Complete waste cleaning rotary die cutting machine

A die-cutting machine and round-pressing technology, which is applied in the field of waste-clearing round-pressing die-cutting machines, can solve problems such as troublesome production, high mechanical noise of chip shakers, and increased labor costs, so as to reduce operating costs of enterprises and clean production Environment, the effect of reducing the cost of labor use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

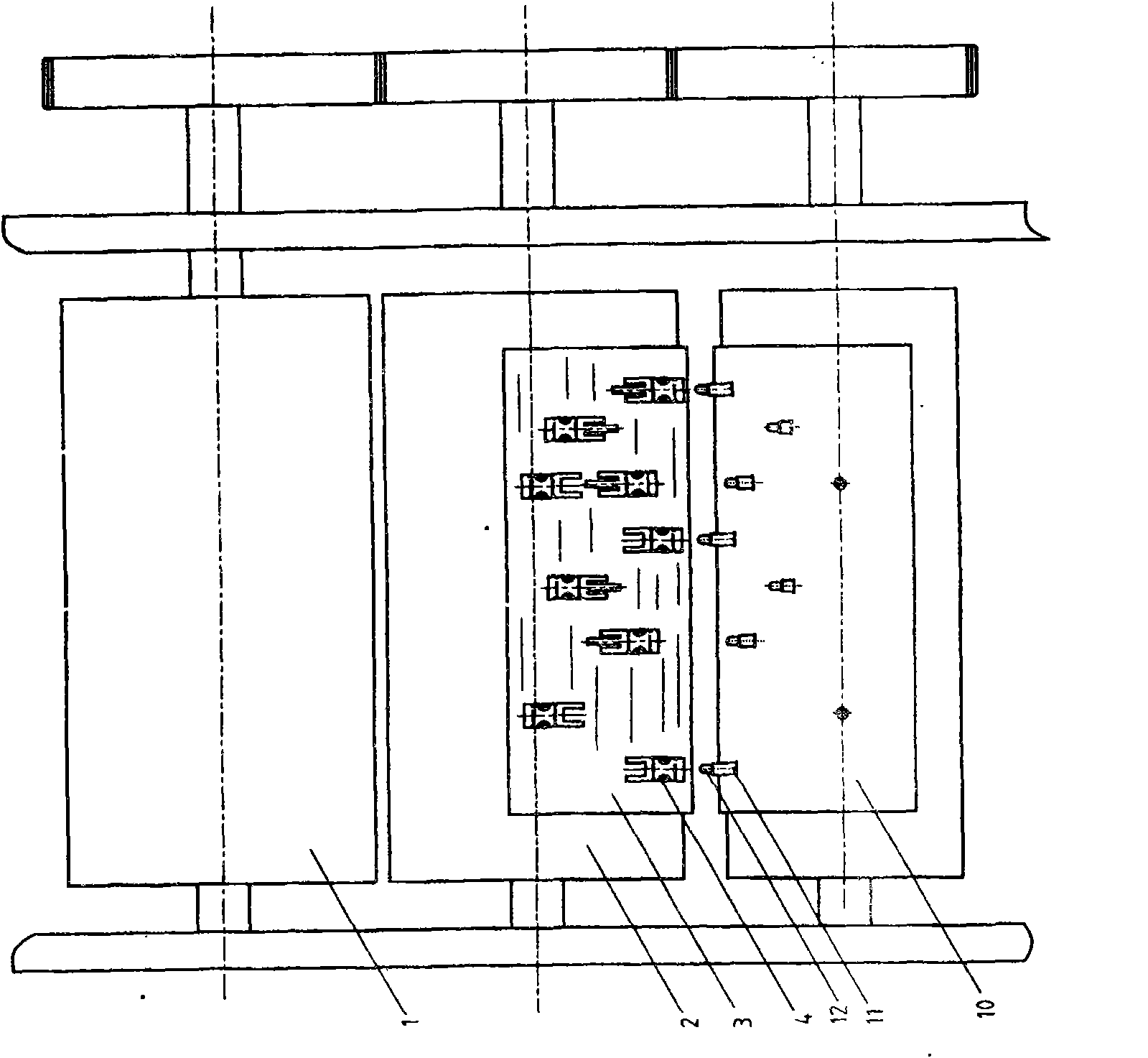

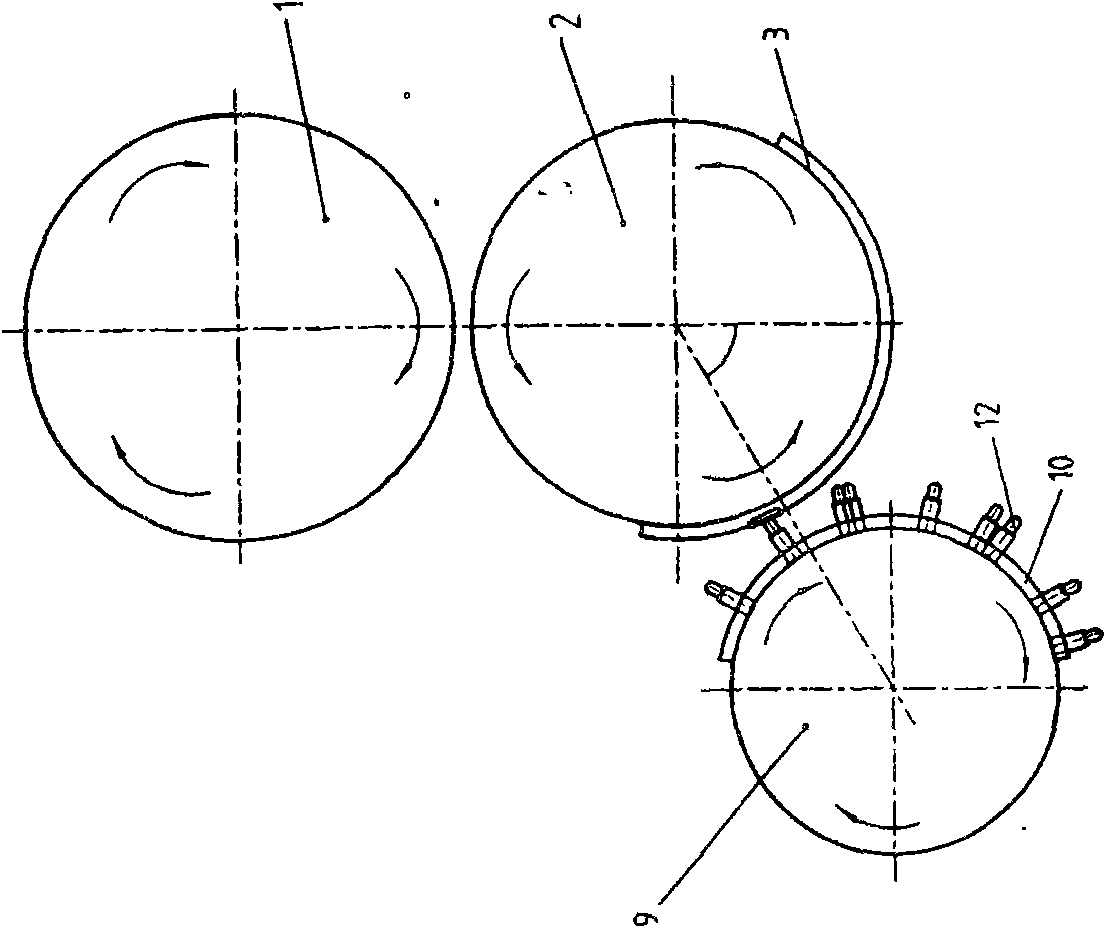

