Combustor

A burner, gas technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of increasing product cost, high cost, lowering the lower limit of fire power adjustment, etc. The effect of strong radiating ability and raising the upper limit value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

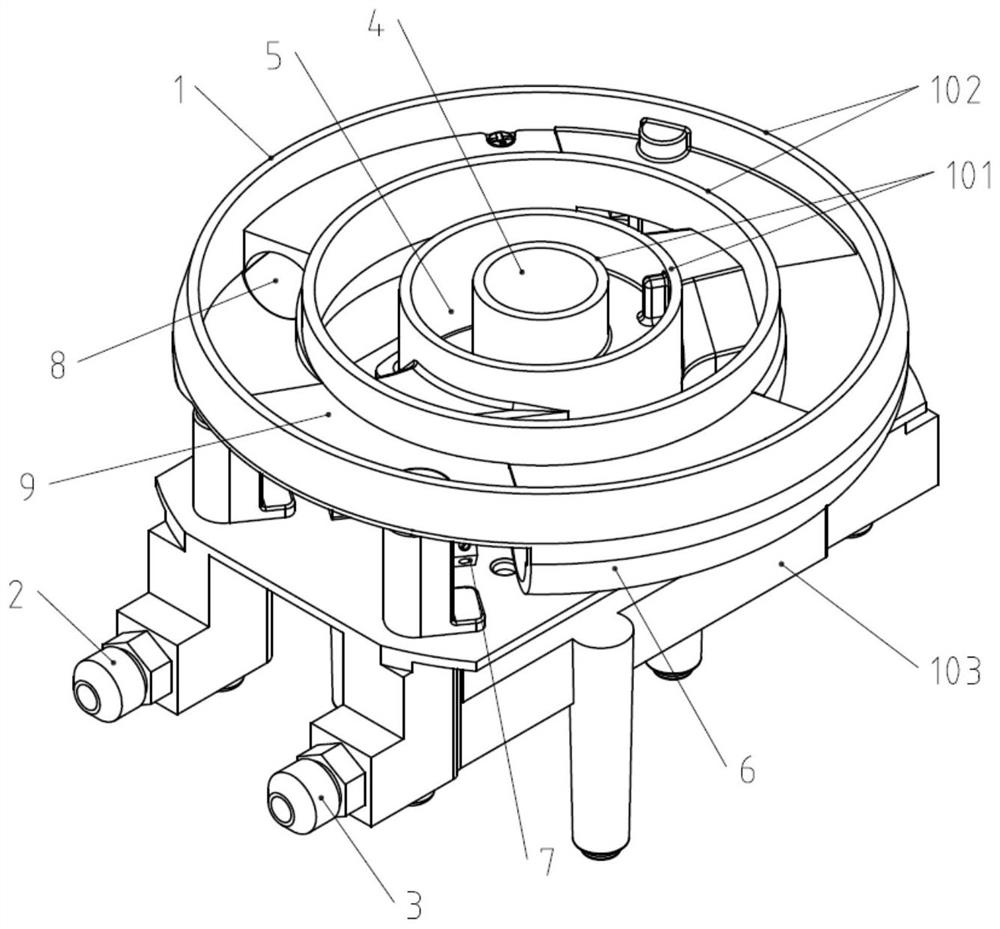

[0037] Such as Figure 1-4 The burner shown includes a burner body 1 provided with a first gas passage 2, a second gas passage 3, an inner ring gas mixing chamber 4, a middle ring gas mixing chamber 5 and an outer ring gas mixing chamber 6 .

[0038] The burner body 1 includes an inner ring body 101, an outer ring body 102 and a base 103. The outer ring body 102 surrounds the outside of the inner ring body 101. Both the inner ring body 101 and the outer ring body 102 have an outer ring wall and an inner ring wall. torus. In this implementation, the bottom of the outer ring body 102 is connected to the base 103 , of course, as other implementations, at least one of the inner ring body 101 and the outer ring body 102 may be connected to the base 103 . The first gas channel 2 and the second gas channel 3 are partly arranged in the base 103, the inner ring gas mixing channel 4 is arranged in the inner ring wall of the inner ring body 101, and the middle ring gas mixing channel 5...

