Non-contact rotary power transfer system

A technology of power transmission and power inversion, which is used in the conversion of AC power input to DC power output, radiation diagnosis data transmission, and output power conversion devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

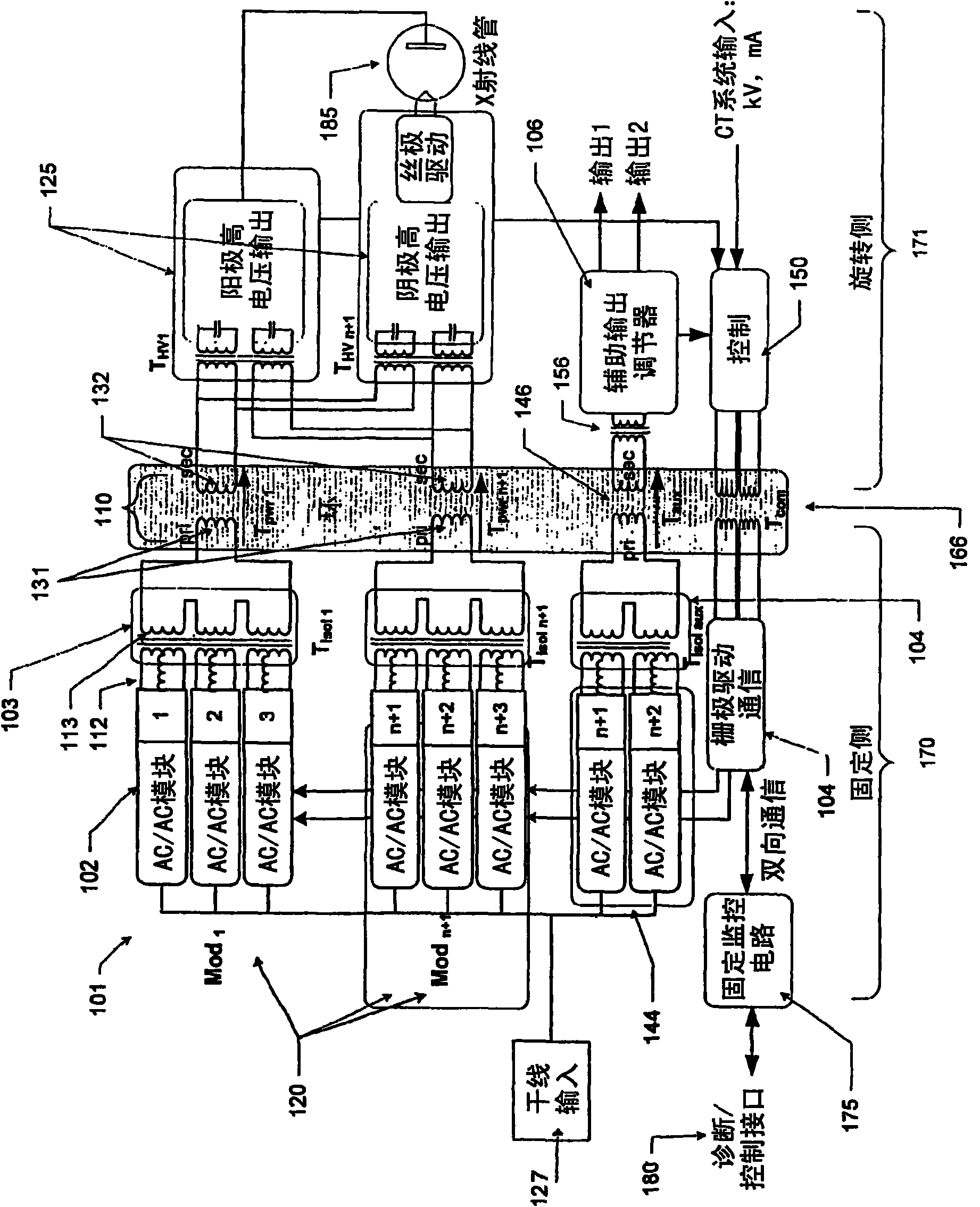

[0023] Systems and methods are described that increase the available space on a rotating gantry by relocating high voltage, high power inverters and auxiliary power supplies to a fixed frame, without physical contact (such as brushes) Power is delivered to the rotating system under high conditions and at high speeds (eg, greater than about 300 RPM). Specifically, a resolver is described that couples power between a stationary side and a rotating side. Isolation and decoupling of the mains supply is achieved by an isolation and summing transformer driving the primary winding of the resolver in a multi-phase configuration. Applications in which the contactless power delivery system described in this disclosure may be used include, but are not limited to, CT (Computed Tomography) systems.

[0024] figure 1 A contactless power transfer system 100 according to one embodiment of the present disclosure is shown. although figure 1 The example shown in can be used as Figure 11 Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap