Drill of high pressure water jet long screw pile driver

A technology of high-pressure water jet and long helix, which is applied in the direction of drill bit, sheet pile wall, drilling equipment, etc., can solve the problems of drill bit not being able to continue drilling, drill bit wear, delay of construction period, etc., to achieve optimal control and utilization, low piling cost, The effect of fast piling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

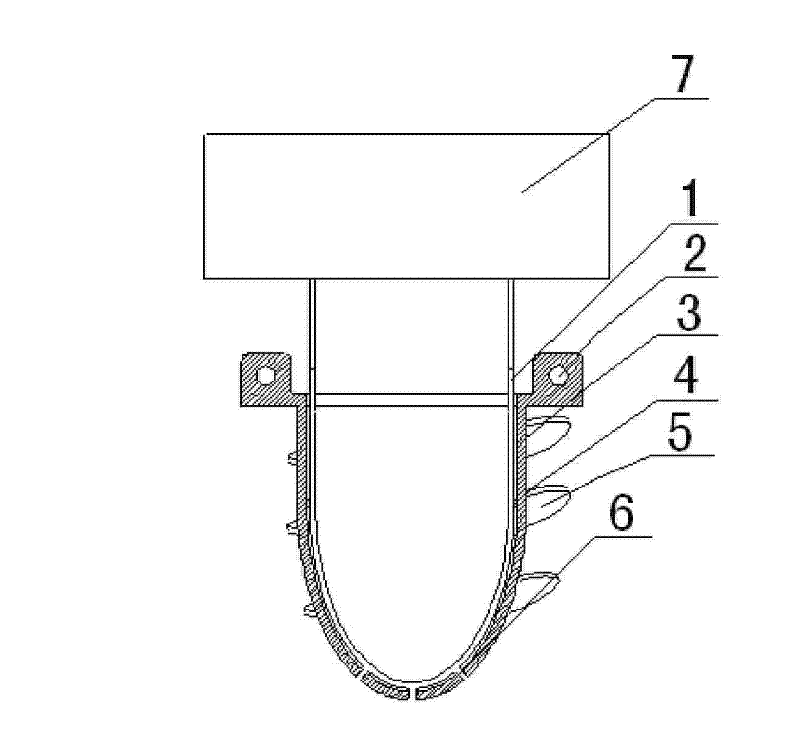

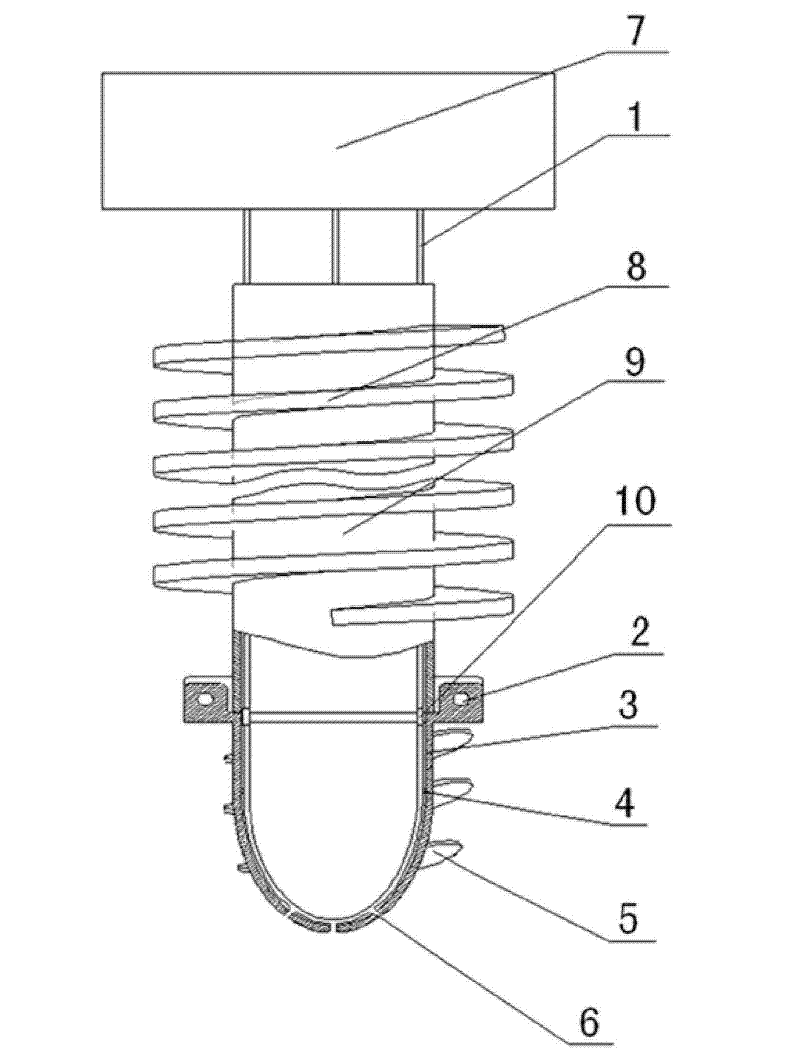

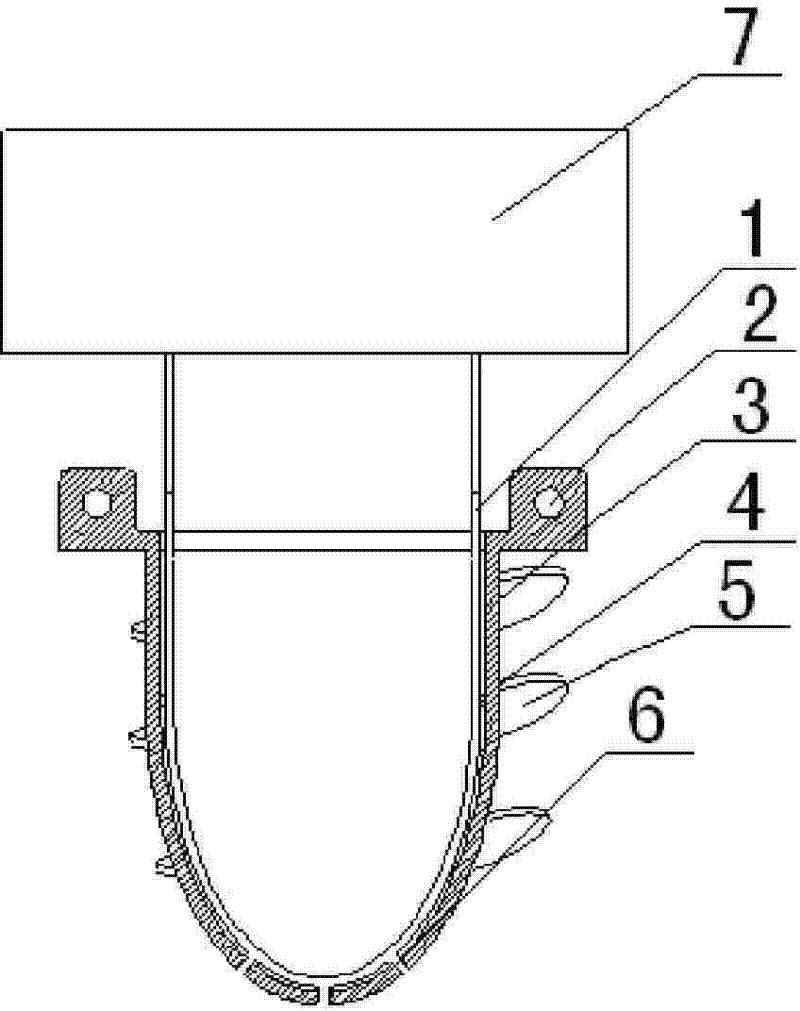

[0014] refer to figure 1 , 2 , this embodiment includes a drill body 3, a high-pressure water jet conduit 1, and a high-pressure water jet generation and control device 7. The high-pressure water jet conduit 1 is fixed to the hollow long screw rod and the inner wall of the drill bit body 3 through a conduit fixing clip 4, and the hollow The high-pressure water jet conduit in the long screw rod is connected to the high-pressure water jet conduit in the drill body 3 through a high-pressure resistant hose 10, and the high-pressure water jet conduit in the drill body 3 is connected to the nozzle 6 at the front end of the drill body 3, and the nozzle 6 The water jet spray holes should be evenly distributed on the side wall and top of the drill bit front end; the outer surface of the drill bit body 3 side walls are evenly distributed with blades 5; fixed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com