Embodiment 2

[0052] Such as Figure 5-8 The burner shown is different from Embodiment 1. The burner is a down-inlet burner, including a first gas channel 2, a second gas channel 3, an inner ring gas mixing chamber 4, and a middle ring gas mixing channel. The burner body 1 of the cavity 5 and the outer ring mixed gas cavity 6 .

[0053] The burner body 1 includes an inner ring body 101 , an outer ring body 102 and a base 103 , the outer ring body 102 surrounds the inner ring body 101 , and the bottom of the outer ring body 102 and the inner ring body 101 are connected to the base 103 . Both the inner ring body 101 and the outer ring body 102 are ring bodies having an outer ring wall and an inner ring wall. The first gas passage 2 and the second gas passage 3 are arranged on the base 103, the inner ring gas mixing channel 4 is arranged in the inner ring wall of the inner ring body 101, and the middle ring gas mixing channel 5 is arranged on the inner ring of the inner ring body 101 Between...

Embodiment 3

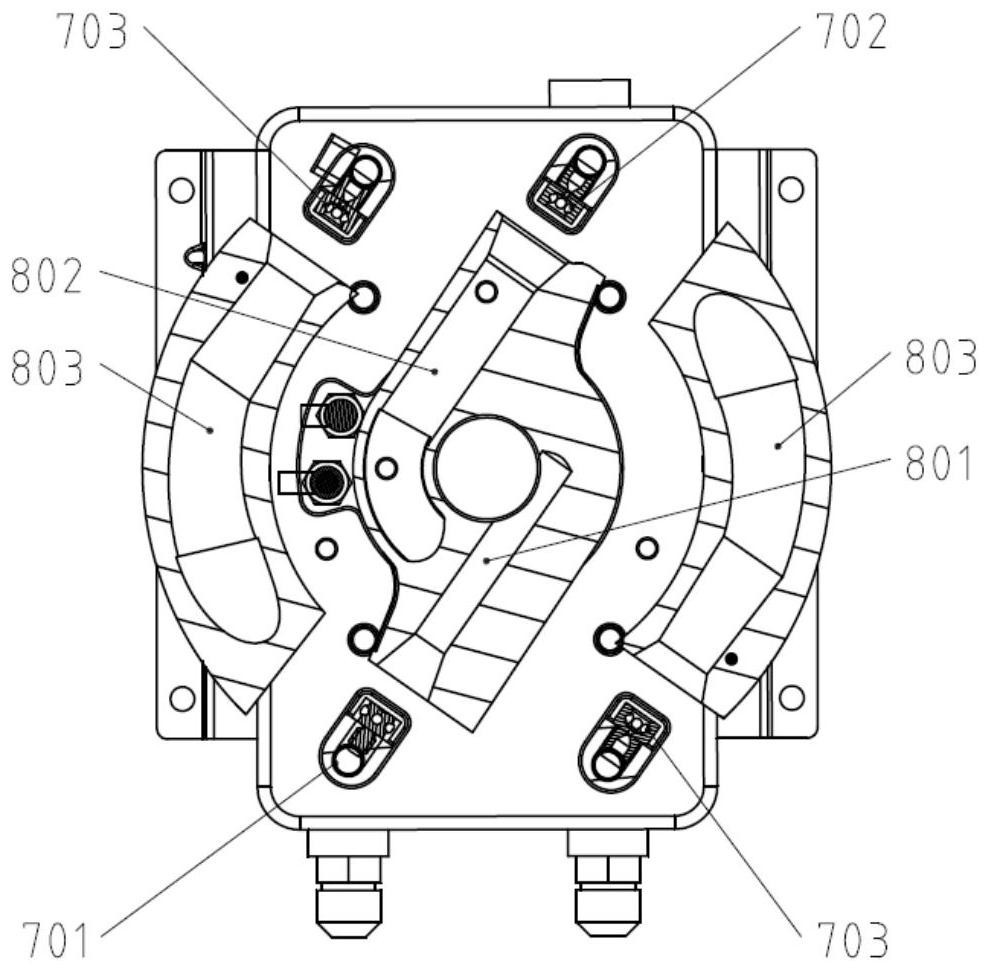

