Method for mixing fluids efficiently

A fluid and efficient technology, used in mixing methods, fluid mixers, gas and gas/vapor mixing, etc., can solve the problems of time-consuming, manpower, material resources and equipment investment, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

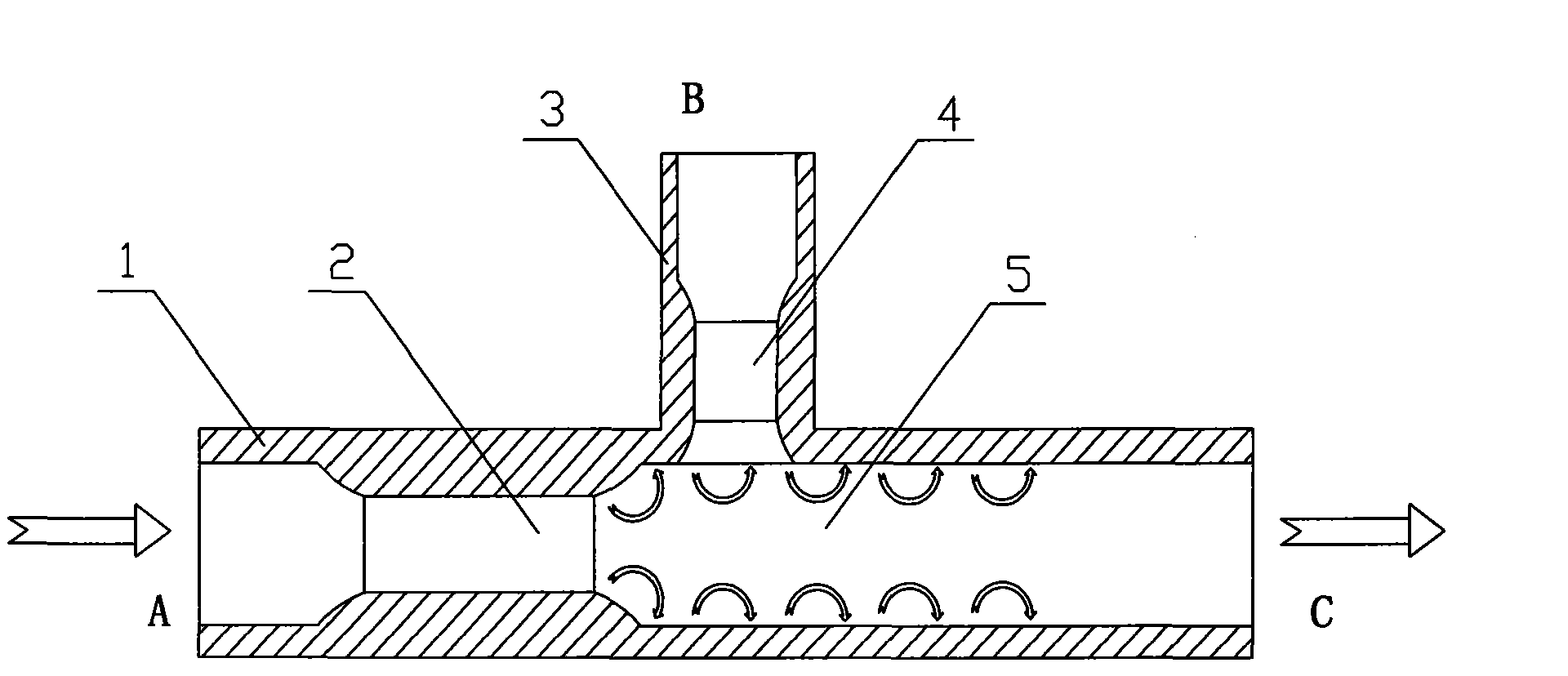

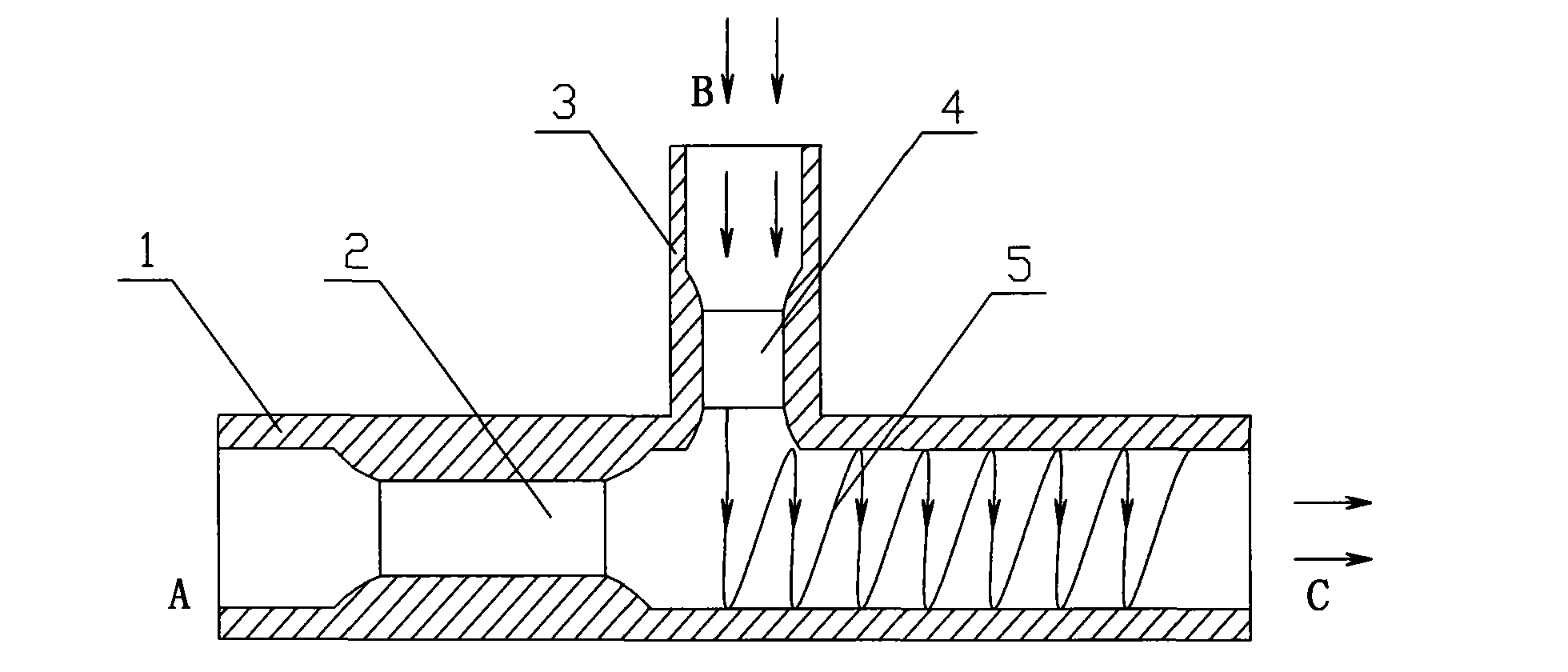

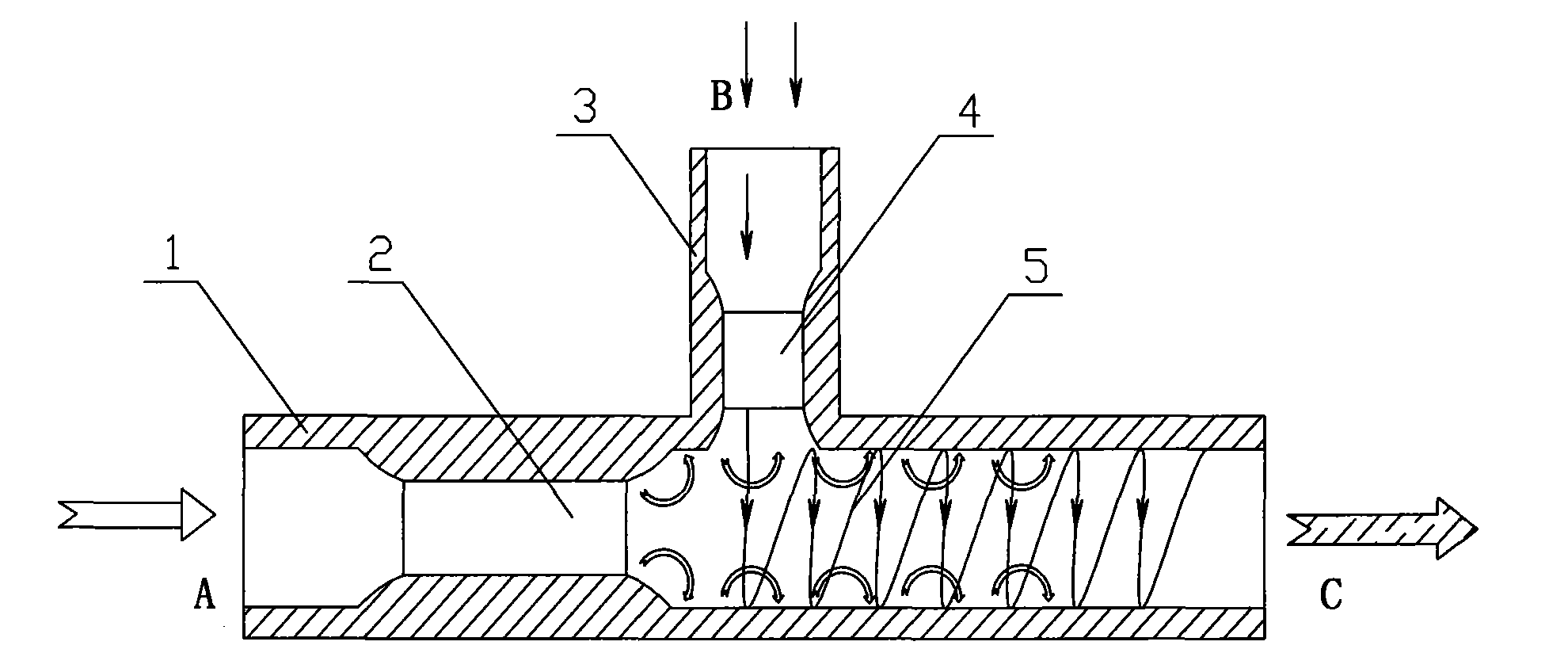

[0014] A method for highly efficient mixing of fluids, characterized in that: the first fluid is injected into the head end of a horizontal tube with a reduced-diameter acceleration section at high pressure, so that the first fluid is accelerated in the horizontal tube through the horizontal-tube reduced-diameter acceleration section, and Numerous high-speed rotating vortices are generated on the rear side of the diameter-reducing acceleration section of the horizontal tube; the vortex is generated around the inner wall of the horizontal tube; the section where the vortex is generated in the horizontal tube is called the mixing zone;

[0015] At the same time, the second fluid is injected into the horizontal tube under high pressure from the head end of the side tube provided on the side wall of the horizontal tube, and the second fluid fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com