Integrated module of automobile engine thermostat seat and engine oil filter seat

A technology for oil filter and automobile engine, which is applied to engine components, machine/engine, engine cooling, etc., can solve the problems of thick thermostat seat, easy breakage of installation bosses, and increased parts scrap rate, etc. Concentration of oil channels and water channels, which is conducive to compact layout and the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

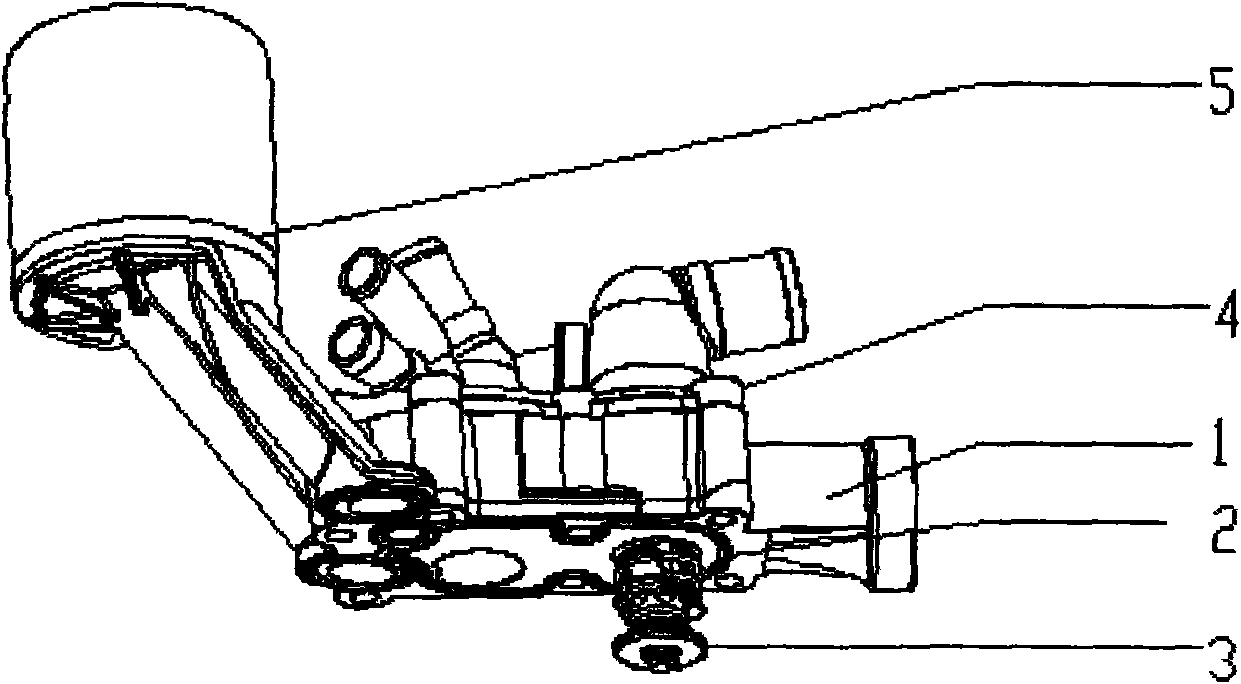

[0020] like figure 1 As shown, the thermostat seat and the oil filter seat are integrated into one module.

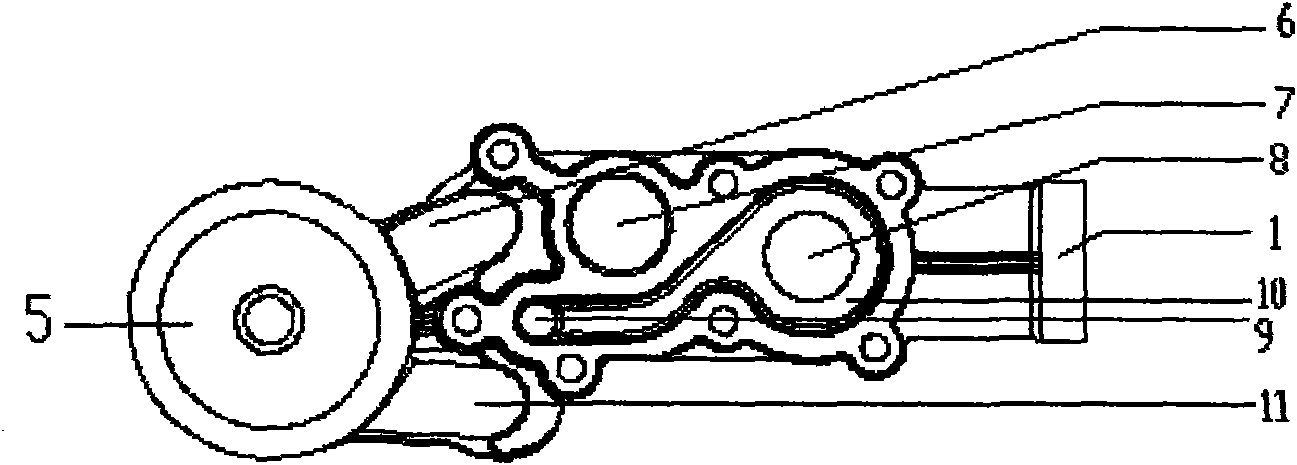

[0021] like figure 2 As shown, the bottom of the module is provided with an oil passage 6 and an oil passage 11, and the two oil passages communicate with the oil filter 5, wherein the oil passage 6 communicates with the main oil passage of the engine.

[0022] like figure 1 As shown, the top of the module is connected with a thermostat cover 4, and the large and small circulation water inlets and outlets on the thermostat cover communicate with the thermostat in the module.

[0023] like figure 1 , figure 2 As shown, the side of the module is connected with a water pipe joint 1.

[0024] like figure 2 As shown, the bottom of the module is provided with the first water inlet 9 of the thermostat, which is connected to the outlet pipe of the oil cooler. The bottom of the module is provided with the second water inlet 7 of the thermostat, and the water inlet is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com