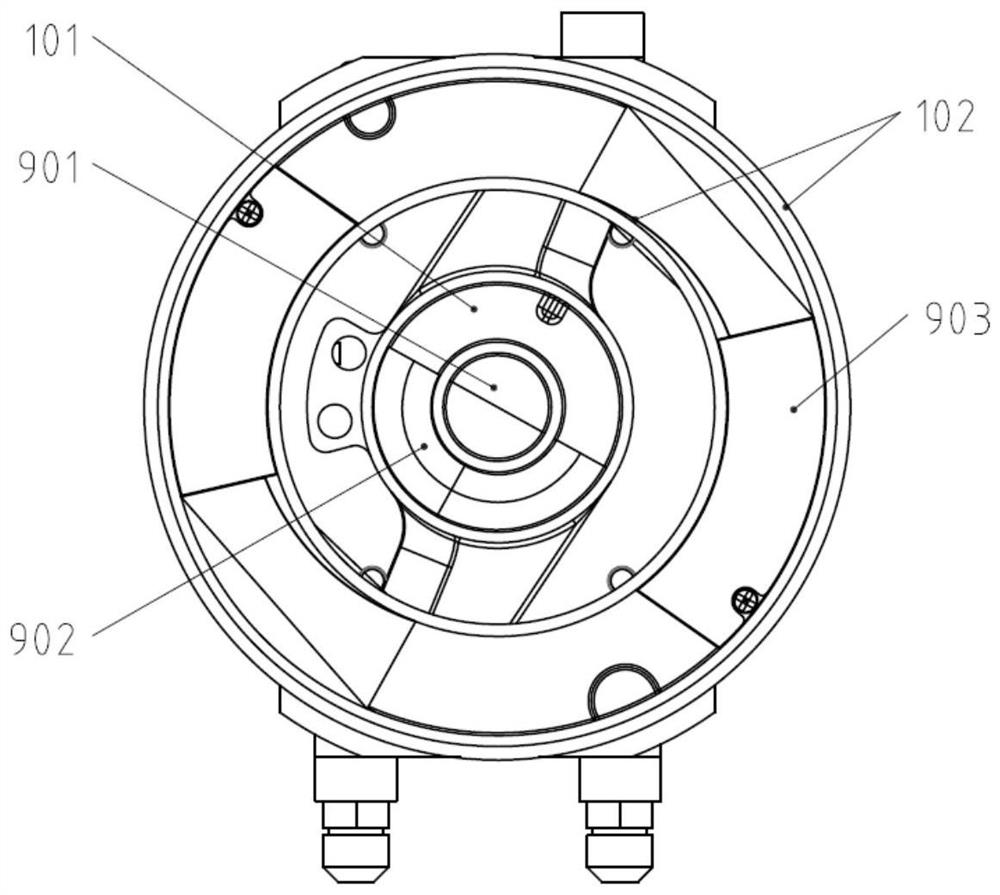

[0061] Such as Figure 9-12 The burner shown has the same technical scheme as that of Embodiment 1, including a first gas channel 2, a second gas channel 3, an inner ring gas mixing chamber 4, a middle ring gas mixing chamber 5 and an outer ring gas mixing chamber. The burner body 1 of the cavity 6 . There are four nozzles 7 inside the burner body 1 , and the four nozzles 7 are all located on the base 103 . The inlet of one nozzle 7 is communicated with the first gas channel 2 and the outlet is communicated with the inner ring gas mixing chamber 4 , as the inner ring nozzle 701 . The inlet of one nozzle 7 is communicated with the second gas passage 3 and the outlet is communicated with the middle-ring gas mixing chamber 5 , which serves as the middle-ring nozzle 702 . The inlets of the two nozzles 7 are communicated with the second gas channel 3 and the outlets are communicated with the outer ring gas mixing chamber 6 as outer ring nozzles 703 . The outer ring nozzles 703 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com