Spiral wound film element

A roll-type membrane and element technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of low membrane utilization rate, low effective membrane area, and low water production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

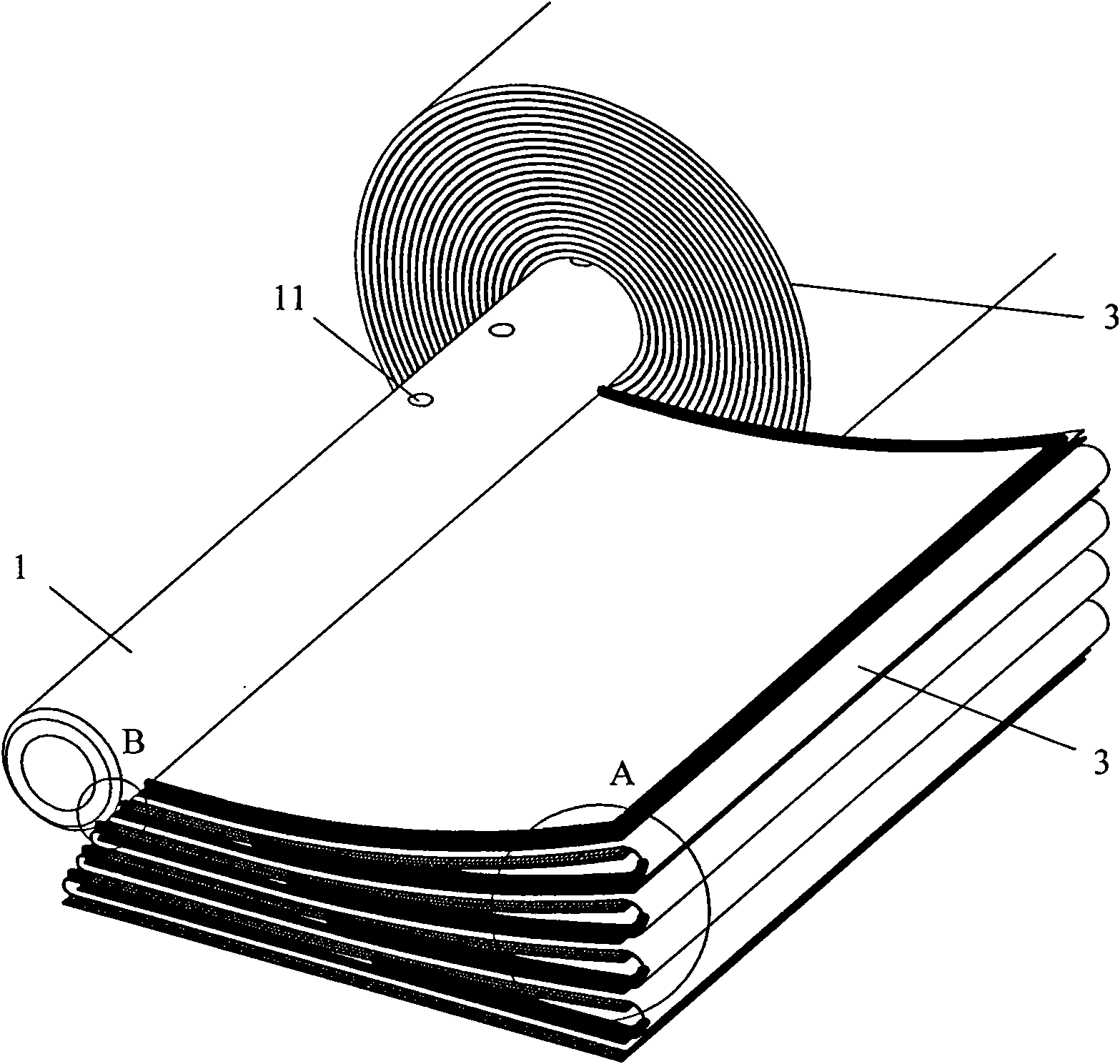

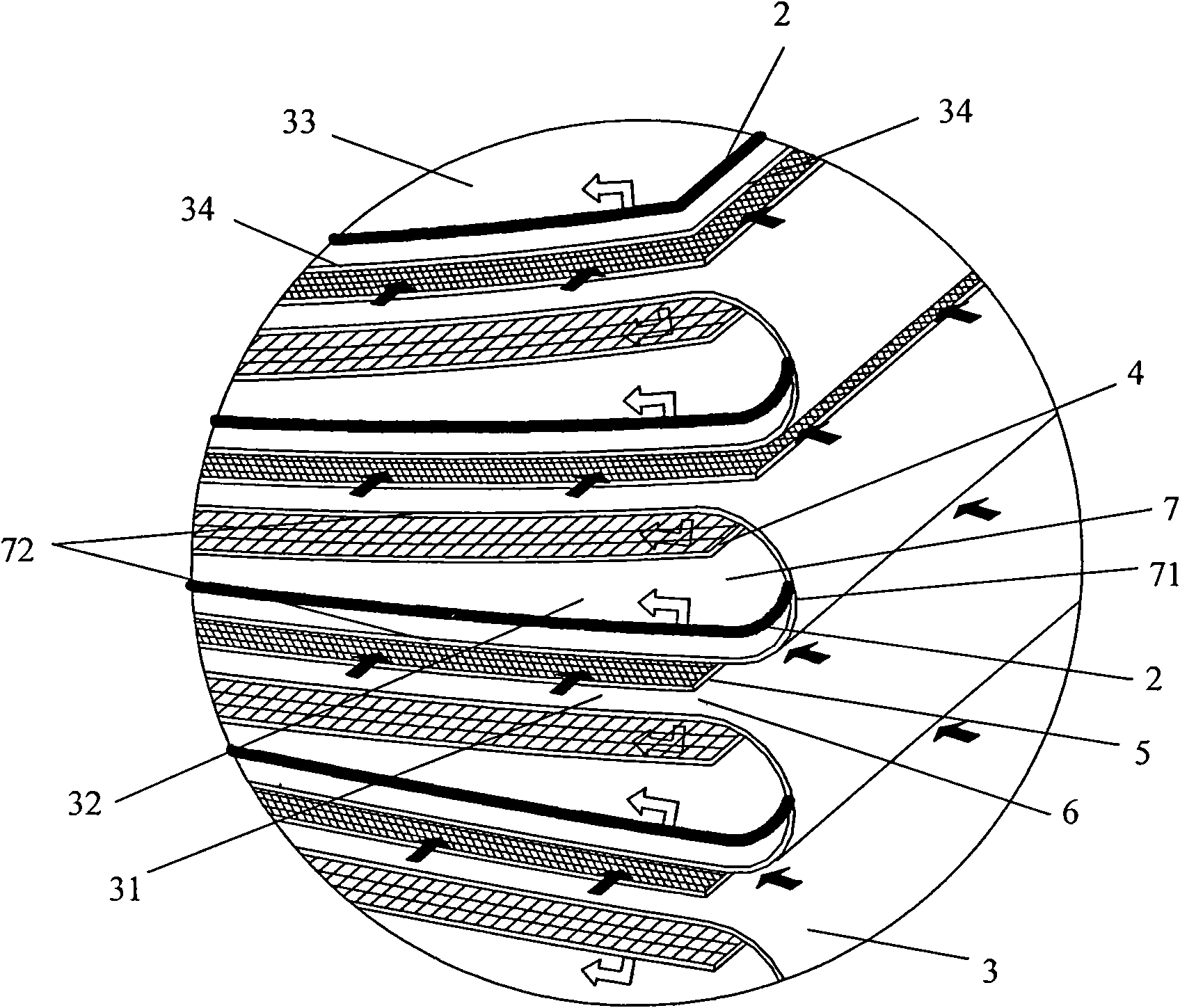

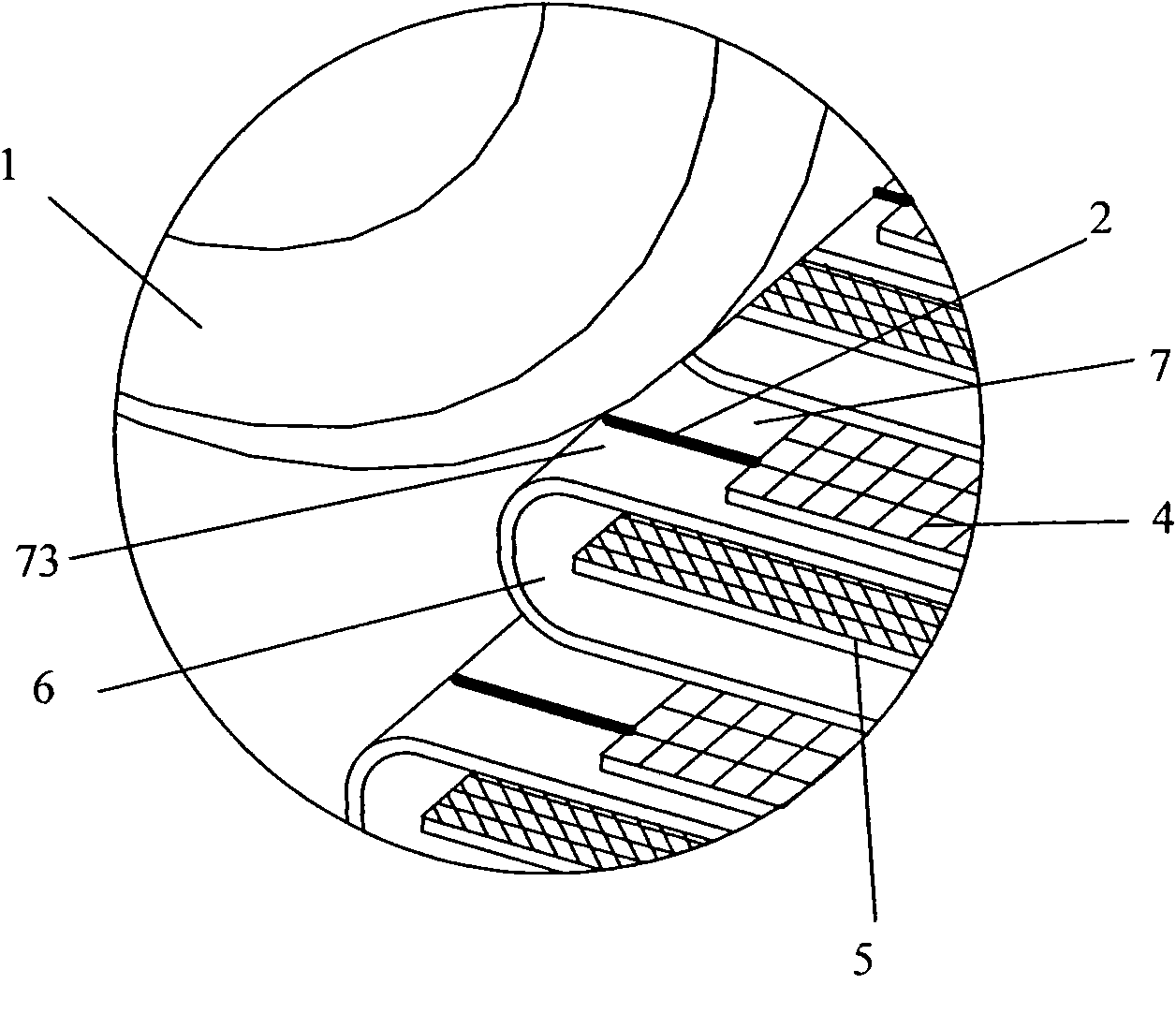

[0020] Such as figure 1 and combine figure 2 , image 3 As shown, the spiral-wound membrane element of the present invention includes a central water collection pipe 1 , a sealant 2 , a separation membrane 3 , a water production guide cloth 4 , and an inlet water guide cloth 5 .

[0021] The central water collecting pipe 1 is a hollow pipe with seepage holes 11 communicated with the inside on its surface. The separation membrane 3 is an uncut membrane, folded repeatedly to form a plurality of alternately arranged water inlet interlayers 6 formed by the front 31 of the separation membrane and water production interlayers 7 formed by the back 32 of the separation membrane. The water inlet guide cloth 5 is inserted in the water inlet interlayer 6 , and the water production guide cloth 4 is inserted in the water production interlayer 7 . The front and rear sides 72 of the water-producing interlayer 7 adjacent to the folded edge 71 are sealed by the sealant 2 so that the water-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com