Calcium acetate tablet and preparation method thereof

A technology of calcium acetate and magnesium stearate, which can be applied to pharmaceutical formulations, medical preparations with inactive ingredients, anhydride/acid/halide active ingredients, etc. The problem of large dosage, etc., achieves the effect of safe and effective treatment of hyperphosphatemia, shortened disintegration time and convenient administration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

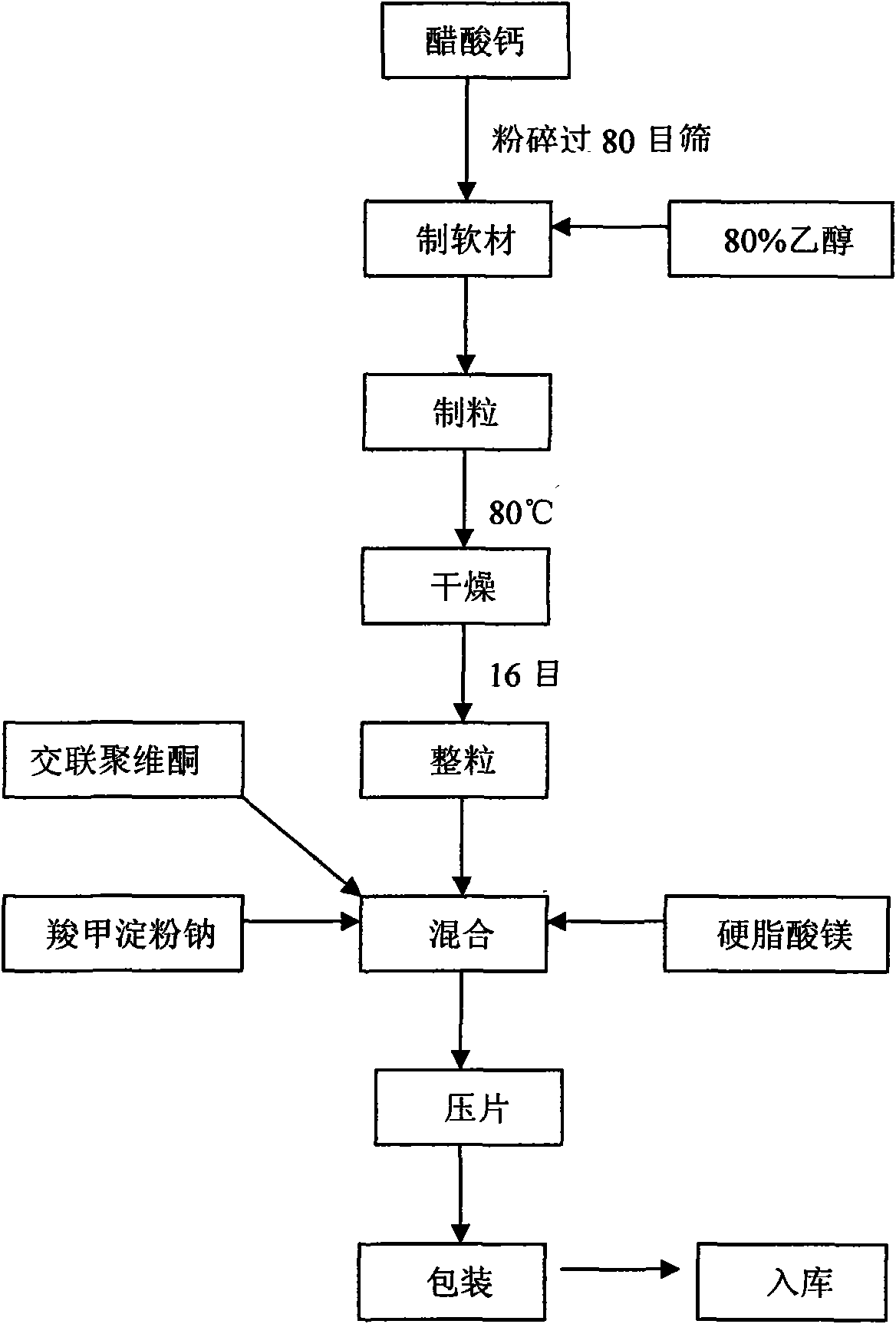

Method used

Image

Examples

Embodiment 1

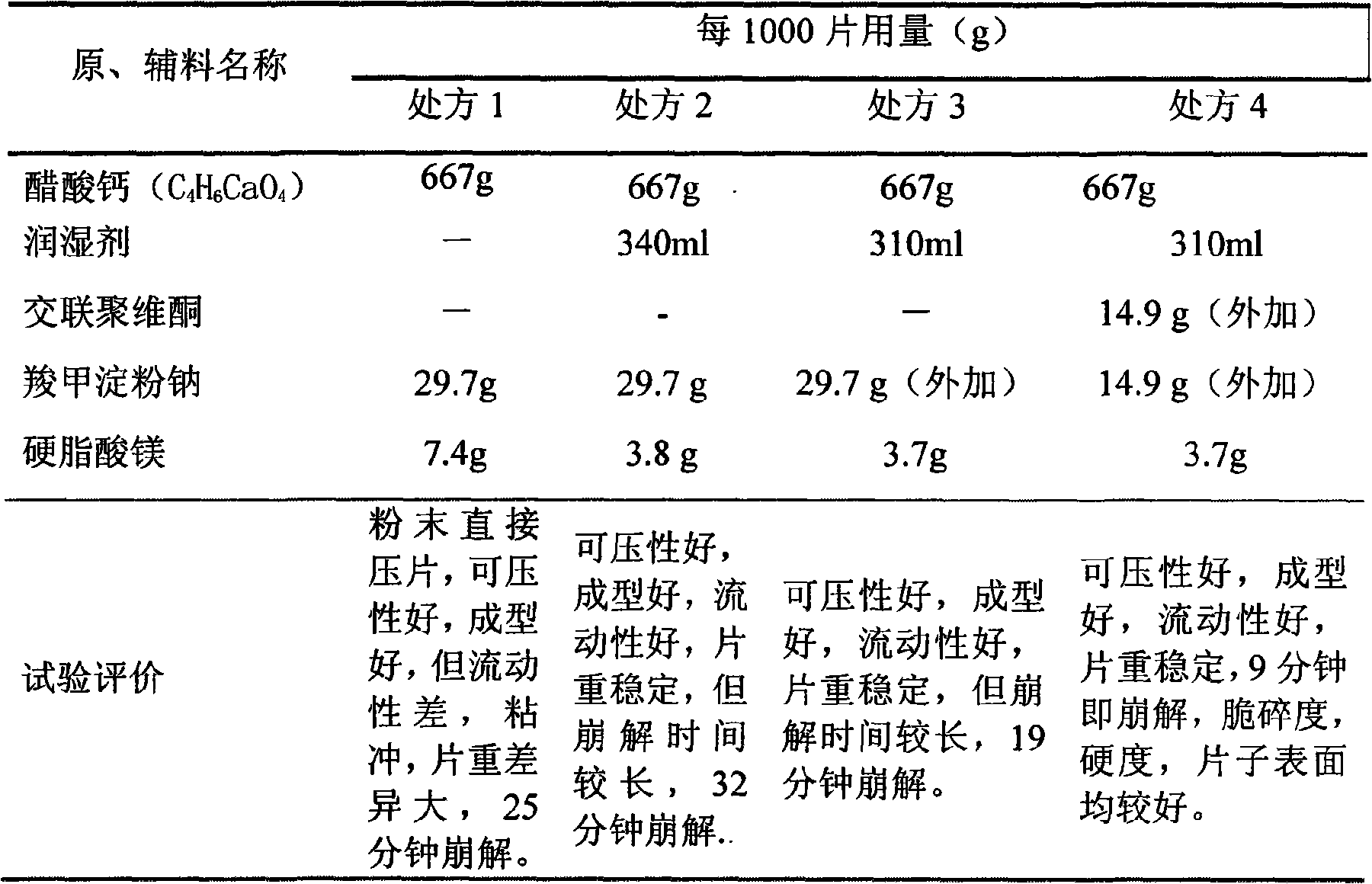

[0028] Calcium acetate (C 4 h 6 CaO 4 ) 667g (91.36%)

[0029] Sodium Starch Carboxymethyl 35g (4.75%)

[0030] Crospovidone 25g (3.39%)

[0031] Magnesium Stearate 10g (1.36%)

[0032]

[0033] Makes 1000 pieces

[0034] Preparation method:

[0035] a. Calcium acetate is pulverized through a 60-mesh sieve for subsequent use;

[0036] b. Prepare 50% ethanol for subsequent use;

[0037] c. Take the calcium acetate of recipe quantity and put in the fast mixing granulator, add 50% ethanol in right amount, make soft material, cross 10 mesh sieves and granulate;

[0038] d. Set the drying temperature to 50°C, and dry the wet granules in a hot air circulation oven or common drying equipment until the moisture content is lower than 5%;

[0039] e. Sieve the dry granules through 16 sieves, add sodium starch glycolate, crospovidone and magnesium stearate, and mix in a mixer for 7 minutes;