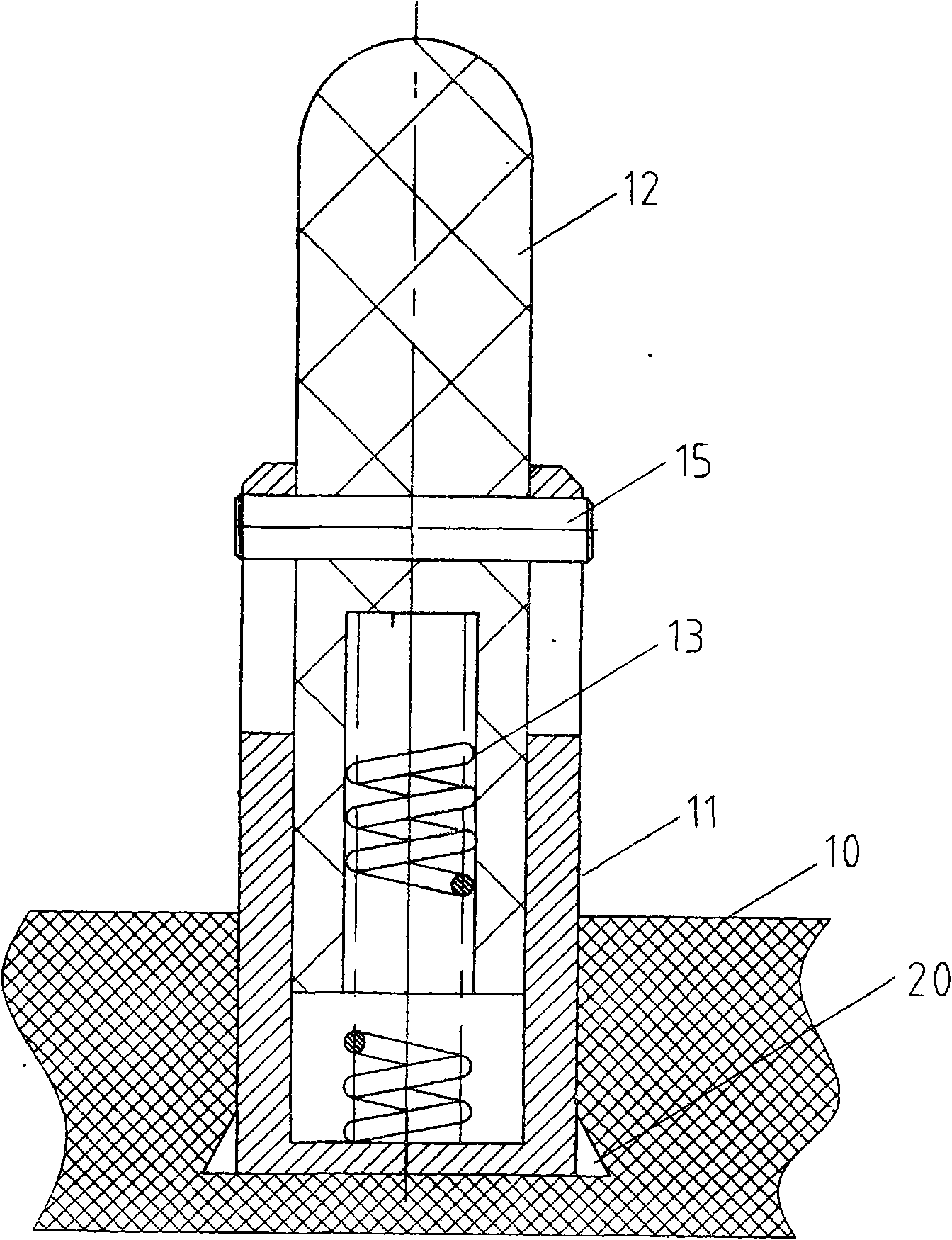

[0031] As shown in the figure, a full cleaning waste circular die cutting machine is composed of a rubber roller 1, a die cutting plate roller 2 and a knife plate 3, and a waste stripping component corresponding to each piece of die cutting waste is arranged on the knife plate 3 4. The stripping member 4 grasps the waste and rotates with the knife plate 3. A stripping roller 9 is set on the rear or front of the die-cutting plate roller 2, and a strip corresponding to the stripping component 4 is arranged on the stripping roller 9. The stripping contact 12, the stripping roller 9 and the die-cutting plate roller 2 rotate at the same speed, and the direction is opposite. Each stripping contact 12 is in contact with the corresponding stripping member 4 when the roller distance is the closest. When the contacts 12 come into contact with the stripping member 4, the stripping member 4 releases the waste material it has seized. On the same section of the rubber roller 1, the die-cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com