Feeder for automatic assembling machine

A supply device and automatic assembly technology, applied in the direction of electrical components, electrical components, etc., to achieve the effect of high-precision positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

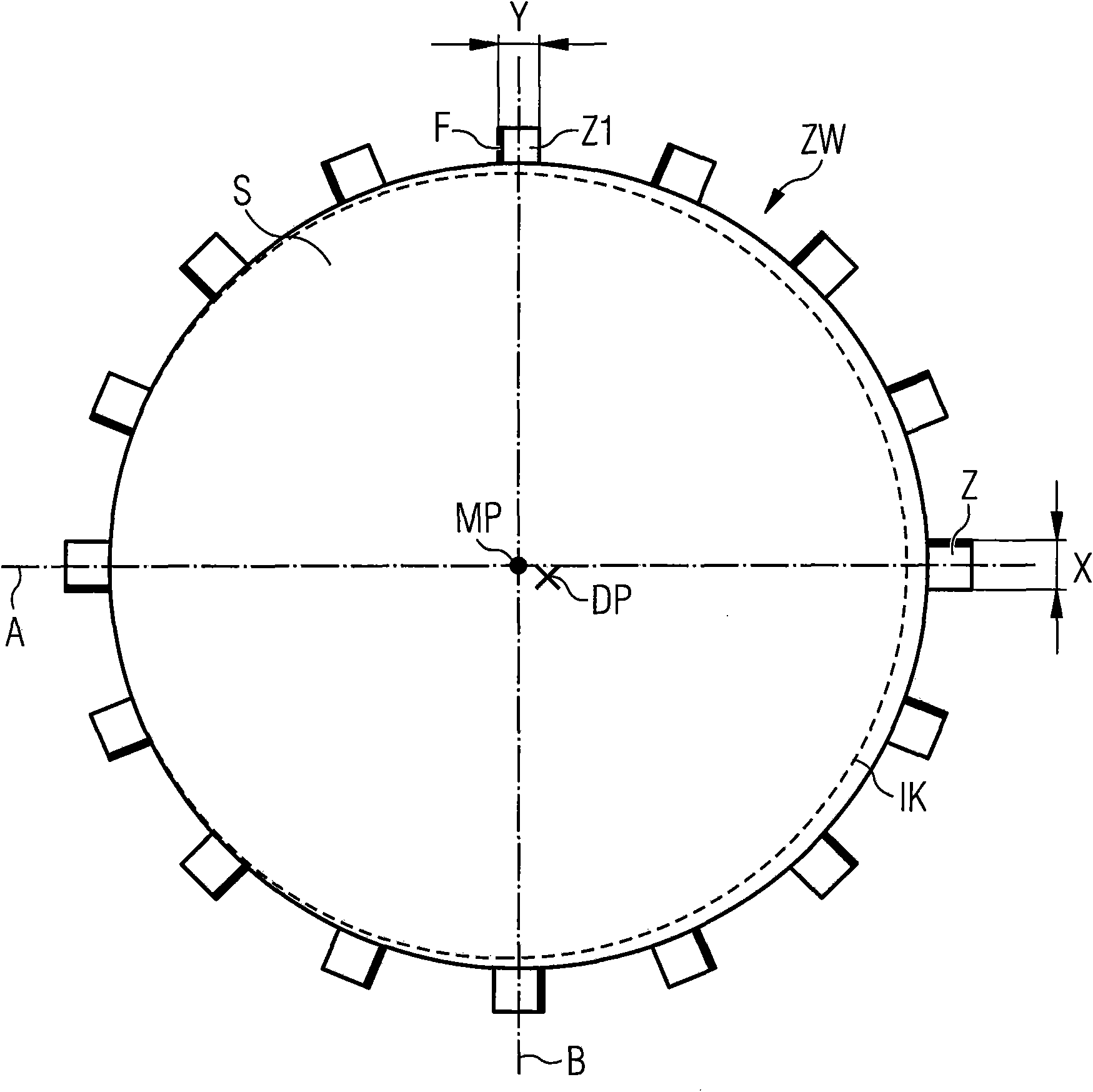

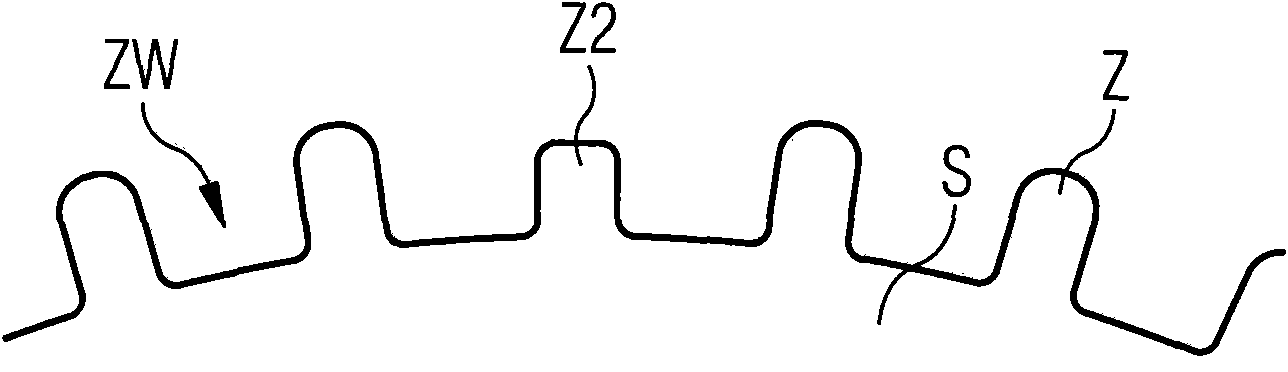

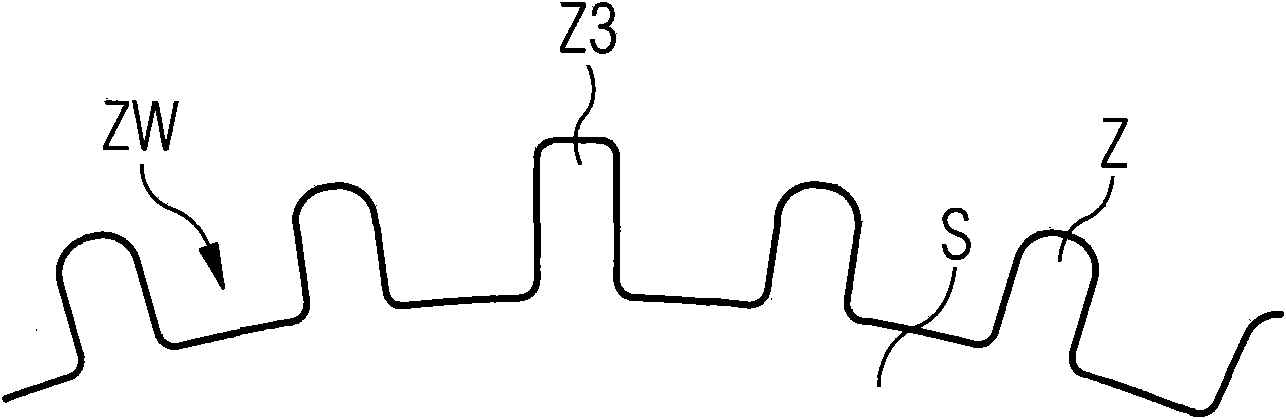

[0028] figure 1 A pin wheel S is shown in a schematic and exemplary manner, which can be used in particular in feeding devices for automatic assembly machines. The pinwheel S has pinwheel teeth Z evenly distributed over the circumference, which are separated by gaps ZW. The pinwheel tooth Z has a width X and a front side F from which the component conveyor belt continues to be conveyed, for example when using the pinwheel S in a feeding device for an automatic assembly machine.

[0029] The pin wheel S is movable around the center of rotation DP. This center of rotation DP may, for example, deviate from the geometric center MP, ie the intersection of lines A and B, due to manufacturing processes. Likewise, for example, the pin wheel S itself may deviate from the ideal circular shape IK due to the manufacturing process. These deviations due to the manufacturing process of the pin wheel S (also referred to as manufacturing tolerances) have a negative effect, especially in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com