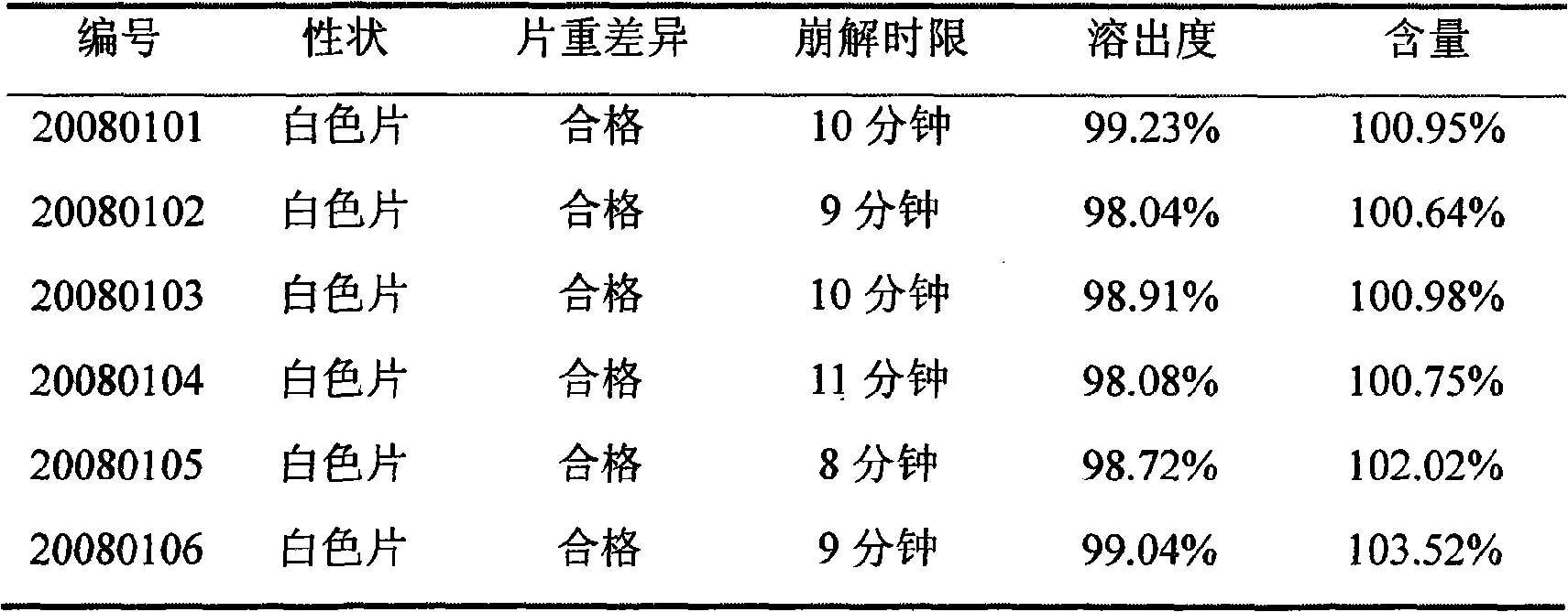

[0040] f. Measure the main drug co...

Embodiment 2

[0043] Calcium acetate (C 4 h 6 CaO 4 ) 667g (95.68%)

[0044] Sodium starch glycolate 14.9g (1.92%)

[0045] Crospovidone 14.9g (1.92%)

[0046] Magnesium Stearate 3.7g (0.48%)

[0047]

[0048] Makes 1000 pieces

[0049] Preparation method:

[0050] a. Calcium acetate is pulverized and sieved through 80 sieves for subsequent use;

[0051] b. Prepare 80% ethanol for subsequent use;

[0052] c. take the calcium acetate of recipe quantity and put in the fast mixing granulator, add 80% ethanol in right amount, make soft material, cross 16 mesh sieves and granulate;

[0053] d. Set the drying temperature to 75°C, and dry the wet granules in a hot air circulation oven or common drying equipment until the moisture content is lower than 5%;

[0054] e. Pass the dry granules through a 16-mesh sieve for granulation, add sodium starch glycolate, crospovidone and magnesium stearate, and mix in a mixer for 10 minutes;

[005...

Embodiment 3

[0058] Calcium acetate (C 4 h 6 CaO 4 ) 667g (96.95%)

[0059] Sodium carboxymethyl starch 8g (1.16%)

[0060] Crospovidone 12g (1.74%)

[0061] Magnesium Stearate 1g (0.145%)

[0062]

[0063] Makes 1000 pieces

[0064] Preparation method:

[0065] a. Calcium acetate is pulverized through a 100-mesh sieve for subsequent use;

[0066]b. Prepare 90% ethanol for subsequent use;

[0067] c. take the calcium acetate of recipe quantity and put in the fast mixing granulator, add 90% ethanol in right amount, make soft material, cross 20 mesh sieves and granulate;

[0068] d. Set the drying temperature to 90°C, and dry the wet granules in a hot air circulation oven or common drying equipment until the moisture content is lower than 5%;

[0069] e. Sieve the dry granules through a 20-mesh sieve, add sodium starch glycolate, crospovidone and magnesium stearate, and mix in a mixer for 15 minutes;

[0070] f. Measure the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap