Knitting needle combination

A technology of knitting needles and latch needles, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of affecting normal knitting, pushing back of needle heels, and difficulty in ensuring the reliability of knitting quality, so as to achieve accurate knitting action reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention and its advantages will be further described below in conjunction with the accompanying drawings and embodiments.

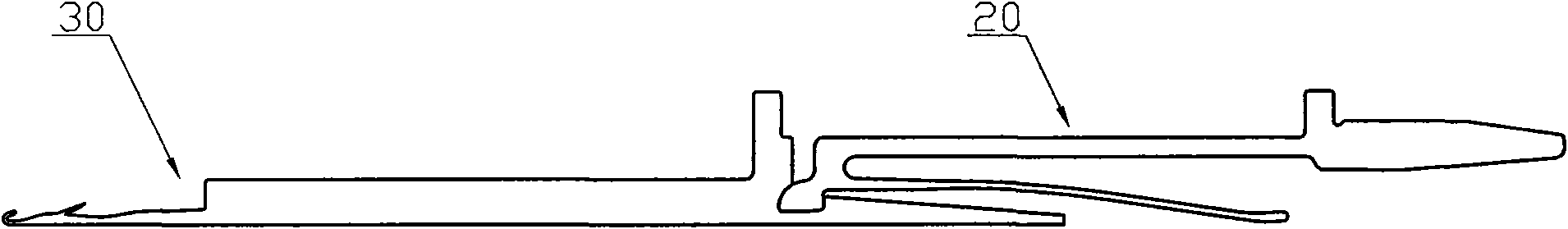

[0026] control figure 1 , The knitting needle combination of the present invention is made up of latch needle 30 and needle jack 20. Wherein the structure of the needle jack 20 and the latch needle 30 can be found in figure 2 , image 3 .

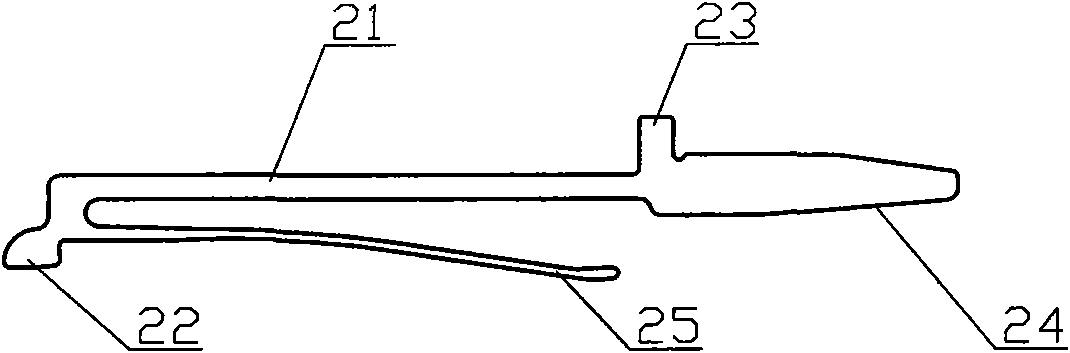

[0027] control figure 2 , The upper side of the base body 21 of the needle jack 20 is provided with a rear butt 23 for being pushed against by the knitting cam. An elastic rod 25 is provided on the lower side of the base body 21, and the front end of the lower side of the base body 21 is provided with an embedding part 22, and the rear part is provided with an electromagnetic engaging surface 24, please refer to figure 2 .

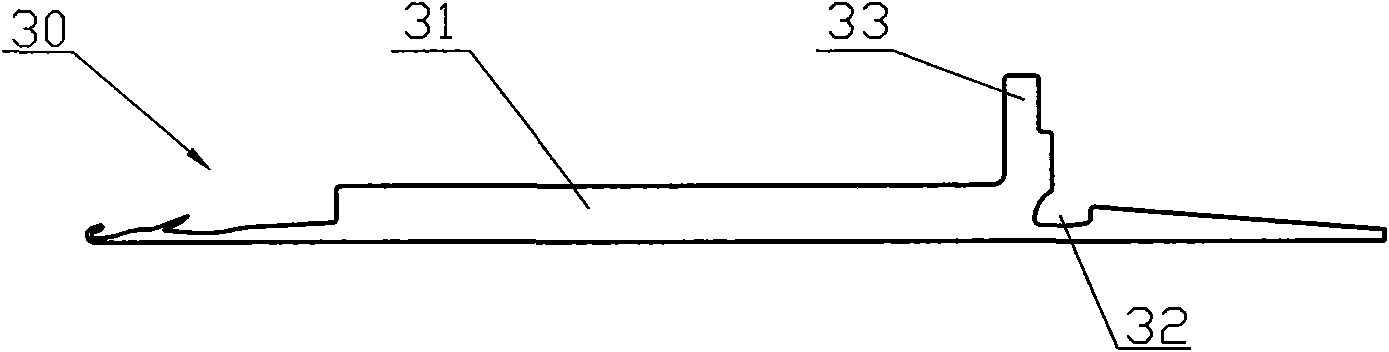

[0028] control image 3 A front butt 33 for being pushed against by the knitting cam is provided on the upper side of the needle body 31 of the latch needle, and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com