Control device for working vehicle

A technology for control devices and engineering vehicles, which is applied in the direction of control devices, electrical controls, vehicle components, etc., and can solve the problems of large pump discharge, large heat energy loss, and large pressure oil overflow, so as to suppress overflow and reduce heat. The effect of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

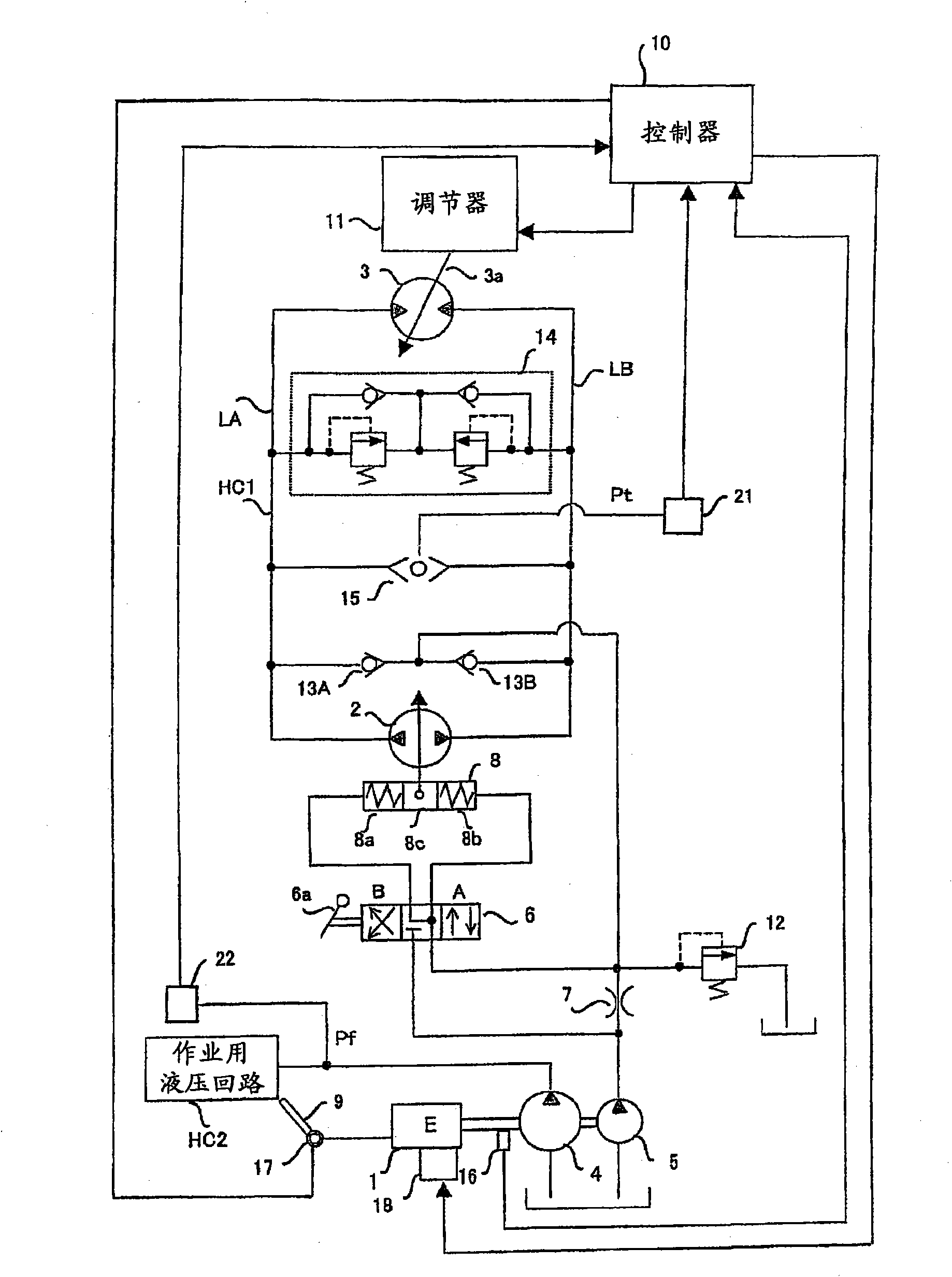

[0027] Below, refer to Figure 1 to Figure 8 A first embodiment of the control device for a construction vehicle according to the present invention will be described.

