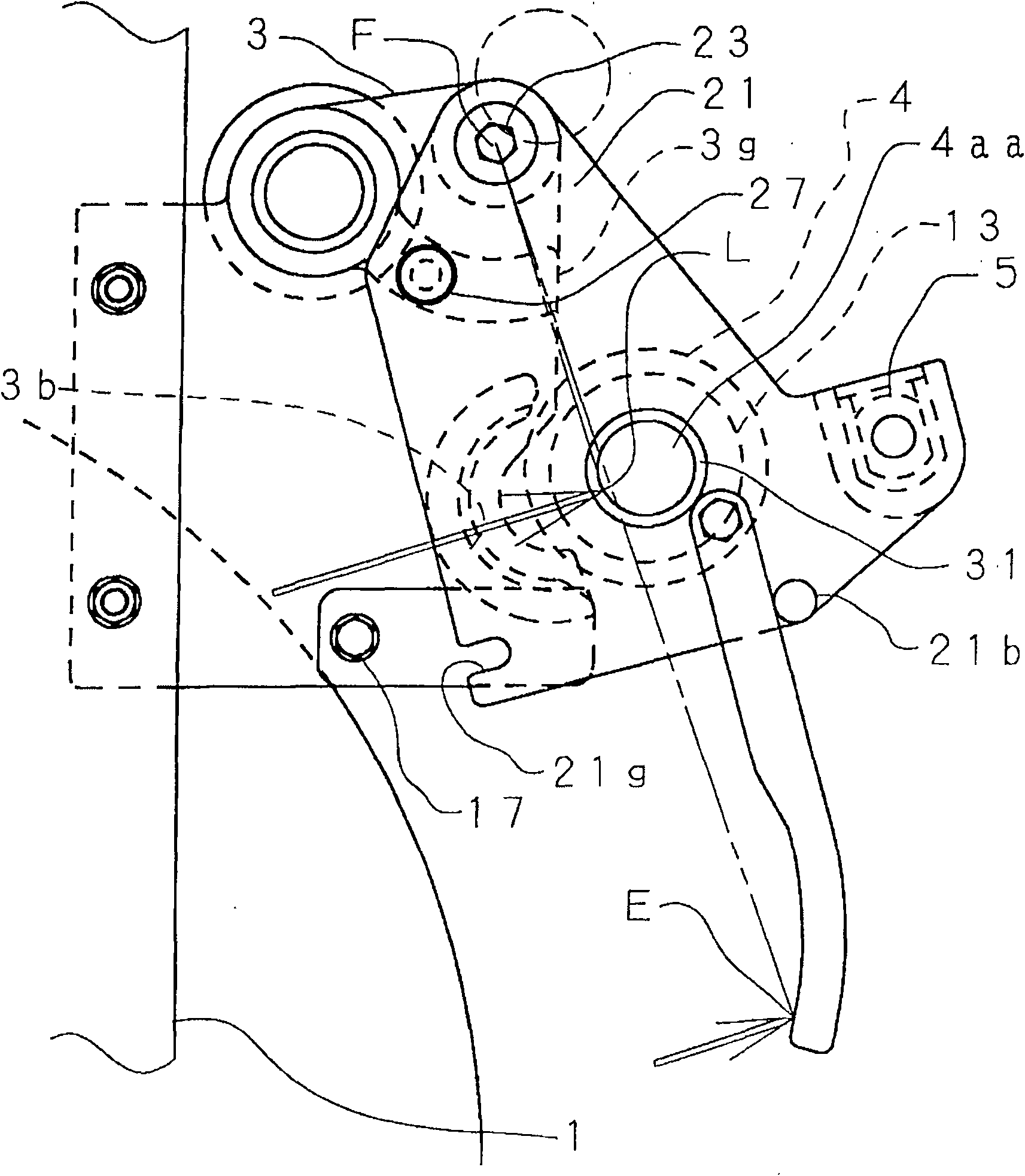

[0023] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It shows the delivery device on the right side viewed from the winding side of the loom, and shows a rear view of the reverse roller lifting device 40 of the delivery device viewed from the rear side of the loom. In addition, in order to show overlapping parts that cannot be seen, the position and shape of each part are shown in the direction perpendicular to the fabric width direction in which the reverse roller 4 extends, that is, in the front-rear direction of the loom viewed from the winding side. Appropriate changes are made to depict. figure 2 From figure 1The side view seen on the left side of , shows the counter roll lifting device 40 in operation of the loom. except not depicted figure 1 Shown end support 8, middle part support 9, spherical surface bearing unit 10, loosening distribution pin 11, loosening warp bar 12, outside loosening warp lever 19, depict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com