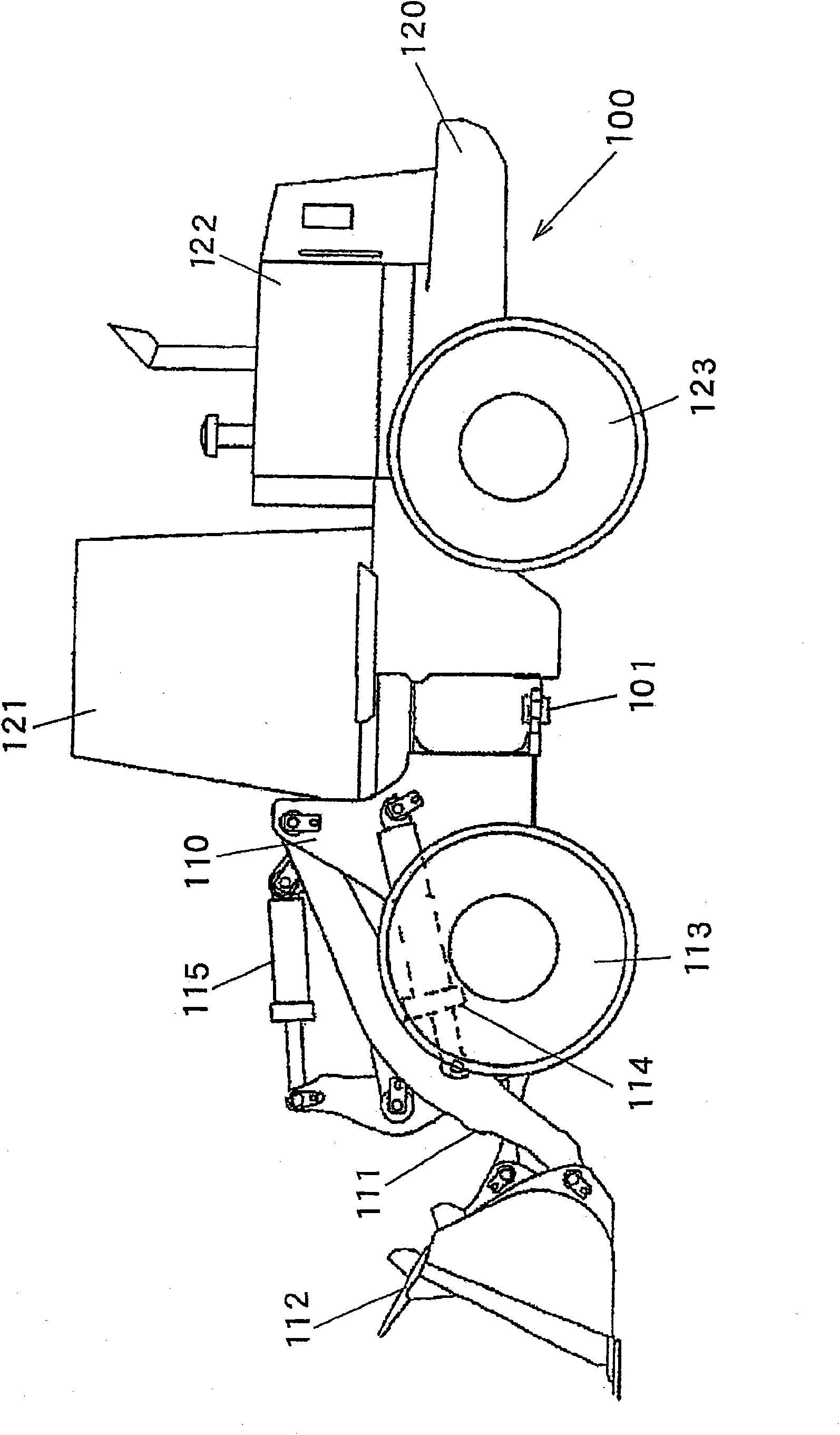

[0028] figure 1 It is a side view of a wheel loader which is an example of a construction vehicle to which the travel control device according to this embodiment is applied. The wheel loader 100 is composed of a front body 110 having an arm 111 , a bucket 112 , wheels 113 , and the like, and a rear body 120 having a cab 121 , an engine room 122 , wheels 123 , and the like. The arm 111 is driven by the arm hydraulic cylinder 114 to rotate in the vertical direction (pitch motion), and the bucket 112 is driven by the bucket hydraulic cylinder 115 to rotate in the vertical direction (unloading or shoveling). The front body 110 and the rear body 120 are rotatably connected to each other by a center pin 101 , and the front body 110 is bent left and right relative to the rear body 120 by expansion and contraction of...

no. 2 approach

[0057] refer to Figure 9 ~ Figure 11 A second embodiment of the control device for a construction vehicle according to the present invention will be described.

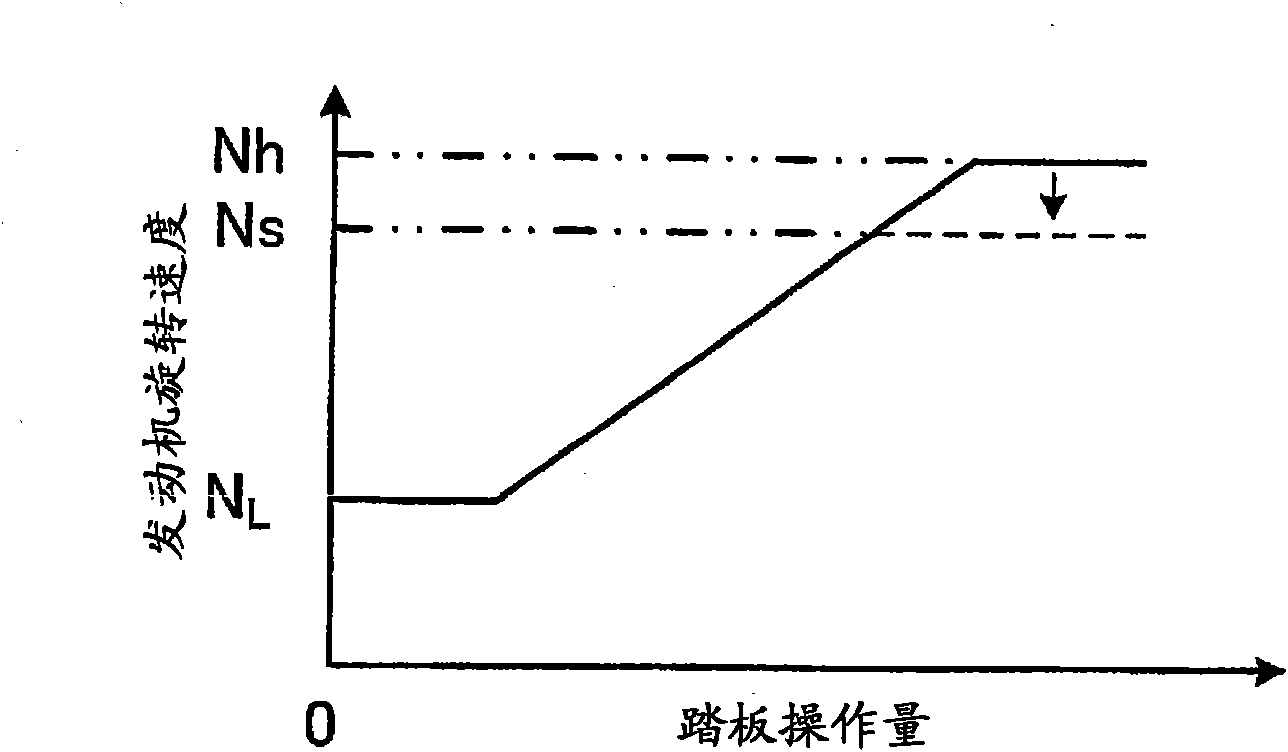

[0058] The second embodiment differs from the first embodiment in the processing in the speed upper limit value setting section of the controller 10 . That is, in the first embodiment, the upper limit value Nlim of the engine rotational speed is lowered to Ns on the condition that the travel circuit pressure Pt is equal to or greater than the predetermined value Pts and the working circuit pressure Pf is equal to or greater than the predetermined value Pfs. Here, the upper limit Nlim is lowered on the condition that the depression amount of the accelerator pedal 9 is equal to or greater than a predetermined value, the vehicle speed is equal to or less than a predetermined value, and the working circuit pressure Pf is equal to or greater than a predetermined value. Hereinafter, differences from the first embodiment w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com